bsbarnes10

Active Member

Hi,

I've got some questions about how the stub spar socket (F-1206C) is supposed to fit on to the end of the spar (W-1208B-R & L & W-1207B). Looking at step 8 on page 20iS/U-03 it states:

"File the rear stub spar rounded ends of both wings to closely fit the recessed machined curve of the F-1206C. See Figure 4. The small flat on F-1206C locates the top of the part."

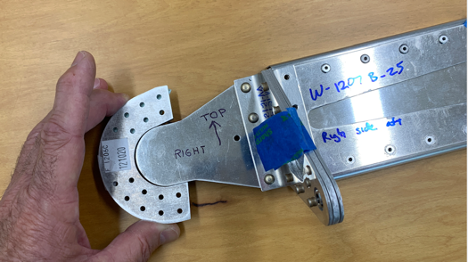

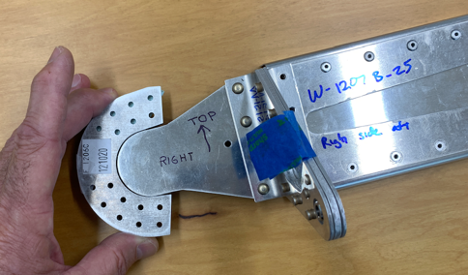

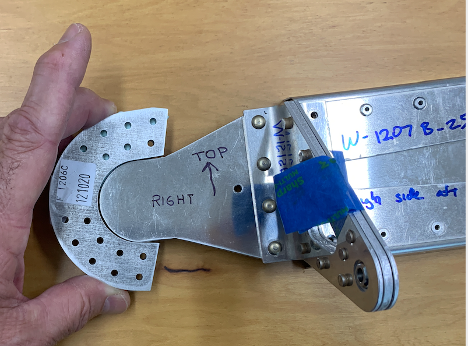

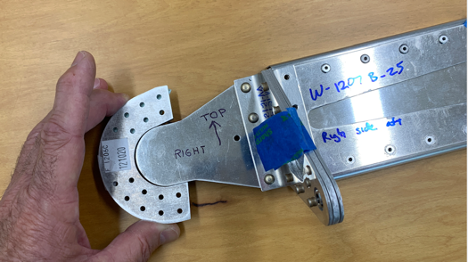

What orientation should F-1206C be "clocked" to when filing the end of the spars? If I had to guess I would think it should be as shown in figure 1, with the flat on the bottom of the spar aligning with the flat on the socket. However, figure 2 & 3 show the socket rotated further and I didn't see anywhere in the plans where it is clearly described which is correct. I could also see how the orientation in figure 3 could make sense.

I did search and find an earlier post on this but the image was broken so I couldn't see what the forum members agreed was correct. Since I don't have a completed airplane handy I can't check and see the orientation of the wings vs. the fuselage socket...

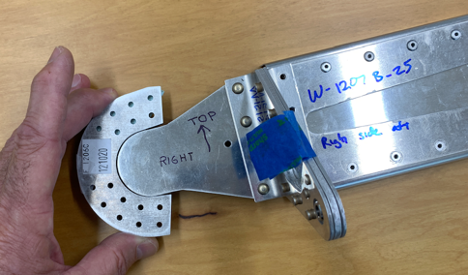

Figure 1 (this is how I think it should be):

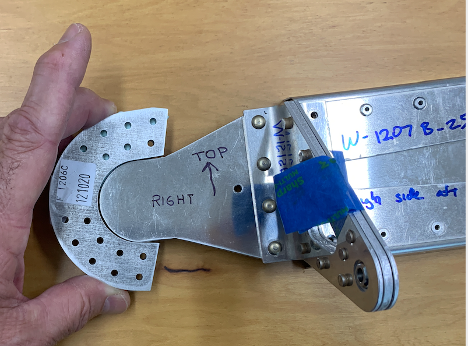

Figure 2 (rotated about midway):

Figure 3: (rotated all the way the other direction):

Any help would be greatly appreciated!

I've got some questions about how the stub spar socket (F-1206C) is supposed to fit on to the end of the spar (W-1208B-R & L & W-1207B). Looking at step 8 on page 20iS/U-03 it states:

"File the rear stub spar rounded ends of both wings to closely fit the recessed machined curve of the F-1206C. See Figure 4. The small flat on F-1206C locates the top of the part."

What orientation should F-1206C be "clocked" to when filing the end of the spars? If I had to guess I would think it should be as shown in figure 1, with the flat on the bottom of the spar aligning with the flat on the socket. However, figure 2 & 3 show the socket rotated further and I didn't see anywhere in the plans where it is clearly described which is correct. I could also see how the orientation in figure 3 could make sense.

I did search and find an earlier post on this but the image was broken so I couldn't see what the forum members agreed was correct. Since I don't have a completed airplane handy I can't check and see the orientation of the wings vs. the fuselage socket...

Figure 1 (this is how I think it should be):

Figure 2 (rotated about midway):

Figure 3: (rotated all the way the other direction):

Any help would be greatly appreciated!