Flying8

Active Member

I figured I would share my experience from yesterday. I was RV'n around the mountains near Fresno with another RV buddy. After about 45 minutes we decided to RTB. While underneath the charlie shelf for KFAT, I started breathing 100LL fumes. Not just a little odor, but actually eyes watering, nostrile burning fumes. Turned the air vent to my face and to my horror I could not find any relief or fresher air.

After that I completed about 5 seconds of troubleshooting which was basically looking down at the fuel selector as I figured that a line came off or cracked etc... But didn't see any fuel on the floor. I realized there was no time to mess around and turned immediately to Fresno international and told my buddy I needed to declare emergency which he then responded with KFAT's tower freq. Told tower where I was and sprinted to the field. They halted traffic and rolled the fire trucks. The only thoughts were I was either going to quickly suffocate or catch fire. But luckily with RV speed and our location, I landed in less than 5 minutes.

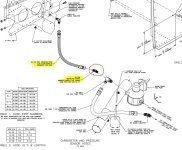

Cracked open the canopy while rolling out, talk about relief! Shut down where the fire trucks were waiting. When I stepped outside I could see 100LL streamed down the left cheek, left gear leg and was draining from the cowl. Limped the plane over to FBO and borrowed some tools. Turned out that the fuel pressure sender line snapped at the collar where the line connects to the pump and was pumping fuel into the cowl, right near the exhaust... Looks like the clamp that secures the sender had shifted and worn out so the fitting on the opposite end of the line was vibrating against the motor mount.

Thats enough excitement for me for a while. I'll go ahead fix this line and ensure everything else is neatly secured in the engine compartment. Might look at installing a fresh air vent on canopy skirt...

Fresno controllers and firefighters were extremely helpful!

After that I completed about 5 seconds of troubleshooting which was basically looking down at the fuel selector as I figured that a line came off or cracked etc... But didn't see any fuel on the floor. I realized there was no time to mess around and turned immediately to Fresno international and told my buddy I needed to declare emergency which he then responded with KFAT's tower freq. Told tower where I was and sprinted to the field. They halted traffic and rolled the fire trucks. The only thoughts were I was either going to quickly suffocate or catch fire. But luckily with RV speed and our location, I landed in less than 5 minutes.

Cracked open the canopy while rolling out, talk about relief! Shut down where the fire trucks were waiting. When I stepped outside I could see 100LL streamed down the left cheek, left gear leg and was draining from the cowl. Limped the plane over to FBO and borrowed some tools. Turned out that the fuel pressure sender line snapped at the collar where the line connects to the pump and was pumping fuel into the cowl, right near the exhaust... Looks like the clamp that secures the sender had shifted and worn out so the fitting on the opposite end of the line was vibrating against the motor mount.

Thats enough excitement for me for a while. I'll go ahead fix this line and ensure everything else is neatly secured in the engine compartment. Might look at installing a fresh air vent on canopy skirt...

Fresno controllers and firefighters were extremely helpful!