Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Idea to fix…

- Thread starter Xkuzme1

- Start date

Might be a bit late, since the holes are already in there, but in my case I was able to push the wingtip harder to get it to better line up with the leading edge. Just a bit more of a push before I started drilling holes.

If you don't want to try that, then the other ideas should work fine - but might be a lot more work than re-drilling the holes, assuming that can work for you.

If you don't want to try that, then the other ideas should work fine - but might be a lot more work than re-drilling the holes, assuming that can work for you.

PaulvS

Well Known Member

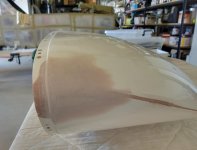

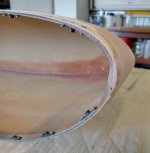

I had the same issue on my 6A and used auto body filler after roughing up the gel coat. Once the filler was hardened I filed and sanded it to final shape.

It helped a bit to push the wing tip forward to minimise the gap that needed to be filled.

It helped a bit to push the wing tip forward to minimise the gap that needed to be filled.

Attachments

Xkuzme1

Well Known Member

I had pushed pretty hard to get the the wingtip where it is. Hard enough that i felt that it could be hard to actually install it.

I had considered the fiberglass slurry (I’ve heard it called peanut butter). Wrap the negative side with wax paper and push the wing tip into place.

I know there are a million ways to skin this cat… I just don’t want to have to fix cracks a couple years from now.

Thanks your your ideas guys.

T

I had considered the fiberglass slurry (I’ve heard it called peanut butter). Wrap the negative side with wax paper and push the wing tip into place.

I know there are a million ways to skin this cat… I just don’t want to have to fix cracks a couple years from now.

Thanks your your ideas guys.

T

wirejock

Well Known Member

Scarf joint

Look up Dans "Sticky" on fiberglass.

1. Sand the area down to bare fiberglass. I don't trust gel coat. Cut layers of fiberglass starting slightly smaller than the gap and increasing in size. Wet and apply. Basically a backwards pyramid shape. The biggest piece encapsulates the entire patch.

2. The foam plug is a great idea as well. Easy to shape a plug and cover with a couple layers of glass.

3. Last idea is a little heavier. Apply a glob of flox. Cover with two layers of saturated fiberglass then peel ply. Squeegee the flox by using a straight edge till it matches the contour.

Look up Dans "Sticky" on fiberglass.

1. Sand the area down to bare fiberglass. I don't trust gel coat. Cut layers of fiberglass starting slightly smaller than the gap and increasing in size. Wet and apply. Basically a backwards pyramid shape. The biggest piece encapsulates the entire patch.

2. The foam plug is a great idea as well. Easy to shape a plug and cover with a couple layers of glass.

3. Last idea is a little heavier. Apply a glob of flox. Cover with two layers of saturated fiberglass then peel ply. Squeegee the flox by using a straight edge till it matches the contour.