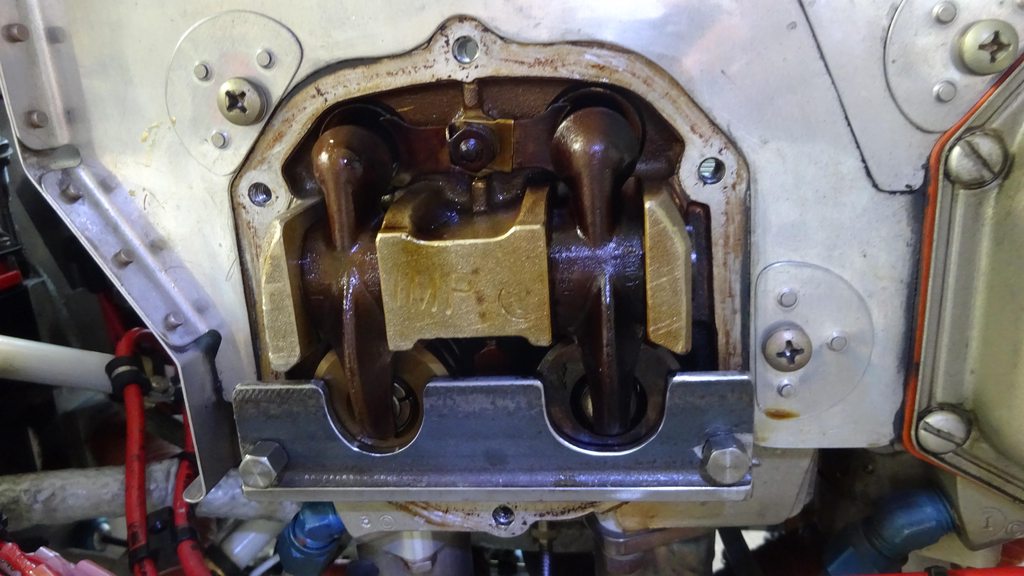

I think you can buy one of these, but I often make my own tools. I am a cheap SOB.

A piece of aluminum plate, two 1/4" hardware bolts, a few other bits, and some welding.

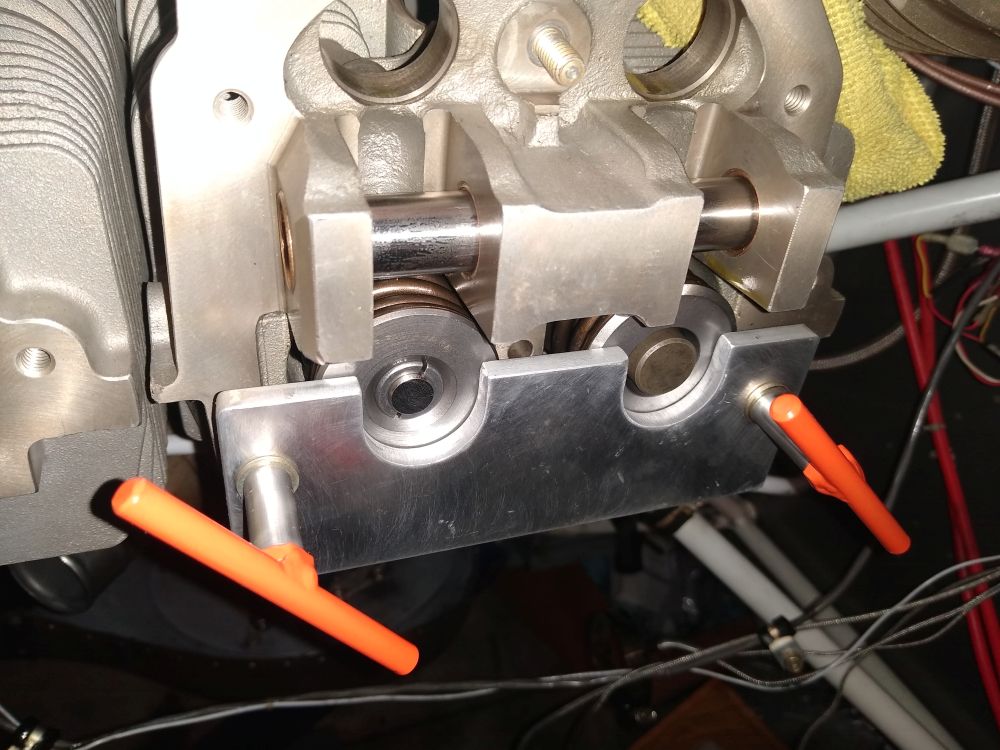

Park the cylinder on TDC, vales closed. Spin the threads into the valve cover screw holes until snug, then one extra turn. Pushes the valve in just a smidge, so no strain on the rocker arm shafts, and they can be pushed out.

A piece of aluminum plate, two 1/4" hardware bolts, a few other bits, and some welding.

Park the cylinder on TDC, vales closed. Spin the threads into the valve cover screw holes until snug, then one extra turn. Pushes the valve in just a smidge, so no strain on the rocker arm shafts, and they can be pushed out.