charlesmc

Member

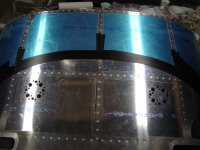

I went ahead, blindly followed the plans, and riveted on the top forward fuselage skin to the underlying ribs. It is not attached to the fuselage and is currently sitting off the aircraft.

In researching wiring, I found that it is extremely popular to NOT rivet the skin on for ease of wiring.

How tough is it going to be to install avionics / forward wiring with the skin in place?

I was thinking of creating a wood frame that would pop the forward fuselage top up at an angle to make it a little easier to work on. Would need some service loops for the wiring and would try to keep those as short as possible.

I also see people turn the assembly upside down and install avionics on the bench.

Should I bite the bullet and drill out the rivets and then rivet the skin back on later? Or just buy all new parts and assemble in stages?

-Charles

In researching wiring, I found that it is extremely popular to NOT rivet the skin on for ease of wiring.

How tough is it going to be to install avionics / forward wiring with the skin in place?

I was thinking of creating a wood frame that would pop the forward fuselage top up at an angle to make it a little easier to work on. Would need some service loops for the wiring and would try to keep those as short as possible.

I also see people turn the assembly upside down and install avionics on the bench.

Should I bite the bullet and drill out the rivets and then rivet the skin back on later? Or just buy all new parts and assemble in stages?

-Charles