So, I plan to glue the canopy of my -14A to the canopy frame with Sikaflex.

The plan is:

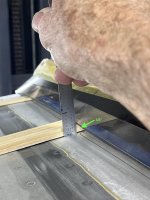

1. Get all surfaces that will see the Sika scuffed good and cleaned

2. Mask the canopy so only areas that will see Sika are exposed.

3. Prepare all the surfaces with Sika Primer and Aktivator

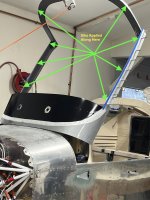

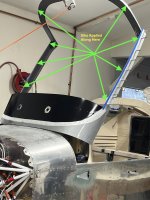

4. Squirt Sika into cavity created by side rails and frame and along frame parallel to rollbar

5. Slip the canopy into position

6. Clamp canopy around the frame forward of the rollbar

7. Cleco the side frame rails tight

8. Allow to set

9. Trim excess that oozes out

Will this work?

The plan is:

1. Get all surfaces that will see the Sika scuffed good and cleaned

2. Mask the canopy so only areas that will see Sika are exposed.

3. Prepare all the surfaces with Sika Primer and Aktivator

4. Squirt Sika into cavity created by side rails and frame and along frame parallel to rollbar

5. Slip the canopy into position

6. Clamp canopy around the frame forward of the rollbar

7. Cleco the side frame rails tight

8. Allow to set

9. Trim excess that oozes out

Will this work?

Last edited: