Would like to hear some opinions on what I should do here. I have an RV-4 that was built in 1991 and it appears time when they installed the piano hinge on the top and bottom cowl they put a 2 to 3 inch wide piece of glass under it and used the same epoxy to do a final coat on the inside of the cowl.

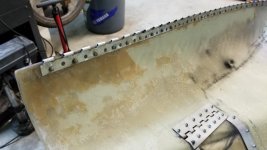

Now 30 years later (it's only flown 280 hours) it seems like there was never a bond or that bond is no longer there. Near the strip of glass it is completely delaminated from the layers below. In the middle of the cowl it looks like little air pockets where the top most layer of epoxy has lifted.

What I've done so far is take a plastic scraper and ran it over things to flake off what is easy to flake off. On the top cowl I went ahead and broke the glass strip near the piano hinge.

Should I just leave it as is for now and keep scraping it off over time or is there a need to sand it all off and put a thin coat of epoxy down? I am not sure if he was using polyester resin or just skipped the step of scuffing before applying epoxy so it would stick.

Now 30 years later (it's only flown 280 hours) it seems like there was never a bond or that bond is no longer there. Near the strip of glass it is completely delaminated from the layers below. In the middle of the cowl it looks like little air pockets where the top most layer of epoxy has lifted.

What I've done so far is take a plastic scraper and ran it over things to flake off what is easy to flake off. On the top cowl I went ahead and broke the glass strip near the piano hinge.

Should I just leave it as is for now and keep scraping it off over time or is there a need to sand it all off and put a thin coat of epoxy down? I am not sure if he was using polyester resin or just skipped the step of scuffing before applying epoxy so it would stick.