Michael Seager

Active Member

I took my first RV flight in 1983 so I guess that means I have been flying RVs of all models for at least 38 years. I have helped a lot of people over the years either inspect and test fly or deliver and help check out a lot of people in their planes. I have test flew over 200 brand new RVs and flown more than 400 different airframes of all models of RVs. I have extensive time in all models except the RV-1. Last time I checked my logbook I had well north of 20000 hours in RVs.

I was ask to inspect and deliver an airplane this last weekend. I went and looked at it as I have done many times over the last 38 years. It was a very nice built and finished airplane, professional painted. On occasion I find an airplane that really stands out and this one was not in a good way.

This plane was so touchy to control that it was a handfull to fly even with all my experience. I seldom write on this forum but hopefully this will help some one else have a better flying plane. I have preached this to my students for many years. These two things will improve how your plane flys a lot. This will apply to RV-3 4 6 7 8.

1 Do not cut 6 inches off your control stick. It was designed to be the length that it was shipped in the kit. If you want to cut it down to put on a stick grip make sure you put back to the original length. Nothing I can think of worse than trying to negotiate a strong gusty cross wind with a touchy airplane that has the stick cut off to down between my legs. If you think I'm wrong on this take the steering wheel off your car and replace it with a 4 inch steering wheel and see how it goes. Van has wrote several articles on this and yet I still find lots of planes in the field that have really short cut off sticks. To make things even worse go to high altitude and load up the baggage compartment to make a rear CG and you have a really touchy hard to fly airplane when you cut the stick off. Over the years I used to carry some stick material with me so i could extend the stick back to the proper length before i ferried an airplane.

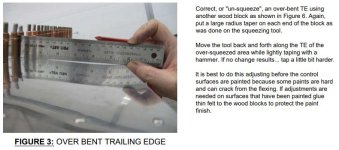

2 Make sure that the trailing edges of the ailerons are squeezed properly. This one very simple to fix item can make your ailerons nasty to fly. I find this a lot when test flying new planes. The trailing edge does not get squeezed enough and it makes this thing called aileron snatch. Aileron snatch makes the aileron very sensitive and unable to center. Give me 10 minutes and a hand seamer and I can fix this. A straight edge and a hand seamer can fix promptly. The particular plane that I delivered this weekend had terrible aileron snatch. Interesting that this plane had flown 700 hours this way and the original owners thought it flew great. I let the new owner fly it before I fixed it and he could believe how much different it flew.

I wonder how many other airplanes out their fly like this one did and could be improved a lot.

Michael Seager

[email protected]

I was ask to inspect and deliver an airplane this last weekend. I went and looked at it as I have done many times over the last 38 years. It was a very nice built and finished airplane, professional painted. On occasion I find an airplane that really stands out and this one was not in a good way.

This plane was so touchy to control that it was a handfull to fly even with all my experience. I seldom write on this forum but hopefully this will help some one else have a better flying plane. I have preached this to my students for many years. These two things will improve how your plane flys a lot. This will apply to RV-3 4 6 7 8.

1 Do not cut 6 inches off your control stick. It was designed to be the length that it was shipped in the kit. If you want to cut it down to put on a stick grip make sure you put back to the original length. Nothing I can think of worse than trying to negotiate a strong gusty cross wind with a touchy airplane that has the stick cut off to down between my legs. If you think I'm wrong on this take the steering wheel off your car and replace it with a 4 inch steering wheel and see how it goes. Van has wrote several articles on this and yet I still find lots of planes in the field that have really short cut off sticks. To make things even worse go to high altitude and load up the baggage compartment to make a rear CG and you have a really touchy hard to fly airplane when you cut the stick off. Over the years I used to carry some stick material with me so i could extend the stick back to the proper length before i ferried an airplane.

2 Make sure that the trailing edges of the ailerons are squeezed properly. This one very simple to fix item can make your ailerons nasty to fly. I find this a lot when test flying new planes. The trailing edge does not get squeezed enough and it makes this thing called aileron snatch. Aileron snatch makes the aileron very sensitive and unable to center. Give me 10 minutes and a hand seamer and I can fix this. A straight edge and a hand seamer can fix promptly. The particular plane that I delivered this weekend had terrible aileron snatch. Interesting that this plane had flown 700 hours this way and the original owners thought it flew great. I let the new owner fly it before I fixed it and he could believe how much different it flew.

I wonder how many other airplanes out their fly like this one did and could be improved a lot.

Michael Seager

[email protected]