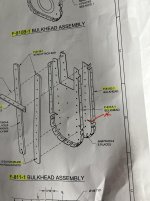

I'm having issues getting the aft most bottom skin (F-828-1 for the RV-8, but I assume all models have a similar part) in place. So far I have spent about 8 hours messing with this thing. It's been the most frustrating part of the build for me so far.

Basically, if I cleco the two aft most bulkheads onto the bottom skin and then slide the skin/bulkhead assembly onto the lower longerons, as called for in the instructions, then I can't get the holes on the bottom skin to line up with the holes in the side skins and lower longerons. If I cleco in the bottom skin first, then I can't get the second aft most bulkhead in place without putting a lot of pressure on the longeron and bulkhead, which I'm really trying to avoid.

The problem is that the skin is made of pretty thick aluminum, so it doesn't want to be shaped. I already tried massaging it with my hands and rolling it like the leading edges of the elevators. The fit has improved but I still can't get it to fit right.

Did any of you have the same problem? What did you do to get these parts to fit without having to stress the parts?

Basically, if I cleco the two aft most bulkheads onto the bottom skin and then slide the skin/bulkhead assembly onto the lower longerons, as called for in the instructions, then I can't get the holes on the bottom skin to line up with the holes in the side skins and lower longerons. If I cleco in the bottom skin first, then I can't get the second aft most bulkhead in place without putting a lot of pressure on the longeron and bulkhead, which I'm really trying to avoid.

The problem is that the skin is made of pretty thick aluminum, so it doesn't want to be shaped. I already tried massaging it with my hands and rolling it like the leading edges of the elevators. The fit has improved but I still can't get it to fit right.

Did any of you have the same problem? What did you do to get these parts to fit without having to stress the parts?