Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AX-O's Fastback RV-4

- Thread starter AX-O

- Start date

AX-O

Well Known Member

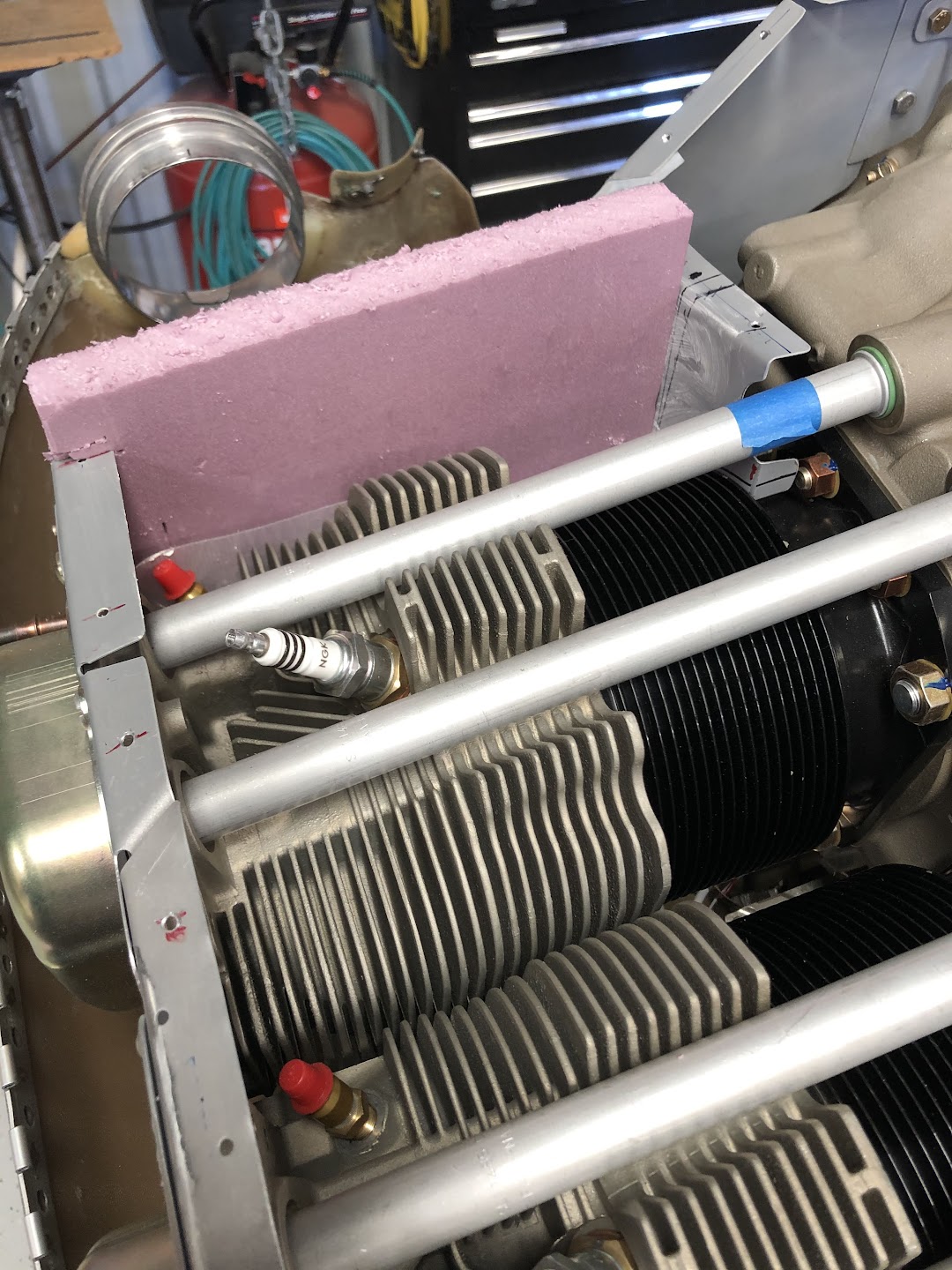

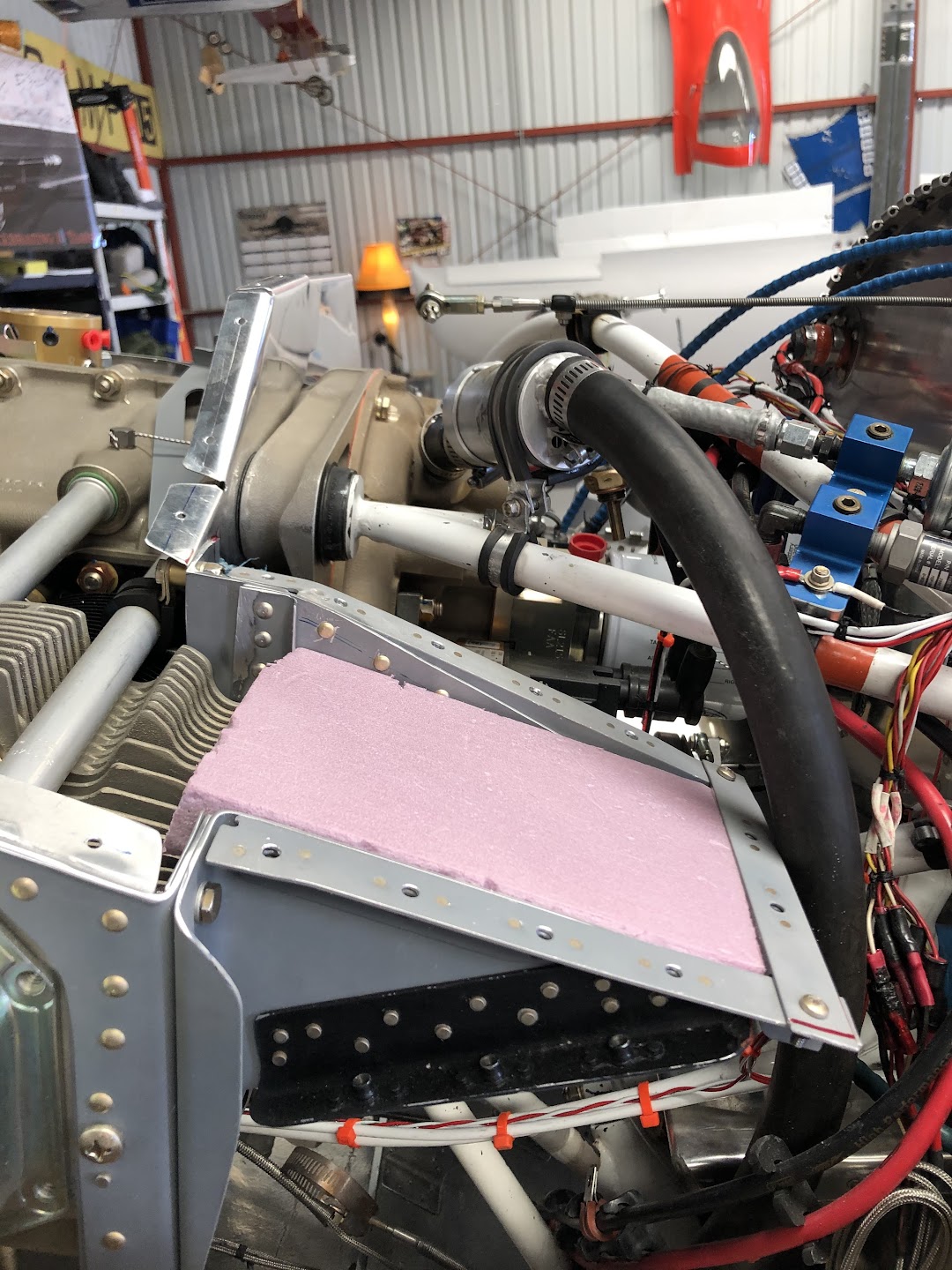

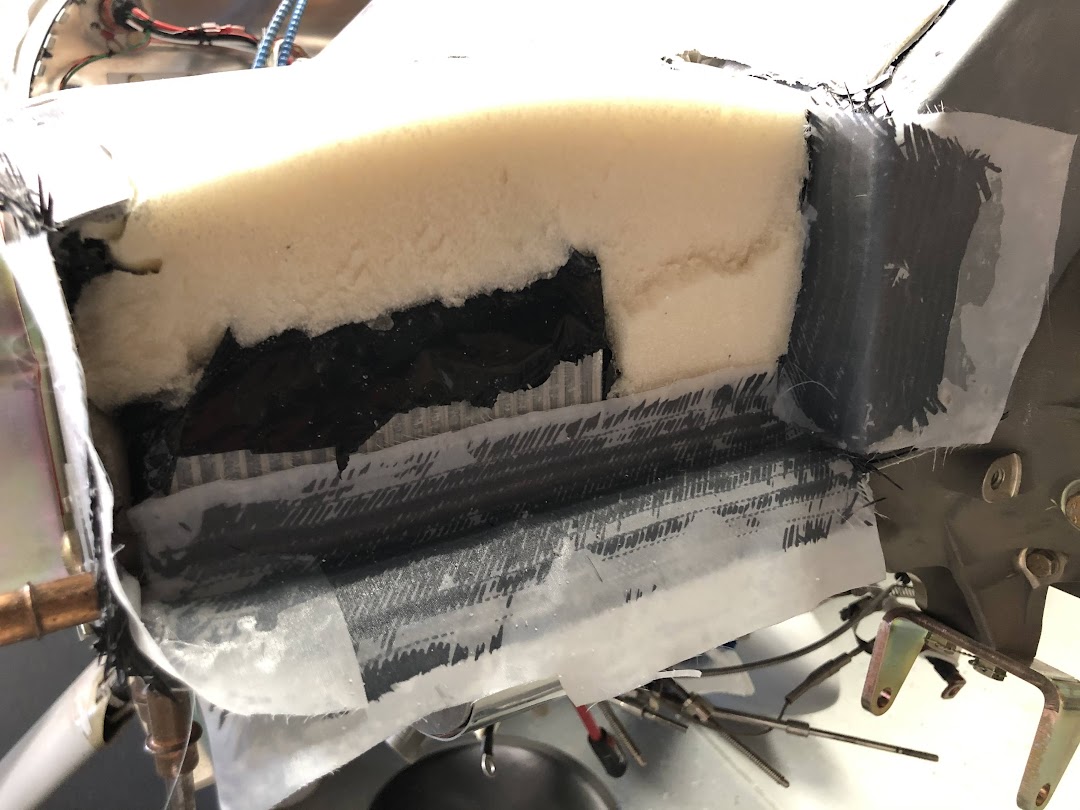

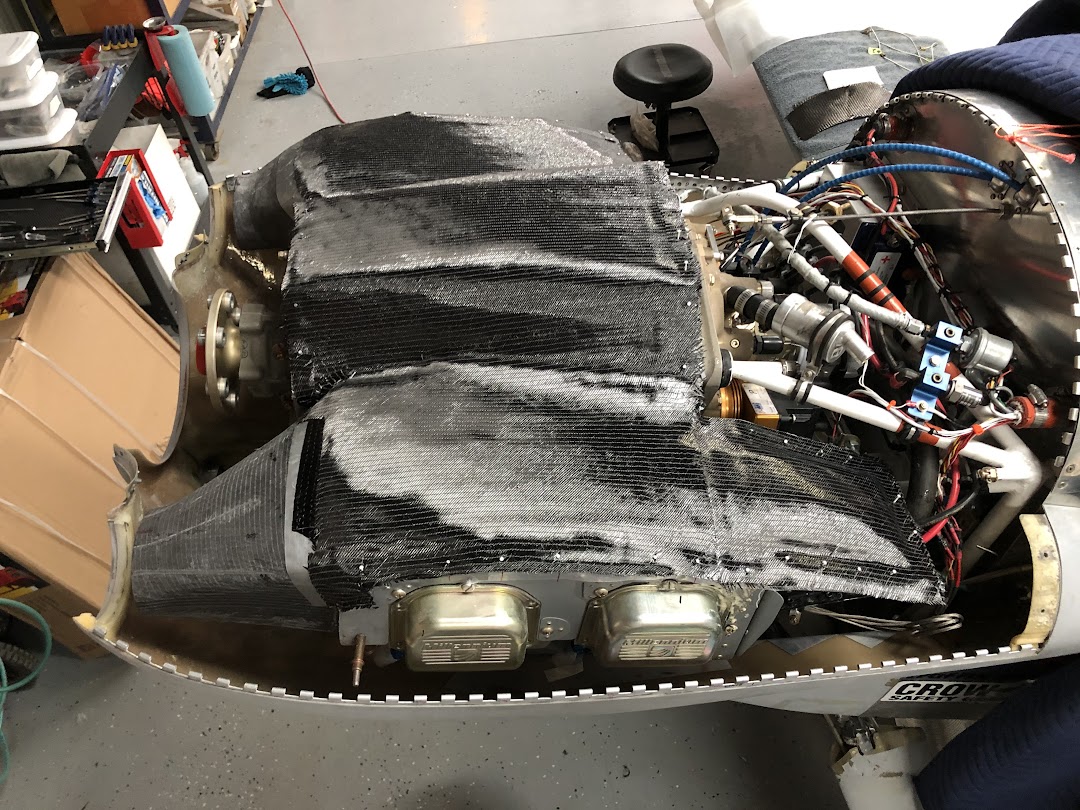

This was one of the scariest thing I have done to my plane. I had nightmares of foam stuck to my engine.

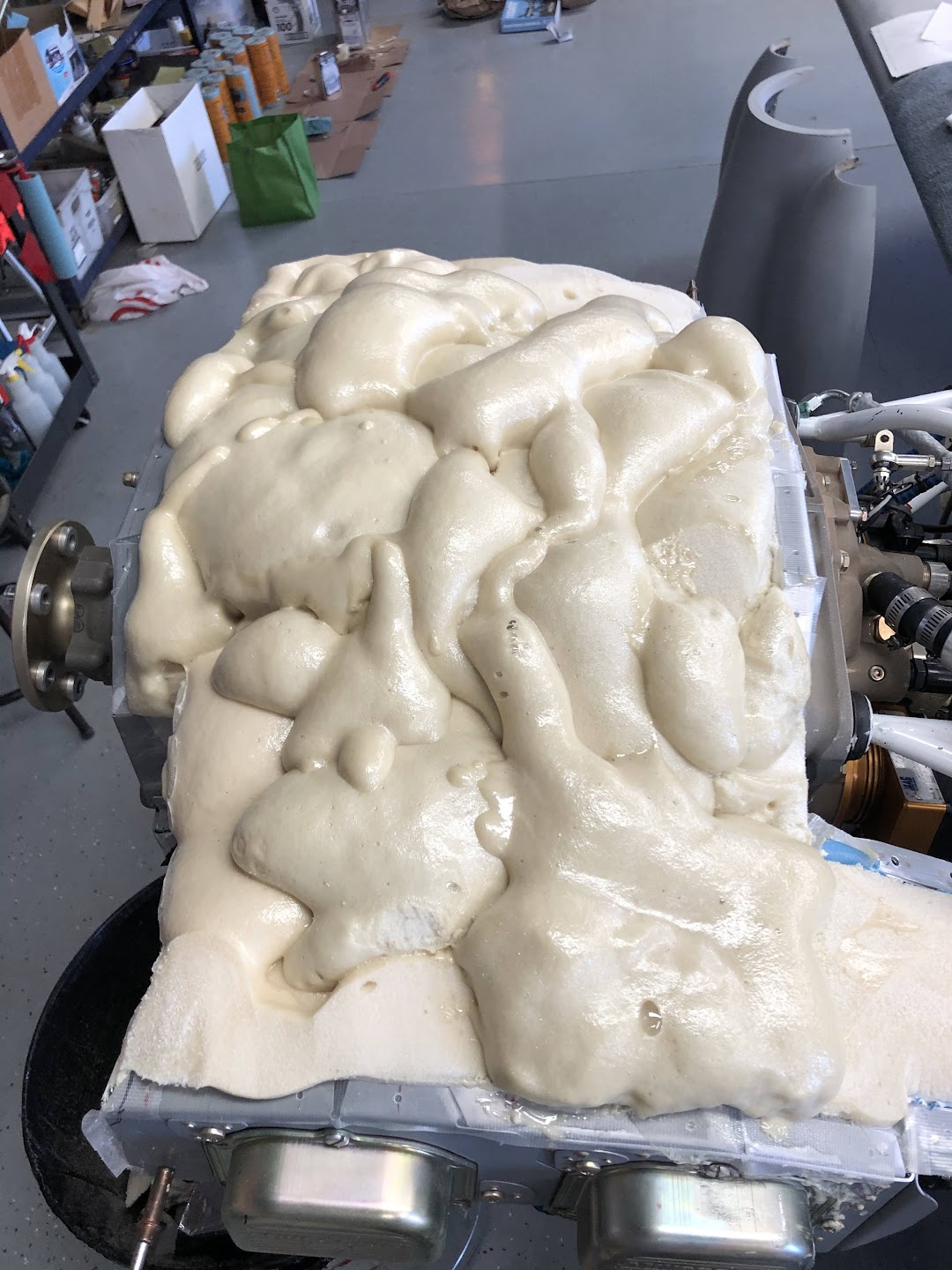

I decided to tape a heavy trash bag to the engine baffles and make a few dams around the engine to keep the foam contained. The foam needed to expand around items (lock in place). I used 2 part pour foam. Learned a trick from a long EZ guy around the airport. Poured the measured content in a zip lock bag. Mixed it, then cut the tip of one of the corners and poured it. Also if you let the foam start to set just a bit before you pour it, the foam becomes easier to control and runs less (sticks to other foam or surfaces).

After sanding through different layers of foam that were made from different pouring times, it became apparent that you want to try to keep the different pouring to a minimum. sanding between the layers became inconsistent.

I decided to tape a heavy trash bag to the engine baffles and make a few dams around the engine to keep the foam contained. The foam needed to expand around items (lock in place). I used 2 part pour foam. Learned a trick from a long EZ guy around the airport. Poured the measured content in a zip lock bag. Mixed it, then cut the tip of one of the corners and poured it. Also if you let the foam start to set just a bit before you pour it, the foam becomes easier to control and runs less (sticks to other foam or surfaces).

After sanding through different layers of foam that were made from different pouring times, it became apparent that you want to try to keep the different pouring to a minimum. sanding between the layers became inconsistent.

Ralph Inkster

Well Known Member

Brings back memories!

I completely foamed Bill Beaton's supercharged engine to fashion its custom cowl. Looked like the Pillsbury Doughboy's plane. Some how I managed to do it without any sticky residue left on the engine components. Sliced it off in upper & lower halfs.

Never again...

I completely foamed Bill Beaton's supercharged engine to fashion its custom cowl. Looked like the Pillsbury Doughboy's plane. Some how I managed to do it without any sticky residue left on the engine components. Sliced it off in upper & lower halfs.

Never again...

AX-O

Well Known Member

After sanding down the foam it was time to make it a smooth as possible. I used fast dry wall putty and sanded it down once it was dry. once that was done, I used one of my favorite trick of using clay to determine how much space is available between parts. In this case between the plenum and the cowling.

Well this is a Problem!!

Well this is a Problem!!

AX-O

Well Known Member

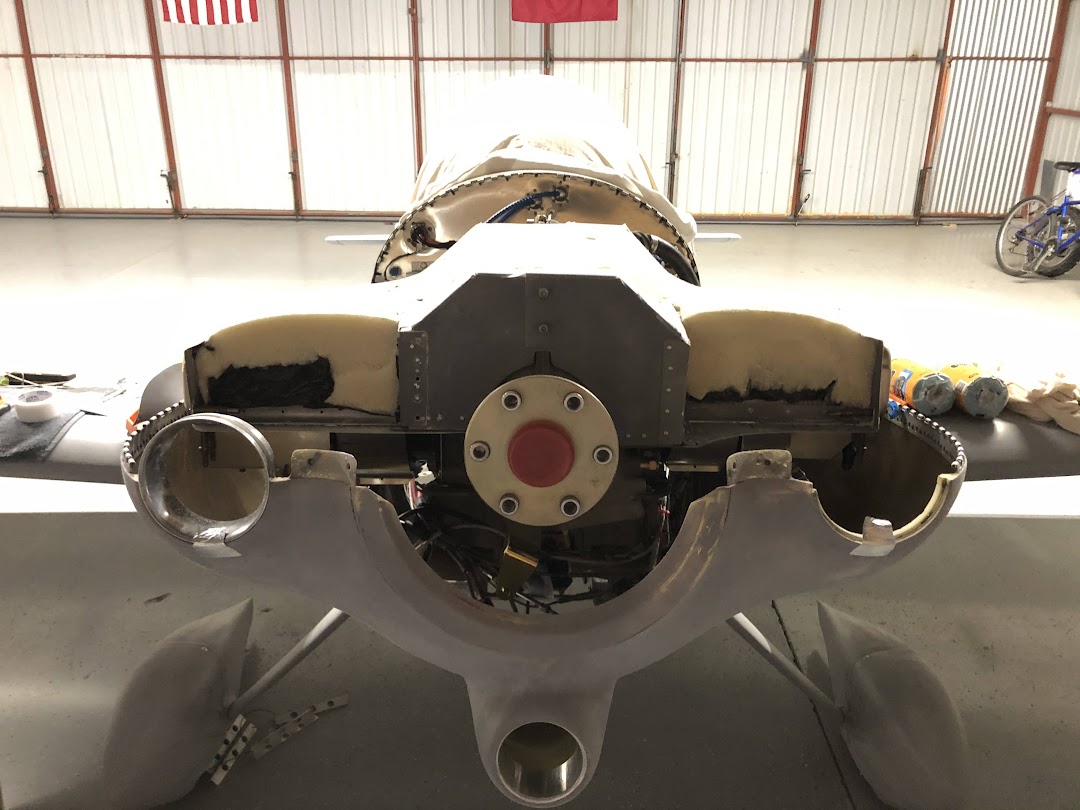

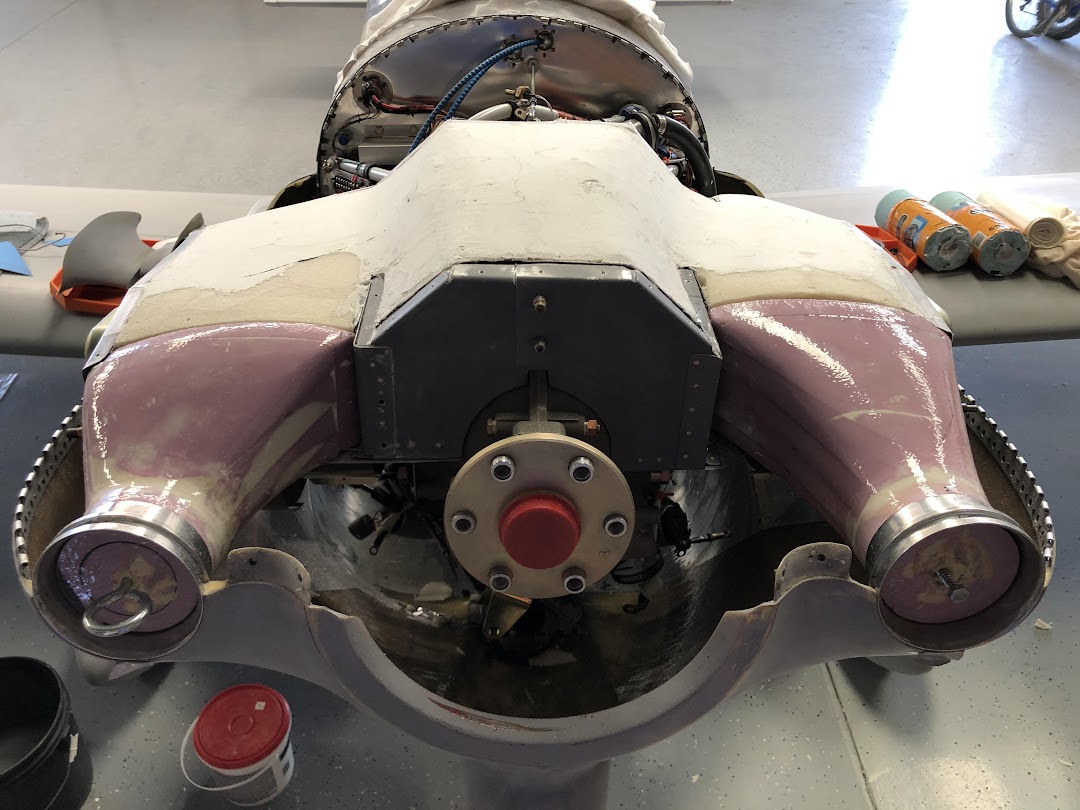

I spent a long time trying to get the intake diffusers to line up right with the inlet rings. I laid a couple of layers of carbon fiber on the baffles to have a good contour of the surfaces. That would allow me to "glue" the already made diffusers in place at the right angles. The peel ply facilitated the process once pulled. I used standard West Systems epoxy with slow hardener. I have had good result with this on the last few plenums.

AX-O

Well Known Member

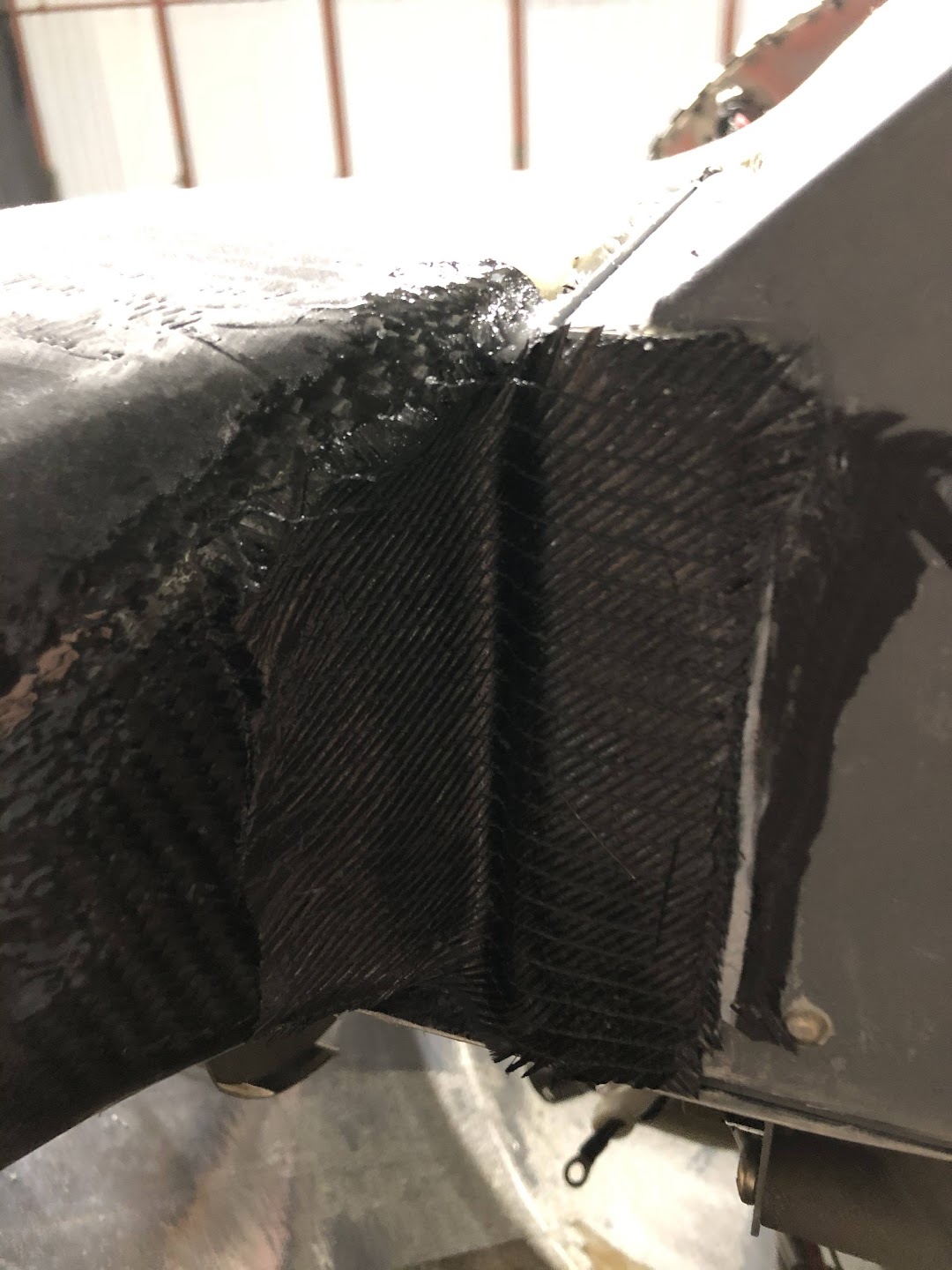

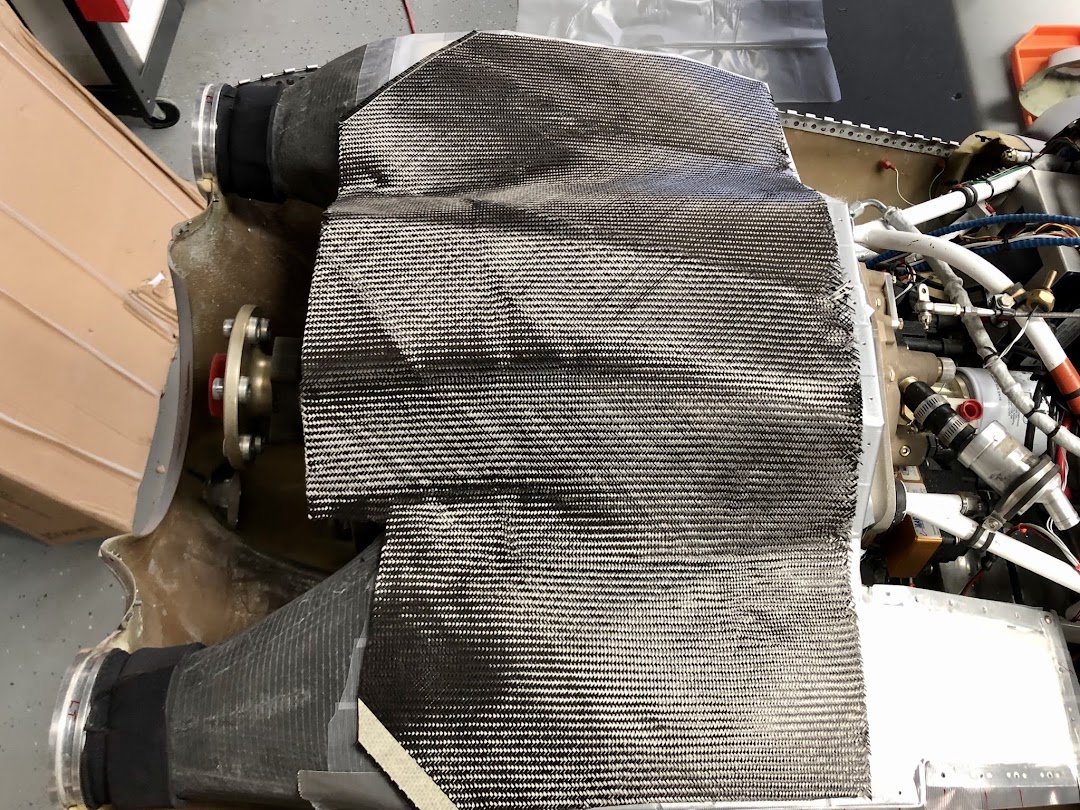

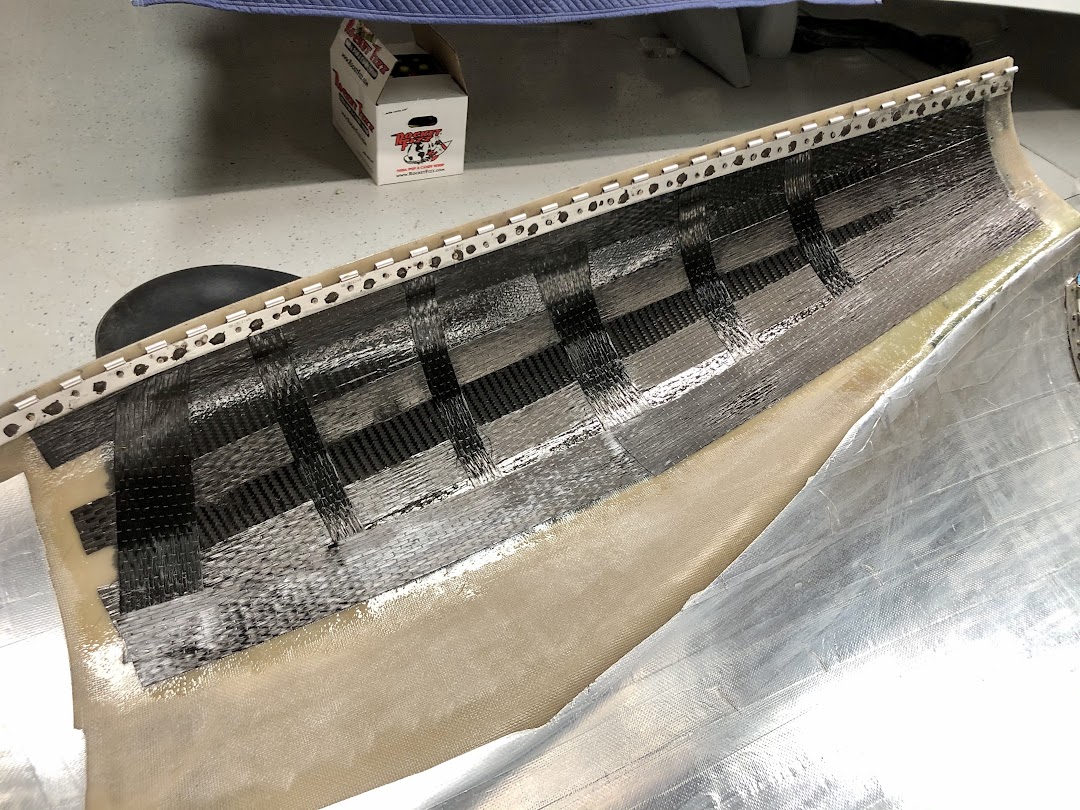

Time to make the plenum. I used left over bi and uni directional carbon fiber from the Formula 1 race plane. In some places I have 3 layers and in some places 4. I purposely put arcs and sharp bends in the plenum design to add rigidity to the part. After the plenum was laid, I inserted nails in the previously drilled locations so I could match drill the parts together after the plenum was cured. I used 2 space heaters and got the temp inside the cowl to 140 deg for at least 8 hrs.

Last edited:

AX-O

Well Known Member

Time to address that dang valve cover that does not fit in the cowl. Started with a small hole that just got bigger and bigger and bigger!!!

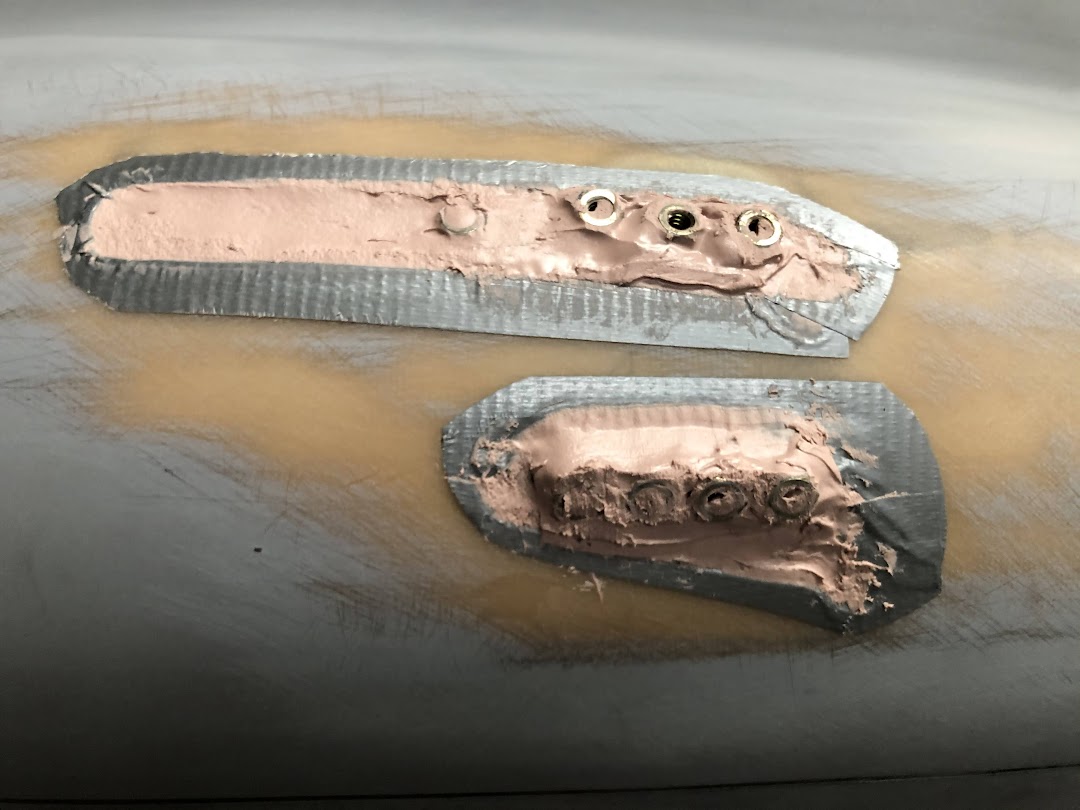

Then I put tape on the vale cover and engine plenum. Glued nuts to a few spots to get a consistent clearance on the final product. Filled in with bondo so nothing would move once I started sanding.

Then used fast dry wall putty to fill in and contour the new cowl shape. This turned into a mold.

Then decided where I was going to cut the cowl once the part was removed from the mold.

Aluminum tape on the cowl so I can lay carbon fiber right on top of it.

Blue tape so I knew exactly where to cut the part. Once the part was off, I just cut the blue tape off the part and the cowl flange matches.

Then I put tape on the vale cover and engine plenum. Glued nuts to a few spots to get a consistent clearance on the final product. Filled in with bondo so nothing would move once I started sanding.

Then used fast dry wall putty to fill in and contour the new cowl shape. This turned into a mold.

Then decided where I was going to cut the cowl once the part was removed from the mold.

Aluminum tape on the cowl so I can lay carbon fiber right on top of it.

Blue tape so I knew exactly where to cut the part. Once the part was off, I just cut the blue tape off the part and the cowl flange matches.

AX-O

Well Known Member

So cowl is asymmetric left to right?

Yes, by the width of a nut.

Toobuilder

Well Known Member

So cowl is asymmetric left to right?

Not speaking for Axel here, but I had to do a similar thing to clear an errant rocker cover on my Rocket. I cut a hole for clearance and just did a flat wrap of manilla folder stock to provide a bump on the left side. Glassed over and faired, its hard to spot unless you are looking for it, but my cowl is certainly asymetric.

Yes, by the width of a nut.

Nicely done. Probably only you can eyeball the difference. Possibly better than making other side too big or way better than local pimple.

Last edited:

cajunwings

Well Known Member

Cowl

Life is Asymetric. Good job!

Don Broussard

RV9 Rebuild in Progress

57 Pacer

Life is Asymetric. Good job!

Don Broussard

RV9 Rebuild in Progress

57 Pacer

AX-O

Well Known Member

Time to make the hole way bigger before we fix the issue.

A few clecos to clock everything in place.

Using the blue tape to mark the cut line.

The new part is not that much wider (shown by the drill bit) but just gives enough room for the valve cover and engine plenum to move.

Time to cut the old stuff out.

Cover the hole with the new part.

Will body work the part later. It is flight worthy.

A few clecos to clock everything in place.

Using the blue tape to mark the cut line.

The new part is not that much wider (shown by the drill bit) but just gives enough room for the valve cover and engine plenum to move.

Time to cut the old stuff out.

Cover the hole with the new part.

Will body work the part later. It is flight worthy.

AX-O

Well Known Member

I don't want to derail this build page with topics outside of my fastback build. Please help me out.

Answer to previous question is that I have been working on the RV-15. you can find info here https://www.kitplanes.com/vans-rv-15-update/

Thanks for the help minimizing thread drift.

Answer to previous question is that I have been working on the RV-15. you can find info here https://www.kitplanes.com/vans-rv-15-update/

Thanks for the help minimizing thread drift.

Looking really nice Axel. Nice work.I forgot to post a pic of the “finished” work. View attachment 55343

AX-O

Well Known Member

not me. Must have been someone else.Axel, I have a vague recollection that when you started this project you intended to fly it solo from the rear seat... Am I mixing you up with someone else, or did the plan change along the way?