dmattmul

Well Known Member

First, I've loved my WW 3 blade 300 series prop for its smoothness and power both climb and cruise. No issues removing lower cowling and have not split the bottom cowling.

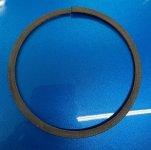

Recently I was doing the normal walk around inspecting and pulling on the tips of the blades and noticed one that seemed "a little sloppy". Not remembering the exact play allowed I looked it up and seemed to be greater than the tolerance. After a call to WW Ohio (They do not exist any longer) called California and they had me inspect the blade root for possible loss of shim. Sure, enough it had departed the propellor. It fits under the heavy-duty retaining ring. See pics. I don't think this was a safety of flight issue or at least not immediate but worth checking on the walk-around.

Service and attention to detail was excellent from the factory!!

Recently I was doing the normal walk around inspecting and pulling on the tips of the blades and noticed one that seemed "a little sloppy". Not remembering the exact play allowed I looked it up and seemed to be greater than the tolerance. After a call to WW Ohio (They do not exist any longer) called California and they had me inspect the blade root for possible loss of shim. Sure, enough it had departed the propellor. It fits under the heavy-duty retaining ring. See pics. I don't think this was a safety of flight issue or at least not immediate but worth checking on the walk-around.

Service and attention to detail was excellent from the factory!!