That’s right. It’s Dan’s fault. He has made me look at protecting cables and pad hoses against heat failure. And I want to say thank you.

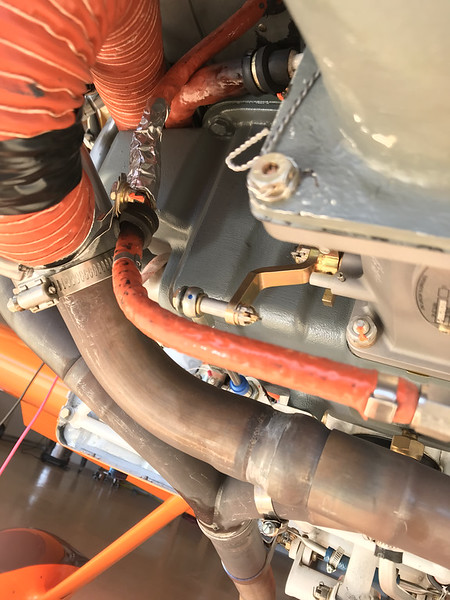

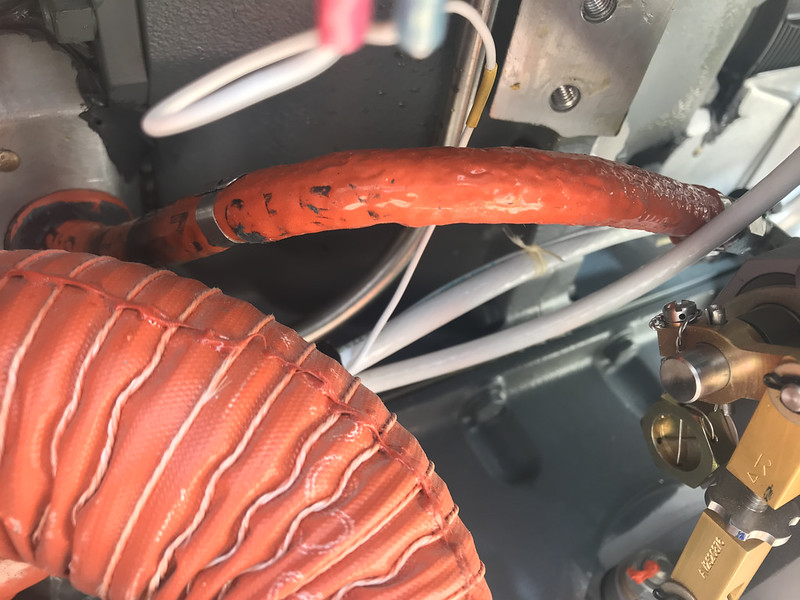

The throttle and mixture cables have some shielding from the mounting bracket but for a little added insurance I added a stainless shield between the bracket and exhaust.

The throttle and mixture cables have some shielding from the mounting bracket but for a little added insurance I added a stainless shield between the bracket and exhaust.