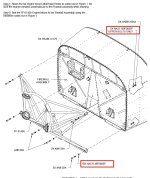

The engine mount attachment method for the RV 14 is different from all the other RV models.

The bushing welded into the engine mount is not a net fit diameter to the bolt being used. I think it’s ID is 1/2”, and the bolt is 3/8”.

It is purposely larger to accommodate for a slight amount of mismatch between the overall dimensions of the engine mount and the location of the actual bolt holes in the firewall.

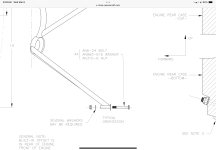

During the install process, the large flange washer on the backside of each bolt location gets match drilled to the hole in the firewall which will allow it to take all of the lateral loads at each attachment joint. For the tension loads, it doesn’t matter if the bolt is a close fit to the sleeve in the engine mount, so what the OP is seeing is normal.

Double check the plans though, if memory serves me, I think there is a different washer used other than just a plain AN960.