Desert Rat

Well Known Member

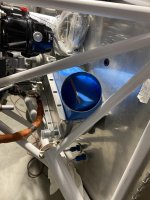

Hey Guys- I'm still noodling around with how to best route oil cooler lines. My firewall mounted oil cooler is about 1/2" too high for this to be easy. i.e. I've got an engine mount tube in the way of the outboard hose port.

I've talked with Tom at TS flightlines. While I'm sure he would build any contraption I come up with, he suggests that it really would be in my best interest to try to avoid having angled fittings on both ends of a hose both for better flow and to minimize manufacturing frustrations with trying to get the clocking right.

I've got a few options, but the cleanest by far would be to just flip the cooler upside down. I'm aware of the potential for trapped air and no way to purge it, but honestly is that really a thing?

I have yet to find anybody who can verify that air in an oil cooler has really ever been an issue. Furthermore, upside down is the standard orientation for the Showplanes remote cooler mount, and those seem to be working out ok for folks?

Option 2 is to run the cooler lines down and forward. I've got them mocked up that way right now and the outboard one comes across the face of the cooler at a distance varying between 1" at the top and 3" at the bottom for about the first 5" of its run.

I'm not worried about the air coming out of the cooler doing anything to a firesleeved hose, but I really don't have any idea of how hot it is there or how it might effect cooling.

Option 2

I've attached pix of the mockup for option #2. As always, comments and critiques are welcome.

Edit- Can someone please tell me why my pictures have started posting sideways and how I fix that?

I've talked with Tom at TS flightlines. While I'm sure he would build any contraption I come up with, he suggests that it really would be in my best interest to try to avoid having angled fittings on both ends of a hose both for better flow and to minimize manufacturing frustrations with trying to get the clocking right.

I've got a few options, but the cleanest by far would be to just flip the cooler upside down. I'm aware of the potential for trapped air and no way to purge it, but honestly is that really a thing?

I have yet to find anybody who can verify that air in an oil cooler has really ever been an issue. Furthermore, upside down is the standard orientation for the Showplanes remote cooler mount, and those seem to be working out ok for folks?

Option 2 is to run the cooler lines down and forward. I've got them mocked up that way right now and the outboard one comes across the face of the cooler at a distance varying between 1" at the top and 3" at the bottom for about the first 5" of its run.

I'm not worried about the air coming out of the cooler doing anything to a firesleeved hose, but I really don't have any idea of how hot it is there or how it might effect cooling.

Option 2

I've attached pix of the mockup for option #2. As always, comments and critiques are welcome.

Edit- Can someone please tell me why my pictures have started posting sideways and how I fix that?

Attachments

Last edited: