My RV-4 kit came with some machine screws that have sharp edges which sits nicely in dimpled skins (wing tanks, forward fuselage skin and so on).

Does anyone know what they are called and where to get them?

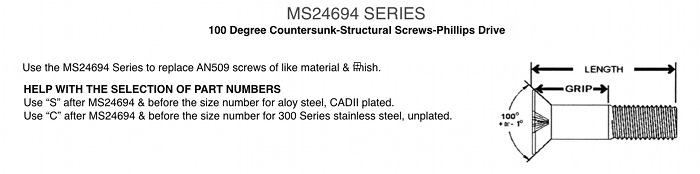

The last batch of MS24694-S5 (supposedly the replacement for the AN509-8R8 screws specified in the plans) I got from ACS have rounded edges that do not at look nice compared to my original screws.

Finn

Does anyone know what they are called and where to get them?

The last batch of MS24694-S5 (supposedly the replacement for the AN509-8R8 screws specified in the plans) I got from ACS have rounded edges that do not at look nice compared to my original screws.

Finn