To washer or not to washer

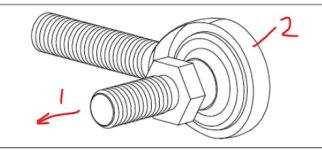

I recall paying a very experienced test pilot to go over my build prior to first flight. I learned a lot from that, but the one thing that seemed out of place was the discussion of the push rod to flap attachment on my RV7.

Unless I missed something, Van's Plans do not call out a washer on that particular Heim Joint. I assume this is due to the reliability of the joint, the need to cut the fuselage for clearance, and the problem generated by a washer hanging up on the aircraft skin.

The inspector shared his desire to see a washer there as personal and not based on any specific knowledge of failures. I can certainly see his point.

However, in that particular assembly I would point to the aluminum tube/pushrod being scored along its inner circumference during threading as being the most likely impeding failure over time. I wouldn't call it likely, or even remotely likely, just much more likely to see fatigue failure in scored aluminum rather than smooth steel.

The inspector's observation bothered me as the consequence of failure weighs heavily on peace of mind, even though the likelihood is so remote at least in my mind to be undefined. How many things can we imagine as going wrong?

I guess I am asking this question again: Does anyone know of a failure mode for these joints other than obvious overload?