Desert Rat

Well Known Member

Well darn.

I bought a second hand almost completed wing kit to start my build journey. Fast forward a couple of years and I did the first temporary install of the wings on my fuselage.

Wings fit good, triangulated easily, incidence and sweep set, drilled/reamed the all important aft spar hole a few thousands undersize for a AN5 bolt. Life is good.

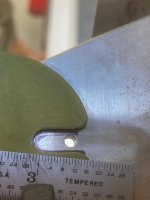

Today I started all the cleanup tasks you do after the wings are on, and very first thing when I started looking at locating the hole for the bolt that goes through the fwd tank attach bracket to the slotted steel flange coming off the fuselage, I realized that the guys I bought the wings from had helpfully pilot drilled a #30 hole in exactly the wrong spot on the starboard tank.

I can't center the bolt hole on this because it's way to far out of the slot for the bolt to give any meaningful support to the nose of the tank, and I can't use it for as a rivet hole for one leg of the nut plate because it's a #30 hole instead of a #40.

This last part is what really sucks because one leg of a k1000-428 nutplate lines up perfectly with it.

As I see it, my options are:

1- to upsize one leg of a nutplate for a #30 rivet, which is iffy because the call out is for a skinny nutplate, so that would put the big hole and little hole uncomfortably close together.

2- to clock the nutplate vertically instead of horizontally and fill the errant hole with a double flush rivet.

3- to pull the tank off, drill out the aluminum angle from the inner end and build a new one without the offending hole, with the pro seal mess and extra time involved.

4- vans suggestion (which they just came back with while I was typing this) fabricate a new bracket and extend the ears out from the fuselage a little bit more.

curious what opinions the collective might have...

I bought a second hand almost completed wing kit to start my build journey. Fast forward a couple of years and I did the first temporary install of the wings on my fuselage.

Wings fit good, triangulated easily, incidence and sweep set, drilled/reamed the all important aft spar hole a few thousands undersize for a AN5 bolt. Life is good.

Today I started all the cleanup tasks you do after the wings are on, and very first thing when I started looking at locating the hole for the bolt that goes through the fwd tank attach bracket to the slotted steel flange coming off the fuselage, I realized that the guys I bought the wings from had helpfully pilot drilled a #30 hole in exactly the wrong spot on the starboard tank.

I can't center the bolt hole on this because it's way to far out of the slot for the bolt to give any meaningful support to the nose of the tank, and I can't use it for as a rivet hole for one leg of the nut plate because it's a #30 hole instead of a #40.

This last part is what really sucks because one leg of a k1000-428 nutplate lines up perfectly with it.

As I see it, my options are:

1- to upsize one leg of a nutplate for a #30 rivet, which is iffy because the call out is for a skinny nutplate, so that would put the big hole and little hole uncomfortably close together.

2- to clock the nutplate vertically instead of horizontally and fill the errant hole with a double flush rivet.

3- to pull the tank off, drill out the aluminum angle from the inner end and build a new one without the offending hole, with the pro seal mess and extra time involved.

4- vans suggestion (which they just came back with while I was typing this) fabricate a new bracket and extend the ears out from the fuselage a little bit more.

curious what opinions the collective might have...