There has been lots of discussion and conversation about this.

First, PLEASE install the NAS1804 nuts, not NAS679 nuts. The NAS679 stamp-formed nuts are not sufficient for this application. Many examples of these being found loose. Our tests prove that they don't get loose by turning - they get loose by the nut expanding radially enough under tension that the threads actually leapfrog over to the next thread!

The primary reason for installing the better nuts is strength, but an added benefit is that they have smaller wrenching size, so easier to get a socket on the nut. Since the nuts are taller, it is desirable to buy bolts with longer threads - these are NAS6606 rather than NAS6206. The grip length stays the same. Although I say this is desirable, I don't believe it is strictly necessary. If you insist on have clear threads protrude beyond then nut, then yes, get the NAS6606. But with the NAS6206, there is sufficient thread engagement into the locking area of the nut, but perhaps not enough to protrude beyond the nut. So if you are a stickler for that, you will want the NAS6606.

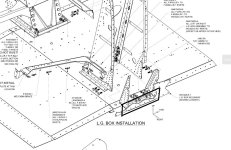

Second, please read the installation instructions for the U-803 bracket. The faces that mate to the bottom of the fuselage are to be filed/ground down so that those faces do not touch when proper torque is applied. If I recall correctly, the prescribed gap is 0.030" or so - but the thing that matters is that they don't touch. This is done to assure that the bracket applies sufficient clamping pressure on the gear leg. If the faces of the bracket were to contact the fuselage prior to reaching proper torque, then adding more bolt torque does not clamp the bracket any tighter onto the gear leg. Unfortunately, this design does mean that the bracket does bend slightly at the proper torque. In a perfect world, it would be better if the faces did touch just at the proper torque, because this would prevent the bracket from bending, but in practice, you have no way to assure that the correct clamping pressure is applied to the gear leg if those faces touch.

Third, it is sort of OK to torque the bolt head rather than the nut, given the near impossibility of torquing the nuts unless the gear tower modification is done. But torquing the bolt head adds a lot of friction from turning the bolt in its hole, so one technique is to measure the friction torque with a torque wrench before drawing the bolt tight. This accounts for the bolt friction, and the locknut friction. Then add this to the specified torque value to get the torque needed to get proper value on the bolt. Even this is conservative, because as the bolt tightens, the friction increases AND the U-803 bracket bends slightly and tends to add more friction from binding on the bolt.

Many RV-8 builders were/are wise to do the gear tower modification to make working in this area quite a bit easier. In hindsight, I do so wish I had done it.

But the good news is that with the good NAS1804 nuts, you will not ever find that they have loosened. I have found that I can check the torque each year by putting a torque wrench on the bolt heads, and the nuts don't turn at the proper torque - I don't need to have a wrench on them.

Hope this helps. If you would like to learn more about this assembly, use the search capability. Look in particular for a very long thread called "breaking news" where we tested various nuts. Any additional questions, feel free to PM me.