LettersFromFlyoverCountry

Well Known Member

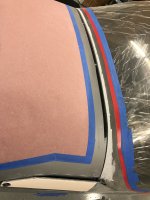

I'm preparing to start on the fiberglass fairing. I've bonded and sanded the foam block. I've cut out the templates and put down two strips of electrical tape.

Here's the thing. The forward edge of the canopy lies a bit below the forward skin and panel at the far left and right edges. If I bridge the fiberglass, there'll be a void.

Here's the thing. The forward edge of the canopy lies a bit below the forward skin and panel at the far left and right edges. If I bridge the fiberglass, there'll be a void.