Manchu16

Active Member

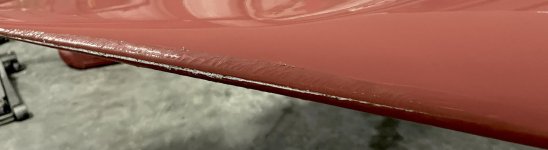

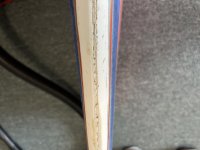

Stupid mistake, but it happened. Scraped the wing tip on a chain link pole by the fuel pump. Not the builder, so apologize for the questions.

The edge does not appear to be split, but there in a nice gouge where it ran along the pipe. It appears that the damage is mainly in filler right now, but hard to tell without sanding it out. The damage is roughly 20” from tip to the start.

I am going to feather in to the glass where the paint wrinkles are on the top and bottom. I was going to run a ~1” band and then a ~2” band using 4oz tape. Depending on the profile I may also use a 1/2” band to start. The glass will be centered along the tip edge. As it gets closer to the tip, I am just going feather out the 2” and just use a single 1” band. Going to use west systems epoxy and will try to use peal ply to weigh it down if I can get the shape to hold.

Will sand and then will mix up a slurry of micro to finalize the shape. As I get to the last 6” near the tip not sure I really can do anything with glass and will just use the micro to shape it. I am planning on making a few templates to make sure that I keep the profile as true to the original tip as possible.

I have some experience repairing glass on boats, but none on aircraft. Please poke holes in my approach.

The edge does not appear to be split, but there in a nice gouge where it ran along the pipe. It appears that the damage is mainly in filler right now, but hard to tell without sanding it out. The damage is roughly 20” from tip to the start.

I am going to feather in to the glass where the paint wrinkles are on the top and bottom. I was going to run a ~1” band and then a ~2” band using 4oz tape. Depending on the profile I may also use a 1/2” band to start. The glass will be centered along the tip edge. As it gets closer to the tip, I am just going feather out the 2” and just use a single 1” band. Going to use west systems epoxy and will try to use peal ply to weigh it down if I can get the shape to hold.

Will sand and then will mix up a slurry of micro to finalize the shape. As I get to the last 6” near the tip not sure I really can do anything with glass and will just use the micro to shape it. I am planning on making a few templates to make sure that I keep the profile as true to the original tip as possible.

I have some experience repairing glass on boats, but none on aircraft. Please poke holes in my approach.

Attachments

Last edited: