Oh man, thanks for this. I am installing Beringer brakes w/ AS Flightlines hoses and fittings. The Beringer brakes are backordered from Vans. No clue when they will arrive. Do you know if I will have access to install the AN flare fitting after finishing the fuselage?

I tried very gently threading the elbows into the gear brace but they were tight. In fact, on one of them I couldn't get the elbow started. I didn't want to force it so I decided to clean the threads first. I have a little (very little) Akzo primer overspray in the holes which is probably part of the problem.

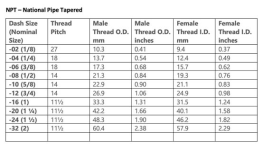

I've spent an hour trying to figure out which tap I need. I'm just dizzy. NPT, MPT, FIP, HSS,...As you can tell, I'm no machinist - or is that a pipe fitter?

Will this work:

https://www.amazon.com/dp/B0C7H4JQX...=d2lkZ2V0TmFtZT1zcF9kZXRhaWxfdGhlbWF0aWM&th=1