Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hartzell CS prop Leak Help

- Thread starter mfleming

- Start date

JonJay

Well Known Member

Sorry to see that Michael. That is significant. I don’t think you have a choice.

Western Propeller in Troutdale is probably closest? Mixed reviews but they did mine and were just fine. They are right on the field, so, perhaps you have a buddy there that can fly the prop somewhere for you?

Maybe there’s a shop in Boise or Spokane?

You live in a wonderful place but there are some disadvantages, as you know.

Western Propeller in Troutdale is probably closest? Mixed reviews but they did mine and were just fine. They are right on the field, so, perhaps you have a buddy there that can fly the prop somewhere for you?

Maybe there’s a shop in Boise or Spokane?

You live in a wonderful place but there are some disadvantages, as you know.

Kyle Boatright

Well Known Member

Check the torque on the two bolts right at the hub - in your picture, they are the ones with their heads facing towards the viewer. One is at the leading edge of the prop, one is at the trailing edge. My prop manual is at the airport, but I believe the torque values are in there.

I was sure it was't there after the last flight but I thought maybe I missed it. It was the blade facing down...Grease probably just separated while sitting, Wipe it off and keep flying it, add some fresh grease around 20-30 hrs.

RV8JD

Well Known Member

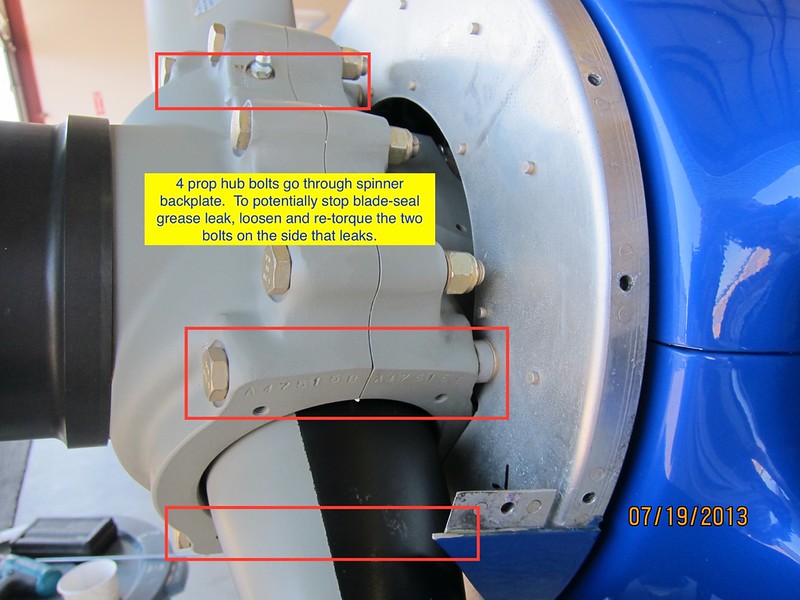

To expand on a previous post:

May not be the OP's issue, but DanH offered this advice many years ago and saved me an unneeded reseal on my previous RV-8's Hartzell prop. Worked like a charm. Here is a pic of my previous RV-8 with some notes:

Attached below is an earlier version of the Hartzell Propeller Owner's Manual No. 115N (61-00-15), Rev 23, Feb 2018 (prior to the introduction of Nyco GN3058 grease).

- Table 3-1 on page 3-7 lists the torques values. "Hub clamping bolts/spinner mtg. nuts 20-22 ft-lbs (28-29 N•m)”.

- See Figure 3 on page 3-10, which shows the hub clamping bolts, like the picture I included above. Obviously, the other 6 bolts that actually hold the hub together should not be disturbed.

- Page 3-11 through 3-13 talks about metal spinner bulkhead installation using those bolts.

- Figure 3-4 on page 3-12 shows the spinner mounting bolts and the spinner bulkhead spacer and stack up, just like on my airplane.

Check to make sure all that makes sense for your prop and hub, as it’s been awhile since I did it.

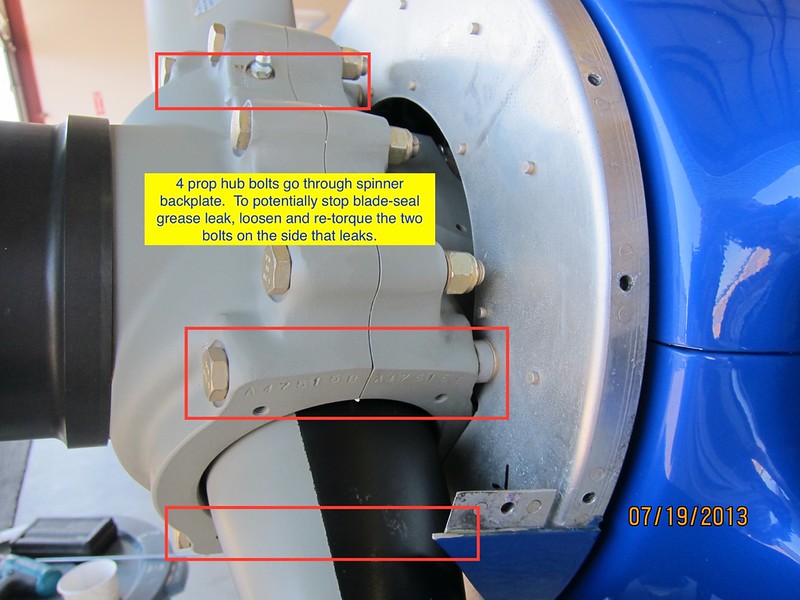

May not be the OP's issue, but DanH offered this advice many years ago and saved me an unneeded reseal on my previous RV-8's Hartzell prop. Worked like a charm. Here is a pic of my previous RV-8 with some notes:

Attached below is an earlier version of the Hartzell Propeller Owner's Manual No. 115N (61-00-15), Rev 23, Feb 2018 (prior to the introduction of Nyco GN3058 grease).

- Table 3-1 on page 3-7 lists the torques values. "Hub clamping bolts/spinner mtg. nuts 20-22 ft-lbs (28-29 N•m)”.

- See Figure 3 on page 3-10, which shows the hub clamping bolts, like the picture I included above. Obviously, the other 6 bolts that actually hold the hub together should not be disturbed.

- Page 3-11 through 3-13 talks about metal spinner bulkhead installation using those bolts.

- Figure 3-4 on page 3-12 shows the spinner mounting bolts and the spinner bulkhead spacer and stack up, just like on my airplane.

Check to make sure all that makes sense for your prop and hub, as it’s been awhile since I did it.

Attachments

Last edited:

It seems to have the consistency of grease. Not sure if 6 or 5. Whatever was installed by Hartzell.Does it have the consistency of grease or oil? Looks like grease but I would agree with Walt if it’s oil.

Also, do you know if it’s Aeroshell 6 or 5?

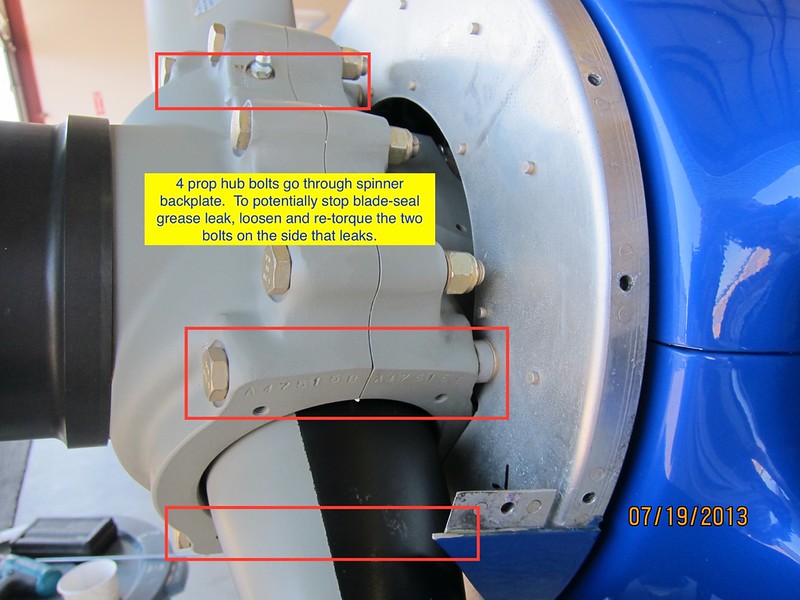

To expand on a previous post:

May not be the OP's issue, but DanH offered this advice many years ago and saved me an unneeded reseal on my previous RV-8's Hartzell prop. Worked like a charm. Here is a pic of my previous RV-8 with some notes:

Attached below is an earlier version of the Hartzell Propeller Owner's Manual No. 115N (61-00-15), Rev 23, Feb 2018 (prior to the introduction of Nyco GN3058 grease).

- Table 3-1 on page 3-7 lists the torques values. "Hub clamping bolts/spinner mtg. nuts 20-22 ft-lbs (28-29 N•m)”.

- See Figure 3 on page 3-10, which shows the hub clamping bolts, like the picture I included above. Obviously, the other 6 bolts that actually hold the hub together should not be disturbed.

- Page 3-11 through 3-13 talks about metal spinner bulkhead installation using those bolts.

- Figure 3-4 on page 3-12 shows the spinner mounting bolts and the spinner bulkhead spacer and stack up, just like on my airplane.

Check to make sure all that makes sense for your prop and hub, as it’s been awhile since I did it.

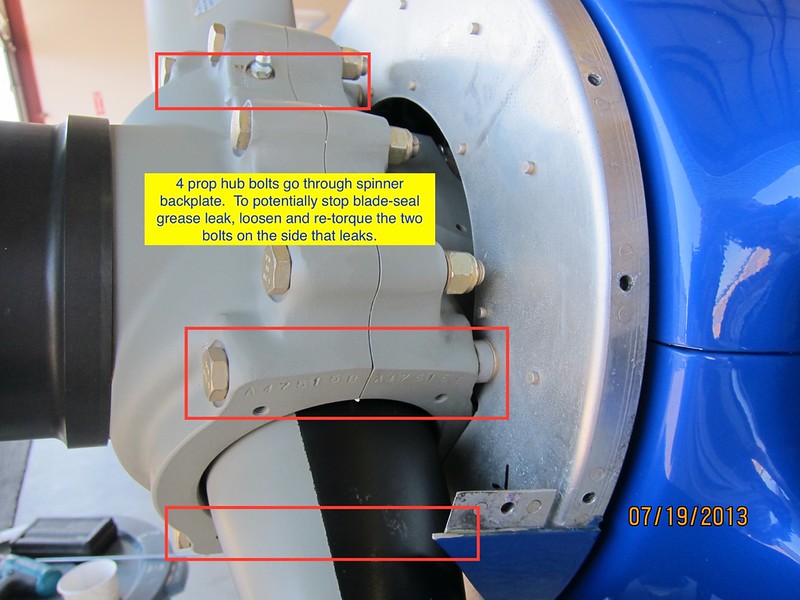

Thanks!To expand on a previous post:

May not be the OP's issue, but DanH offered this advice many years ago and saved me an unneeded reseal on my previous RV-8's Hartzell prop. Worked like a charm. Here is a pic of my previous RV-8 with some notes:

Attached below is an earlier version of the Hartzell Propeller Owner's Manual No. 115N (61-00-15), Rev 23, Feb 2018 (prior to the introduction of Nyco GN3058 grease).

- Table 3-1 on page 3-7 lists the torques values. "Hub clamping bolts/spinner mtg. nuts 20-22 ft-lbs (28-29 N•m)”.

- See Figure 3 on page 3-10, which shows the hub clamping bolts, like the picture I included above. Obviously, the other 6 bolts that actually hold the hub together should not be disturbed.

- Page 3-11 through 3-13 talks about metal spinner bulkhead installation using those bolts.

- Figure 3-4 on page 3-12 shows the spinner mounting bolts and the spinner bulkhead spacer and stack up, just like on my airplane.

Check to make sure all that makes sense for your prop and hub, as it’s been awhile since I did it.

JonJay

Well Known Member

I hope the above suggestions work. I learned something.It may not be either. I forgot they changed grease type mid 2020. Prior to that, 6 was supplied by the factory but had the tendency for the oil to separate. Switching to 5 helped but you could not mix them, so it had to be done at reseal time. This is probably irrelevant to your age of prop.It seems to have the consistency of grease. Not sure if 6 or 5. Whatever was installed by Hartzell.

robertahegy

Moderator/Tech Counselor

This is pretty common to see some grease leaching out the prop hub, especially if it is over greased. Retorque and clean it up to see if it re-appears. Also, sometimes the grease zerk can weep some grease out. It does look like grease to me.

RV8JD

Well Known Member

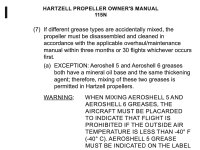

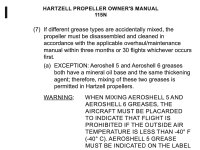

On mixing grease - From pages 6-10 and 6-11 of the HARTZELL PROPELLER OWNER'S MANUAL 115N, Rev 26, August 2023:

NYCO GB3058 grease cannot mixed with Aeroshell 5 or Aeroshell 6. However, Aeroshell 5 and Aeroshell 6 may be mixed, with this proviso:

Also note that it is not possible to purge old grease through the lubrication fittings. To completely replace one grease with another, the propeller must be disassembled and cleaned in accordance with the applicable overhaul manual.

NYCO GB3058 grease cannot mixed with Aeroshell 5 or Aeroshell 6. However, Aeroshell 5 and Aeroshell 6 may be mixed, with this proviso:

Also note that it is not possible to purge old grease through the lubrication fittings. To completely replace one grease with another, the propeller must be disassembled and cleaned in accordance with the applicable overhaul manual.

Last edited:

JonJay

Well Known Member

I always thought that was an odd statment. You can mix them, but you can’t replace them. So, doesn’t accomplish much in the way of oil separation. Anyway, I stand corrected.On mixing grease - From pages 6-10 and 6-11 of the HARTZELL PROPELLER OWNER'S MANUAL 115N, Rev 26, August 2023:

NYCO GB3058 grease cannot mixed with Aeroshell 5 or Aeroshell 6. However, Aeroshell 5 and Aeroshell 6 may be mixed, with this proviso:

View attachment 56431

Also note that it is not possible to purge old grease through the lubrication fittings. To completely replace one grease with another, the propeller must be disassembled and cleaned in accordance with the applicable overhaul manual.

Tooch

Well Known Member

I had the same issue with my prop. Sat for awhile, only had 60 hours on it when it started to spray grease on my wind screen. Since the prop was already 10 years old, I took it to a shop and did an IRAN. They put in the new grease and all has been well for the past 200 hrs. Apparently Aeroshell changed their grease somehow and it is more prone to liquefy and leak.

Clean what you see off of the blades and hub. Label clean blade #1 near the hub with a marker and suspect blade #2. Check the 4 aft spinner bulkhead mounting bolts torque. There should be a placard on the propeller front dome stating what grease it is serviced with. You will have to remove the forward spinner bulkhead to see this.

As others have said, go fly a normal flight and inspect the propeller afterwards.

As others have said, go fly a normal flight and inspect the propeller afterwards.

JonJay

Well Known Member

In my pea brain, there is a big difference between “fog” on the screen caused by oil separating and squeaking past the seal vs a big streak of grease running down the prop. Hence, my initial alarm. I’ve had one, but not the other.

Good luck and report back on what you find.

Good luck and report back on what you find.

Tankerpilot75

Well Known Member

I once experienced a “grease spray “ on my wind screen after a condition inspection which I added some grease to the Hartzell prop hub. Looking inside the spinner I discovered a blob of grease just above a grease zerk. Turns out the grease gun use to regrease the prop had dirt on the tip and transferred a grain or two to the zert preventing it from fully closing.

I was told when I installed the current MT prop on my aircraft that it’s not uncommon for some grease to escape during the first few flights with a new prop. Initially some did leak out but it was minimal and quickly stopped after a few flights.

I think following Walt’s advice is prudent. Wipe it off and monitor the prop for a few flights to see if it reoccurs.

I was told when I installed the current MT prop on my aircraft that it’s not uncommon for some grease to escape during the first few flights with a new prop. Initially some did leak out but it was minimal and quickly stopped after a few flights.

I think following Walt’s advice is prudent. Wipe it off and monitor the prop for a few flights to see if it reoccurs.

Mike S

Senior Curmudgeon

My MT did the same. Stopped after a few flights.I was told when I installed the current MT prop on my aircraft that it’s not uncommon for some grease to escape during the first few flights with a new prop. Initially some did leak out but it was minimal and quickly stopped after a few flights.

Exactly what ours is doing 180 hoursFound this after the last flight. This prop has 100hrs since new, has been dynamically balanced and was in the box just short of 2 years before the first flight last March.

Short of removing it and taking it to a prop shop...what can I do?

View attachment 56398

Update:

I finally got some good weather and flew for 2.5hrs. Slinging grease worse than ever. Removed the prop and it’s currently at the prop shop having new seals installed.

Let this be a warning, don’t let the prop set uninstalled for two years… the seals can take a set.

I finally got some good weather and flew for 2.5hrs. Slinging grease worse than ever. Removed the prop and it’s currently at the prop shop having new seals installed.

Let this be a warning, don’t let the prop set uninstalled for two years… the seals can take a set.

Just for the record. I picked up my prop from the prop shop yesterday. The problem was, there was grey clay like substance packed into the prop. Apparently this caused the leak. I thought the oil coming out of the prop and crank when I removed the prop looked awful. I'm going to have to figure this out before reinstalling the prop.Update:

I finally got some good weather and flew for 2.5hrs. Slinging grease worse than ever. Removed the prop and it’s currently at the prop shop having new seals installed.

Let this be a warning, don’t let the prop set uninstalled for two years… the seals can take a set.

Stevea

Well Known Member

The problem was, there was grey clay like substance packed into the prop. Apparently this caused the leak. I thought the oil coming out of the prop and crank when I removed the prop looked awful. I'm going to have to figure this out before reinstalling the prop.

Does this engine have any run time on it? If so, you might be seeing lead sludge that came from inside the crankshaft bore. Clean out the sludge before replacing the prop.....you're good to go.

FYI: when I had my prop off at ~1000 hrs, the crank bore "didn't look too bad" for sludge build up.....until I started scraping it out (using a paint stir stick). The sludge build up started out thin near the front end, tapering to about 1/8" thick at the back end. Turned out to be quite a bit of it in there.

The engine has 100hrs on it.Does this engine have any run time on it? If so, you might be seeing lead sludge that came from inside the crankshaft bore. Clean out the sludge before replacing the prop.....you're good to go.

FYI: when I had my prop off at ~1000 hrs, the crank bore "didn't look too bad" for sludge build up.....until I started scraping it out (using a paint stir stick). The sludge build up started out thin near the front end, tapering to about 1/8" thick at the back end. Turned out to be quite a bit of it in there.

Mike S

Senior Curmudgeon

Clay is used as a thickener when making some kinds of grease. In certain conditions, like high temps, the oily part can separate out from the grease.The problem was, there was grey clay like substance packed into the prop.

A Guide to Grease Thickeners — Twin Specialties Corp.

Grease thickeners are used to hold base oil and additives in place using a semi-fluid structure, creating proper lubrication of bearings and other machines.

Walt

Well Known Member

Engine oil does not enter the blade cavity area.Does this engine have any run time on it? If so, you might be seeing lead sludge that came from inside the crankshaft bore. Clean out the sludge before replacing the prop.....you're good to go.

FYI: when I had my prop off at ~1000 hrs, the crank bore "didn't look too bad" for sludge build up.....until I started scraping it out (using a paint stir stick). The sludge build up started out thin near the front end, tapering to about 1/8" thick at the back end. Turned out to be quite a bit of it in there.