mc607

Well Known Member

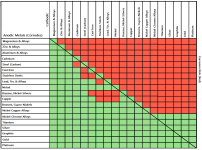

What is the proper hardware to use on this power bus? SS, regular AN cad plated?

www.steinair.com

www.steinair.com

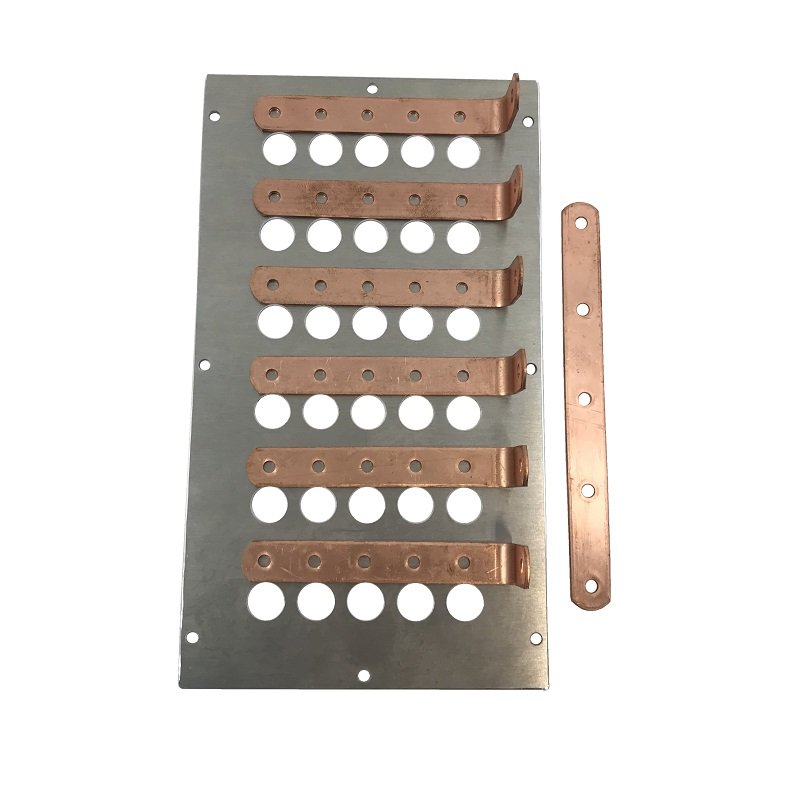

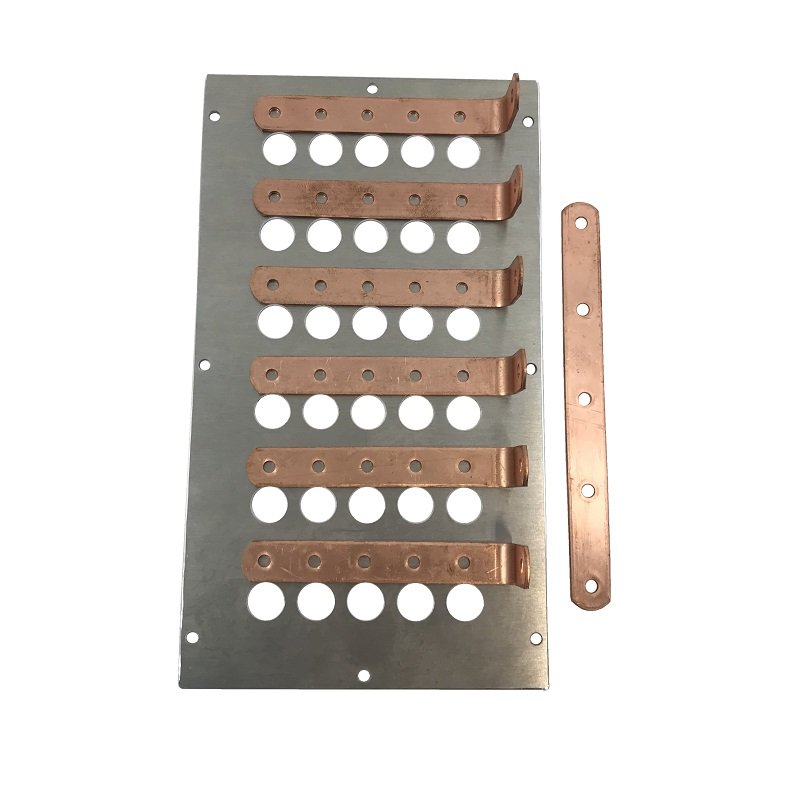

RV14 Circuit Breaker Panel - Steinair Inc.

RV14 Circuit Breaker Panel has 30 holes for our Klixon circuit breakers. RV14 Circuit Breaker Panel Steinair Inc.