David Paule

Well Known Member

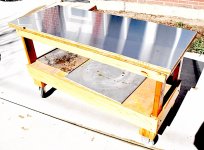

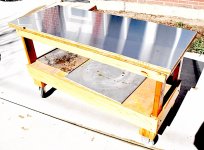

Yeah, this is overkill, but dang, they are nice. They are so easy to clean and they don't mar quickly. Of course you can't readily drill into the top and cleco to it, but you can always drop some plywood or better, that white melamine-faced cabinet sheet and drill into that.

Anyway, if you are going to use stainless, here's the thing: It should not be thinner than 18 gauge or .050" (edited; previously it was "could be").

The white melamine-faced cabinet sheet I mentioned above? That's my first choice, with stainless being my second. But stainless is better for kitchen counters, grill carts, etc.

Dave

Anyway, if you are going to use stainless, here's the thing: It should not be thinner than 18 gauge or .050" (edited; previously it was "could be").

The white melamine-faced cabinet sheet I mentioned above? That's my first choice, with stainless being my second. But stainless is better for kitchen counters, grill carts, etc.

Dave

Last edited: