georgemohr

Well Known Member

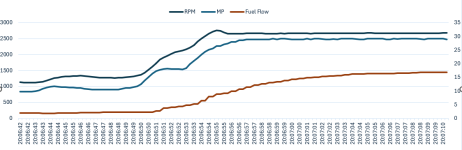

We just performed this test on our 14. Took 2.25 turns in on fine pitch stop for our Hartzell CS prop to get below 2700 static. This is with an IO-390-EXP. I suspect Hartzell is setting these props up for 200HP, and the additional power needs more pitch.