2NinerFoxtrot

I'm New Here

Hi Everyone,

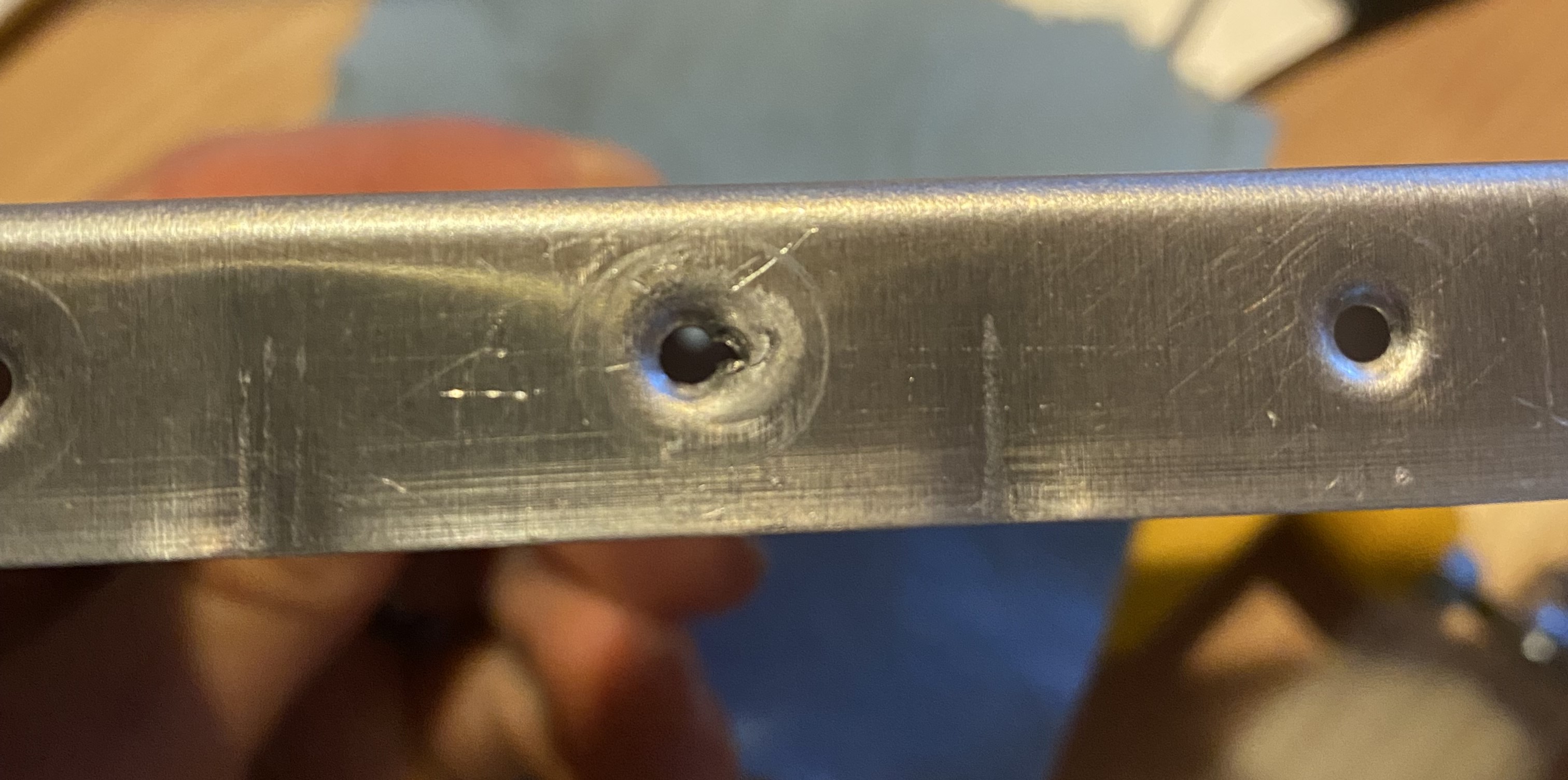

Looks like I might have messed up my first part. A misalignment with my pneumatic dimpler caused me to hit the side of a hole instead of going through the hole properly. I was able to re-align and then properly dimple the hole after the damage had been done, however. This is p/n VS-704 - one of the vertical stabilizer ribs on the 14. Can this part be saved or should I scrap and replace?

Thanks!

Looks like I might have messed up my first part. A misalignment with my pneumatic dimpler caused me to hit the side of a hole instead of going through the hole properly. I was able to re-align and then properly dimple the hole after the damage had been done, however. This is p/n VS-704 - one of the vertical stabilizer ribs on the 14. Can this part be saved or should I scrap and replace?

Thanks!