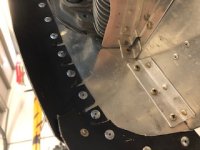

Recent purchase RV6A 0360 carburetor, running high CHT’s.

Critical observation reveals a difficult task of evaluating where air is leaking.

I’ve compared the plans picture to the rubber install and it appears identical.

However I cannot find the upper cowling inner pictures.

There are two distinct areas, the ramp at inlet and then inward of those eyebrows the contour changes.

I’ve been looking for pictures of other cowls on vaf and cannot find postings.

I have the replacement rubber, but I do not want to install it if the contours are incorrect on the cowling.

I could use some help please.

Critical observation reveals a difficult task of evaluating where air is leaking.

I’ve compared the plans picture to the rubber install and it appears identical.

However I cannot find the upper cowling inner pictures.

There are two distinct areas, the ramp at inlet and then inward of those eyebrows the contour changes.

I’ve been looking for pictures of other cowls on vaf and cannot find postings.

I have the replacement rubber, but I do not want to install it if the contours are incorrect on the cowling.

I could use some help please.

Attachments

-

2AE4F2C9-F551-46E2-BEA2-132199F17D15.jpg285.2 KB · Views: 417

2AE4F2C9-F551-46E2-BEA2-132199F17D15.jpg285.2 KB · Views: 417 -

489B89AF-5F8E-4927-BB3B-649D16A1EB87.jpg451.9 KB · Views: 401

489B89AF-5F8E-4927-BB3B-649D16A1EB87.jpg451.9 KB · Views: 401 -

4065D460-85C6-403F-B0AE-05C8714046DB.jpg347.3 KB · Views: 411

4065D460-85C6-403F-B0AE-05C8714046DB.jpg347.3 KB · Views: 411 -

AD62C0DE-BA0B-4DD9-AF75-F21CF11D5EC0.jpg357.7 KB · Views: 432

AD62C0DE-BA0B-4DD9-AF75-F21CF11D5EC0.jpg357.7 KB · Views: 432 -

E1037E06-4A84-4BE5-ADC3-C62DA08E7078.jpg474.9 KB · Views: 392

E1037E06-4A84-4BE5-ADC3-C62DA08E7078.jpg474.9 KB · Views: 392 -

880AB975-BE72-4E65-BE12-37FC20737523.jpg136.2 KB · Views: 339

880AB975-BE72-4E65-BE12-37FC20737523.jpg136.2 KB · Views: 339 -

DD01E216-7E22-41F0-B65B-7C08BE8ED153.jpg347.9 KB · Views: 395

DD01E216-7E22-41F0-B65B-7C08BE8ED153.jpg347.9 KB · Views: 395