FireMedic_2009

Well Known Member

I had the engine rebuild was completed at the beginning of Oct. It was stored at a friend’s shop which was air conditioned. In mid Dec I moved the engine to my hangar to install the engine but realized the gear leg bolt holes in the engine mount had an edge distance of 1/16”. So I removed the engine mount and was going to weld tabs on each side of the bolt holes. A friend was going to weld it but has been delayed.

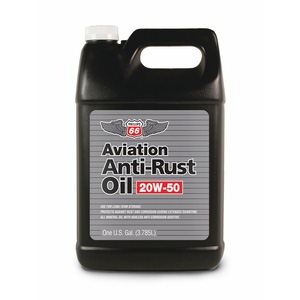

I hope to get the engine mounted and install the wings in 6-8 weeks in order to run the engine. My concern is has rust started to develop on the crank, cam, etc? As far as the cylinders I could remove the plugs and spray oil while rotating the crank. Should I be concerned about rust forming in 6-7 months? Is there anything I can do, short of removing a cylinder and spraying oil inside the case? I live in Tampa where the humidity is high.

Thanks

I hope to get the engine mounted and install the wings in 6-8 weeks in order to run the engine. My concern is has rust started to develop on the crank, cam, etc? As far as the cylinders I could remove the plugs and spray oil while rotating the crank. Should I be concerned about rust forming in 6-7 months? Is there anything I can do, short of removing a cylinder and spraying oil inside the case? I live in Tampa where the humidity is high.

Thanks