SB-00036 REV 3 published (and new SB kits)

Van's has published SB-00036 REV 3, which requires inspection of the horizontal stabilizer rear spar on RV-3/4/6/7/8/9/10/14 aircraft, as well as new parts and steps necessary to comply with the bulletin should a repair or retrofit need to be performed on RV-3/4/6/7/8 models.

Note that customers who have already ordered SB-00036 kits (whether you've received your kit already or not) will receive the new kit automatically. There is no need to call or place another order. If we have questions about your order, we will reach out to you. The same applies to RV-7 and RV-8 empennage kit owners who received their kits between November 2022 and January 2023.

Also, please note that at this time we are shipping only the SB-00036 kits with non-powder-coated parts.

New kits are available on the Van's online store for the following kits (each link below will display the kits for that model(s). NOTE that we are currently shipping ONLY the non-powder-coated brackets (you will prime with a self-etching primer of your choice). If you order a powder-coated kit, we will not ship a kit to you until the parts are available, and we do not yet know when that will be. If you need to repair an airplane now, order the non-powder-coated kit.

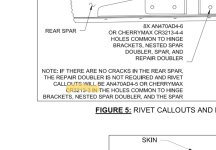

The instructions and drawings in the SB document have been updated to reflect the new parts and changes. We have split the document into sections for each aircraft model, in order to try to keep it as clear as possible for owners.

We started shipping parts today and will continue to ship to people waiting on replacements as well as those with pending orders over the next several days.

What's changed: The parts were revised, and the steps to install the parts changed accordingly. It is important to review the new REV 3 version of the service document, as the prior versions no longer apply and the parts and processes have changed somewhat significantly.

Thank you again for your patience as we have worked though this issue, and as we get kits out the door to those who are waiting for them. We appreciate it very much.

Note that customers who have already ordered SB-00036 kits (whether you've received your kit already or not) will receive the new kit automatically. There is no need to call or place another order. If we have questions about your order, we will reach out to you. The same applies to RV-7 and RV-8 empennage kit owners who received their kits between November 2022 and January 2023.

Also, please note that at this time we are shipping only the SB-00036 kits with non-powder-coated parts.

New kits are available on the Van's online store for the following kits (each link below will display the kits for that model(s). NOTE that we are currently shipping ONLY the non-powder-coated brackets (you will prime with a self-etching primer of your choice). If you order a powder-coated kit, we will not ship a kit to you until the parts are available, and we do not yet know when that will be. If you need to repair an airplane now, order the non-powder-coated kit.

The instructions and drawings in the SB document have been updated to reflect the new parts and changes. We have split the document into sections for each aircraft model, in order to try to keep it as clear as possible for owners.

We started shipping parts today and will continue to ship to people waiting on replacements as well as those with pending orders over the next several days.

What's changed: The parts were revised, and the steps to install the parts changed accordingly. It is important to review the new REV 3 version of the service document, as the prior versions no longer apply and the parts and processes have changed somewhat significantly.

Thank you again for your patience as we have worked though this issue, and as we get kits out the door to those who are waiting for them. We appreciate it very much.

Last edited: