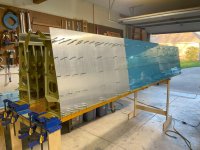

I'm at the point of installing the top skins on my -10 wings. Looking for tips or techniques on how other builders accurately true up the spar and ribs substructure for the prep and riveting of the top wing skins.

I don't want to introduce any twist or bend in the finished product and trying to figure out how accurate I need to be in truing up the spar before putting the skins on?

Using a digital protractor (I have a Wixey), it's easy to make sure there is no twist in the spar, but how straight does it need to be along the length (bow)? Right now there is a small amount of bow between the sawhorses.

Is it essentially self-jigging or do I need to put additional supports and shims in the middle of the span?

Thanks for sharing your experience and how you approached it.

I don't want to introduce any twist or bend in the finished product and trying to figure out how accurate I need to be in truing up the spar before putting the skins on?

Using a digital protractor (I have a Wixey), it's easy to make sure there is no twist in the spar, but how straight does it need to be along the length (bow)? Right now there is a small amount of bow between the sawhorses.

Is it essentially self-jigging or do I need to put additional supports and shims in the middle of the span?

Thanks for sharing your experience and how you approached it.

Attachments

Last edited: