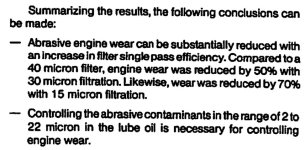

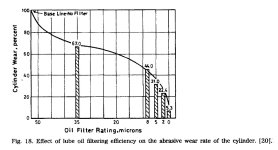

Or to the contrary, none have shared why abrasives in the 5 to 40 um range significantly contribute to engine wear. I see lots of planes with and without filters at my airport, most do a once a year oil change and I have never noticed a correlation to the filtered ones making TBO and the screeened ones not. Just my observation.Some share your perspective. None have shared why they believe "originally designed with nothing more than a screen" makes a Lycoming immune to abrasives in the 5 to 40 µm range.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Filter Test Results

- Thread starter DanH

- Start date

BillL

Well Known Member

These are part of the pulsator and vibration test standards run at each 1/4, 2/4, 3/4 turns. My information is 20+ yrs old, but when I was in the business - -an oil filter test engineer said he had tested (pulse & vibration) hundreds of filters and none came loose even at the 1/4 turn. I don't have a positive test to say 3/4 will never come loose on our airplanes, but previous definitive tests say they won't. Thousands of diesels running tens of thousands of hours I never saw, or heard of this happening .that is why most auto filters say contact + 3/4 turn.... It equals 16 to 18 ft lbs. without using a torque wrench.

Very simple and it has worked for millions of filter changes.

DON'T USE HAND TIGHT + 3/4 TURN...... Use only CONTACT then 3/4 turn.

On your next filter change, screw on to contact and mark the top of the filter, then torque it to 17ft#

and see where the mark on the filter ends up.

As a result of this test, thanks Dan, I have zero confidence in anything on the basis it has PMA approval by the FAA. I can not understand why this is not a criminal violation for the Challenger filters.

Lastly. https://ph.baldwinfilters.com/baldwin/en/product-list/baldwin-spin-on-lube-filters

This link can provide searching for size, thread and then provide efficiency, bypass pressures etc. Mostly diesel engines which would have the same high burst and pulse capability we desire to have. One clue is the dome shape of the base.

Toobuilder

Well Known Member

I think the better question is "how many parts are reusable at TBO" between a filtered and a screened engine...I see lots of planes with and without filters at my airport, most do a once a year oil change and I have never noticed a correlation to the filtered ones making TBO and the screeened ones not...

Excellent question, and the answer is?I think the better question is "how many parts are reusable at TBO" between a filtered and a screened engine

Toobuilder

Well Known Member

I'm not an overhaul facility so I cant directly validate the results

But I know where I'd place my bets.

BTW, are we actually debating whether a filter is better than a screen? I lost track.

But I know where I'd place my bets.

BTW, are we actually debating whether a filter is better than a screen? I lost track.

BillL

Well Known Member

A few thoughts.

Filtration is frequently considered to be about efficiency, but it is really about how much material (and what) passes through the filters. We typically think that something with 98% efficiency is really good and very close to 99% efficiency. But the 98% filter passes twice as many particles as the 99% filter.

If an engine is in catastrophic failure mode, it might have a couple of hours, or a couple of minutes before it ceases making power. The oil filter is also part of a safety net to extend that process and provide some measure of safety to land safely. Many examples of fatal events where a few hundred yards were the difference in making the field. Personally, I had rather have a filter that allows that extension. It shouldn't add to the failures (leak, burst, internal crushing, debris generation) and while it lives in normal life provides some value in longer TBO and extending oil change periods, thus lowering the costs invested in maintaining the functionality.

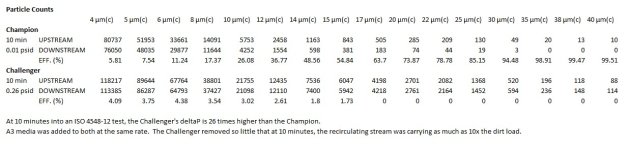

Kudos to Dan for collecting and distributing this data. Hopefully, will save someone's life by better filter selection. The final result was not surprising to me but truly shocking. A screen type "filter"has the ability to provide useful filtration, albeit at the expense of capacity. These "screen" type filters did not even provide what is possible in that design category, very disappointing, and revealing for the weakness in the PMA process. Someone in the FAA needs to justify the approval based on this data.

Pete Howell has posted the internals of his engine at over 2000 hrs. I have never seen such good looking bearings in an aircraft engine and is a testament to good maintenance. I don't recall seeing Vlads engine internals.

Thanks for reading this far.

For those interested in the test details you might go to bobistheoilguy.com and look at the testing there on filters. Caution advised, it is a slippery slope down the validation rabbit hole

Filtration is frequently considered to be about efficiency, but it is really about how much material (and what) passes through the filters. We typically think that something with 98% efficiency is really good and very close to 99% efficiency. But the 98% filter passes twice as many particles as the 99% filter.

If an engine is in catastrophic failure mode, it might have a couple of hours, or a couple of minutes before it ceases making power. The oil filter is also part of a safety net to extend that process and provide some measure of safety to land safely. Many examples of fatal events where a few hundred yards were the difference in making the field. Personally, I had rather have a filter that allows that extension. It shouldn't add to the failures (leak, burst, internal crushing, debris generation) and while it lives in normal life provides some value in longer TBO and extending oil change periods, thus lowering the costs invested in maintaining the functionality.

Kudos to Dan for collecting and distributing this data. Hopefully, will save someone's life by better filter selection. The final result was not surprising to me but truly shocking. A screen type "filter"has the ability to provide useful filtration, albeit at the expense of capacity. These "screen" type filters did not even provide what is possible in that design category, very disappointing, and revealing for the weakness in the PMA process. Someone in the FAA needs to justify the approval based on this data.

Pete Howell has posted the internals of his engine at over 2000 hrs. I have never seen such good looking bearings in an aircraft engine and is a testament to good maintenance. I don't recall seeing Vlads engine internals.

Thanks for reading this far.

For those interested in the test details you might go to bobistheoilguy.com and look at the testing there on filters. Caution advised, it is a slippery slope down the validation rabbit hole

Seriously, this observation has relevance? Essentially, an insignificantly small sample of engines that don't run often (less than 25 hours/year (screened) or 50 hrs/yr (filtered) derived from your statement). This, and/or they don't getting proper oil changes as most OEM suggest oil change intervals every four calendar months. Environmental/material factors are probably their biggest threat and none would make an honest TBO unless, possibly they were dry climate based. There are other factors. The wisdom and experience shared on this forum is top notch. Like anywhere else, anecdote should be treated with extreme prejudice.Or to the contrary, none have shared why abrasives in the 5 to 40 um range significantly contribute to engine wear. I see lots of planes with and without filters at my airport, most do a once a year oil change and I have never noticed a correlation to the filtered ones making TBO and the screeened ones not. Just my observation.

I made an error when writing post #1, since corrrected. Although the specified fluid for the majority of the ARP 1400-B performance metrics is 50W AD aviation oil, I missed a sentence in ARP-1400-B (par. 5-4-7) specifying J1858 for multipass efficiency testing. The fluid would be MIL-H-5606, same as the ISO-4548-12 test.

So....

What is good enough?

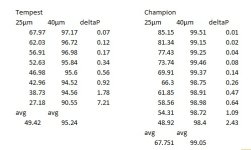

The agreed standard for piston aviation oil filters is SAE ARP 1400- Rev B. The standard covers all aspects of filter construction and performance (example, burst pressure), but the key point here is filtration efficiency at two particle sizes. ARP 1400-B specifies the SAE J1858 multipass proceedure for measuring filtration, essentially identical to ISO-4548-12. The minimum required performance is >75% at 25 µm, and >90% at 40 µm, with 15 grams retention, and a terminal deltaP of 8 psi.

The viscosity of 50W AD aviation oil at 180F (+ or - 5) is roughly 32 cSt, vs 15 cSt for the MIL-H-5606 fluid used for ISO 4548-12 and J1658 tests. As a general rule, higher viscosity would be expected to reduce capture efficiency.

So....

What is good enough?

The agreed standard for piston aviation oil filters is SAE ARP 1400- Rev B. The standard covers all aspects of filter construction and performance (example, burst pressure), but the key point here is filtration efficiency at two particle sizes. ARP 1400-B specifies the SAE J1858 multipass proceedure for measuring filtration, essentially identical to ISO-4548-12. The minimum required performance is >75% at 25 µm, and >90% at 40 µm, with 15 grams retention, and a terminal deltaP of 8 psi.

The viscosity of 50W AD aviation oil at 180F (+ or - 5) is roughly 32 cSt, vs 15 cSt for the MIL-H-5606 fluid used for ISO 4548-12 and J1658 tests. As a general rule, higher viscosity would be expected to reduce capture efficiency.

Last edited:

The minimum required performance is >75% at 25 µm, and >90% at 40 µm, with 15 grams retention, and a terminal deltaP of 8 psi. Here neither Tempest or Champion met the >25 µm requirement.

Didn't this test go to 10 psid? Maybe the increased deltaP of 2 PSI was enough to cause a slight drop in efficiency?

Or to the contrary, none have shared why abrasives in the 5 to 40 um range significantly contribute to engine wear.

Actually I have. I'll repeat a few previous illustrations below. There are more on the way.

I see lots of planes with and without filters at my airport, most do a once a year oil change and I have never noticed a correlation to the filtered ones making TBO and the screeened ones not. Just my observation.

When speaking with a friend a few days ago, I suggested the best analogy might be health statistics for smokers. If we look at life expectancy statistics for heavy smokers, we'll see some percentage live to 100 years old despite the health effects, while some percentage reach normal life expectancy, and some percentage die earlier than normal. When compared, we see higher percentages of non-smokers reaching 100, more living a normal lifespan, and fewer dying early.

Filtration is much the same. Some engines will go past TBO, some just to TBO, and some will die early. Better filtration improves the odds, but just like smoking, we're not going to convince everyone.

Schwaner:

Heywood:

Staley:

Pocock (from 1956!)

Didn't this test go to 10 psid? Maybe the increased deltaP of 2 PSI was enough to cause a slight drop in efficiency?

That's a fair point. I reviewed the data tables, averaging the efficiencies after eliminating all data points at 8 psi deltaP and above. It still appears neither Tempest or Champion would meet the ARP 1400-B standard (>75%) for 25µm.

Last edited:

I'm thinking that if my Lycoming is loading the filter with enough crap to bypass, i'll take ANY extension to flying time that I can put my hands on, to give me more margin to reach the next airport. Even if that means carrying an unused bypass valve around for the life of my engine. Wix does make bypass filters, surely there is one that fits our application. I'm with you on burst pressure though, engine temperature management seems to be an adequate way to mitigate that risk.- IF your Lycoming IS loading an automotive filter enough to bypass, then you have BIG problems under the hood and the slightly higher bypass pressure of the “aviation” filter is not going to help you much. - Unless you are returning from a combat mission and you need another 10 minutes of flying time to reach friendly lines before the engine finally locks up.

@ DanH.

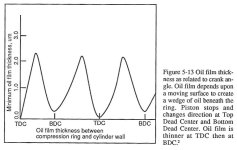

The prevailing mindset seems to be ring/cylinder wear; maybe because the adverse effects could show up in a leak test

The sliding contact clearances are easy, even for me. Got any info on main bearing or connecting rod clearances/film thicknesses? Seems to me, filtration level consequences would be higher where soft babbitt is involved and/or associated rectification requiring engine pull/case splitting would be required.

The prevailing mindset seems to be ring/cylinder wear; maybe because the adverse effects could show up in a leak test

The sliding contact clearances are easy, even for me. Got any info on main bearing or connecting rod clearances/film thicknesses? Seems to me, filtration level consequences would be higher where soft babbitt is involved and/or associated rectification requiring engine pull/case splitting would be required.

Toobuilder

Well Known Member

Your point is valid, but it is an edge case. Pulling on that thread, if you look at the delta P curve, it’s is anything but linear. In real terms, the pressure rise goes almost vertical as the media reaches saturation so if there is a choice between a 13 PSI bypass Champion and 11 PSI Wix, how much actual operating time passes when each starts to bypass? And even then, the bearings may survive the time eating the unfiltered oil until the next fuel stop.I'm thinking that if my Lycoming is loading the filter with enough crap to bypass, i'll take ANY extension to flying time that I can put my hands on…

I agree the premise of “longer filtration is better”, but if your engine is making enough metal for the bypass PSI to be a discriminator, you are having a very bad flying day.

Last edited:

The sliding contact clearances are easy, even for me.

We're not going to convince the "dirt don't hurt" believers without an official note from Lycoming, and some not even then. Spare yourself...

glider_rider

Active Member

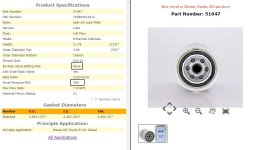

The oil filter adapter in my 390 does have a pressure relief valve. Googling around I found the VIX 51551,There is no one best filter for a Lycoming. Takes at least two...

Does your filter adapter incorporate a built-in bypass valve? If so, you want a 48110 equivalent, i.e no bypass in the filter.

no bypass and no anti-drainback valve. Any thoughts or recommendations?

Won’t fit — needs a 3/4-16 nipple, the filter you linked to uses 1”x12The oil filter adapter in my 390 does have a pressure relief valve. Googling around I found the VIX 51551,

no bypass and no anti-drainback valve. Any thoughts or recommendations?

glider_rider

Active Member

THXWon’t fit — needs a 3/4-16 nipple, the filter you linked to uses 1”x12

and if we want to be REALLY, REALLY cautious, we can just braze the filter to the housing.To be REALLY cautious shouldn’t the safety wire run thru the slot in the worm gear screw head, to keep it from backing off?

The reusable cable and hose clamp takes less than a minute to install.

I don't see any problem using a filter that has a bypass valve with the adapter that also has a bypass valve installed.

You get double the protection. A WIX filter 51515 will bypass 2-4#s before the Lycoming bypass.

I don't see any problem using a filter that has a bypass valve with the adapter that also has a bypass valve installed.

You get double the protection. A WIX filter 51515 will bypass 2-4#s before the Lycoming bypass.

Attachments

...not to be confused with the tested 51515The oil filter adapter in my 390 does have a pressure relief valve. Googling around I found the VIX 51551,

I don't see any problem using a filter that has a bypass valve with the adapter that also has a bypass valve installed.

You get double the protection. A WIX filter 51515 will bypass 2-4#s before the Lycoming bypass.

...which protects the filter (i.e. prevents element crush), but not the engine. I'm thinking about startup with 50W viscosity.

The 51515 performed well in the filtration test, but I'm sure there are choices with similar or better performance, and better physical specs. Already pointed a few with significantly higher can strength and bypass values closer to Lycoming spec. There's a subtle aspect to a filter designed with a higher internal bypass pressure rating...the element and core tube must be stronger. I'm looking around, as are others.

Break.

Need a no-bypass filter (48110 substitute) for use on the Lycoming adapter? Look at a 51647. 390 burst, decent beta values. Not endorsement, but a good candidate.

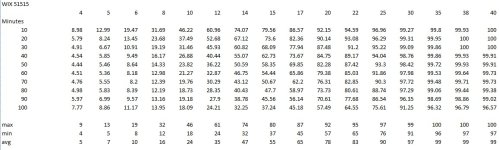

About those beta ratios. So far I've been expressing filter efficiency in percentages, as everyone understands percentage. They can also be expressed as a beta values. Beta can be understood as "given this many particles, one gets through". Wix generally publishes a dual beta, but the format is a bit whacky. Rosetta Stone below.

Note Wix claims a 2 beta, i.e. 50% at 6 µm, but our 51515 results show 10% at 6 µm. Likewise, a 20 beta is 95%, but our results show 78% average at 20 µm. It is pretty close to 95% for a brand new clean filter. Point is, the actual values are good, but they're not what Wix is claiming.

Wix 4548-12 efficiency values. Microns at top, table in percentages.

Last edited:

Indeed - I've bought a few filters, and watched a few YT videos of filter comparisons, and the apparent lack of manufacturing consistency of car/truck filters one of the things that makes me a bit uncomfortable. Even big brands seem to manufacture in different places, and they sometimes look very different. One of the things I was hoping to leave behind with the reusable, but clearly not.I'm looking around, as are others.

I think there is a biz opportunity for someone to create a machined case that will use one of the disposable cellulose filters that don't have a can. Those seem to be very consistent quality, and are often packaged in clear plastic, showing real pride in the product. Here's an example:

Anyone have a good source for the common 3/4-16 nipple, other than removing them from old aircraft filters?

3/4x16 Nipple for Oil Filter Mount - Pegasus Auto Racing Supplies

This 3/4-16 nipple for an oil filter mount has an overall length of 1". The Knurled section, 3/8" from one end holds the nipple in the filter mount or engine block preventing unthreading.

This looks like it...

procomp makes them and they have the knurling in the center to lock it into the adapter. I found them when looking for one several years ago, but ended up just making one on the lathe. Summit is probably a good source.Anyone have a good source for the common 3/4-16 nipple, other than removing them from old aircraft filters?

Toobuilder

Well Known Member

Looks exactly like the nipple you can salvage from a Tempest filter.This looks like it...

One note that if you DO go dumpster diving with the intent of harvesting nipples, the Champion has a different thread on the can side. The Tempest is the one you want.

Looks exactly like the nipple you can salvage from a Tempest filter.

One note that if you DO go dumpster diving with the intent of harvesting nipples, the Champion has a different thread on the can side. The Tempest is the one you want.

Got one of those. Seems like a slightly modified thread on what was the filter end, but I'm not sure.

Assuming I re-use it, you guys have been screwing the short thread end (formerly in the filter) into the filter adapter?

Toobuilder

Well Known Member

While fully acknowledging that the search for a Lycoming spec filter is a worthy endeavor, interpretation of data suggests to me that bypass activation of the automotive filter on a cold start is unlikely UNLESS the media is already heavily loaded. And I don’t mean “…normal engine at 49 hours on oil change…” loaded, I mean “…engine is eating itself…” loaded. So the question remains whether we are discussing a possible edge case, or is this likely to happen frequently in normal fleet operations?which protects the filter (i.e. prevents element crush), but not the engine. I'm thinking about startup with 50W viscosity.

Yes, early bypass is a risk…. Just trying to get my head around the probability of that risk manifesting in normal ops.

Toobuilder

Well Known Member

Yes, I think. I do secure it with red locktite though. Never had one come loose.Got one of those. Seems like a slightly modified thread on what was the filter end, but I'm not sure.

Assuming I re-use it, you guys have been screwing the short thread end (formerly in the filter) into the filter adapter?

Planecrazy232

Well Known Member

Everybody needs to watch this video...Where do our filters really come from??

I sitting here with both a Wix 51515XP and a 51348XP in my lap. Both are marked "Made in USA".Everybody needs to watch this video...Where do our filters really come from??

One of our number recently visited an aviation filter production facility. I'm told it's nothing like the above video.

As for car filters, preliminary reading says most of the familiar brands are produced by exactly two manufacturers, Champion Laboratories (First Brands Group) and Mann & Hummel. Wix, for example, is a M&H brand. Both have plants worldwide, including the USA.

From the TV show "How It's Made", Fram filters going together:

Fram is now a First Brands product.

I'm not sayin' we don't get any of those handmade filters, and counterfeit parts are a real problem too. I am sayin' Southeast Asia needs a lot of really cheap filters to keep the tuk-tuks running.

As for car filters, preliminary reading says most of the familiar brands are produced by exactly two manufacturers, Champion Laboratories (First Brands Group) and Mann & Hummel. Wix, for example, is a M&H brand. Both have plants worldwide, including the USA.

From the TV show "How It's Made", Fram filters going together:

Fram is now a First Brands product.

I'm not sayin' we don't get any of those handmade filters, and counterfeit parts are a real problem too. I am sayin' Southeast Asia needs a lot of really cheap filters to keep the tuk-tuks running.

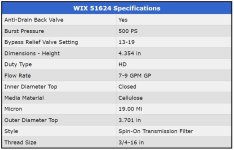

Warren, the 51624 does look interesting. No listed beta values, but they do a claim 19 µm nominal. I'm not aware of an accepted industry definition for "Nominal", but it seems most call it 50% efficiency at the given particle size. Absolute is 75 beta, i.e. 98.7%.As noted earlier....

This would be worth testing.

Like the can pressure and bypass values.

Last edited:

RV7 To Go

Well Known Member

I got mine off Amazon. Summit Racing had them as well as other auto supply stores. I put the short end in the filter with no locktite, just tightened with plastic faced pliers. Never had one come loose and easily removed for the next filter.Anyone have a good source for the common 3/4-16 nipple, other than removing them from old aircraft filters?

Sam Buchanan

been here awhile

Here is the nipple I pulled out of a Tempest 48110-2, the short end was in the filter. This one has a shoulder instead of knurling. The threads are the same on both ends.I got mine off Amazon. Summit Racing had them as well as other auto supply stores. I put the short end in the filter with no locktite, just tightened with plastic faced pliers. Never had one come loose and easily removed for the next filter.

Last edited:

Toobuilder

Well Known Member

If anyone DOES decide to go with the Wix filters, this is a good time to check your local NAPA stores. The "Spring Filter Sale" is going on at my local store now and I'm stocking up on all of my vehicles. The Wix 51515 (NAPA 1515) is $5.33, and the 51647 (Napa 1647) is $12.74 this week. I'm now stocked up for another several years.

rocketbob

Well Known Member

Have a friend with a Cherokee 6 that owns a few Napa stores. They get filters by the semi load. Usually I get a few cases and my price is REALLY GOOD (or not so good, ha). Back in 2006 or so it was this friend's Napa store that myself and a friend wandered into with a new Champion filter in hand and did some examination of filters they had to see what was suitable for a Lycoming. Thats when we figured out we could remove the nipple and permanently install it on the filter adapter. At the time we started using the 1068 which is the shorter version of the 1515. I remember they were $5.00, so $5.33 is still a good price. I can't tell you how many times I've seen people question using an automotive filter after all these years so its nice to see some data that really proves otherwise. Expensive is not best as is in this case.If anyone DOES decide to go with the Wix filters, this is a good time to check your local NAPA stores. The "Spring Filter Sale" is going on at my local store now and I'm stocking up on all of my vehicles. The Wix 51515 (NAPA 1515) is $5.33, and the 51647 (Napa 1647) is $12.74 this week. I'm now stocked up for another several years.

What I would like to see is some data on typical particle size and composition of an average wearing midtime engine. I would suspect most particles in the <40uM range are mostly combustion byproducts consisting of carbon and lead. The usage K&P/Challenger filters hasn't caused any issues in my experience and they do catch visible metallic and non-metallic trash. I'm still comfortable using them.

RV8JD

Well Known Member

K&P has them, but not cheap:Anyone have a good source for the common 3/4-16 nipple, other than removing them from old aircraft filters?

Threaded Fitting – 3/4×16 X 3/4×16 – K and P Engineering

kandpengineering.com

kandpengineering.com

Toobuilder

Well Known Member

The 1068 has been my standard filter for the last few years as well. Last time I stocked up during the Spring Sale 4 years ago, these filters were ~$3.50. I'm on my last one of those now, so the latest sale is timely. Should be good for another 4 years at least....At the time we started using the 1068 which is the shorter version of the 1515. I remember they were $5.00, so $5.33 is still a good price...

Scott Hersha

Well Known Member

After removing the 3/4-16 nipples (2 of them) from my used Tempest filters, I found them in stainless steel at Menards. They looked just like the ones I pulled out of the filters.Anyone have a good source for the common 3/4-16 nipple, other than removing them from old aircraft filters?

dpansier

Well Known Member

Double check the nipple, most likely the ones at Menards are 3/4-16 NPT which are tapered threads. The correct nipple has a 3/4-16 straight thread.After removing the 3/4-16 nipples (2 of them) from my used Tempest filters, I found them in stainless steel at Menards. They looked just like the ones I pulled out of the filters.