propflipper

Active Member

Hopefully the G3X expert can chime in on this :

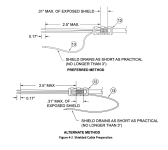

I have seen these beautifully constructed Garmin connectors, done by professionals, with shield terminations exiting solder sleves and neatly looping back to the connector in color coded green wire. They look great, and I am sure they probably work great. But according to the G3X installation manual two wiring crimes have been committed.

On page 24-10 of the G3X touch installation manual it states that " the flat braid should go out the front of the termination toward the connector. It is not permitted to exit the rear of the termination and loop back to the connector."

In a note at the bottom of 24-10 it states" Flat braid as opposed to insulated wire is specified in order to allow continuing air worthiness by allowing for visual inspection of the conductor"

Also, why not just strip about 4" of insulation off, pull the wires though the shield , crimp a lug on it and call it good ?

I would sure hate to hear the inspector tell me to redo the harness.

As always thank you for your feed back.

Tom

I have seen these beautifully constructed Garmin connectors, done by professionals, with shield terminations exiting solder sleves and neatly looping back to the connector in color coded green wire. They look great, and I am sure they probably work great. But according to the G3X installation manual two wiring crimes have been committed.

On page 24-10 of the G3X touch installation manual it states that " the flat braid should go out the front of the termination toward the connector. It is not permitted to exit the rear of the termination and loop back to the connector."

In a note at the bottom of 24-10 it states" Flat braid as opposed to insulated wire is specified in order to allow continuing air worthiness by allowing for visual inspection of the conductor"

Also, why not just strip about 4" of insulation off, pull the wires though the shield , crimp a lug on it and call it good ?

I would sure hate to hear the inspector tell me to redo the harness.

As always thank you for your feed back.

Tom