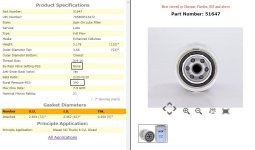

STC applications and the design and compliance data used to receive the STC are generally not public domain. They are considered proprietary to the applicant. However, a FOIA request can be made and if the STC holder has no objection the data can be released. No STC holder generally agrees and it would take a court order.Are STC applications public documents? The STC number appears to be SE02352CH. Responsible office is AIR-7C0: Chicago ACO Branch. Does this group know anyone there?

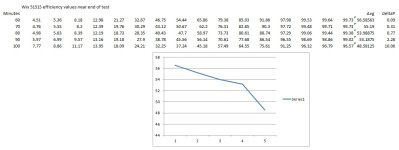

Gary, I'm working with data listing the efficiency of three filters, for 16 different particle sizes recorded at 10 minute intervals. They do not filter better as they load, although some columns spike a bit just prior to termination at 10 psi deltaP. Please see post #11 for an example.

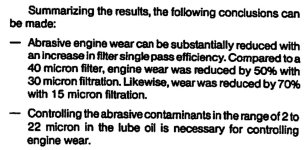

The original Lycoming was certified with a pretty coarse mesh screen filter. They recommended 25 hr oil change intervals. The spin on filter was introduced as an option that moved the recommended oil changes for some operations to 50 hrs.

The new mesh filters have a pretty low standard to meet to show “equal to or better than“ performance than the original.