Hey guys,

Saturday a friend helped me mount the WW RV200 prop back on my RV8 with a Mattituck TMX 300 IO360 engine. I had sent the prop out to WW for an OH, and got it back last week.

The friend who helped me was a very experienced pilot and mechanic, but not an A&P.

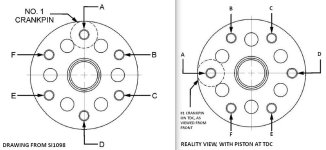

When we were setting up, he commented that my mounting flange did not have the larger locating lug to index the prop, and it looked to him like it could be clocked in any orientation. We mounted it the way it was when I purchased the airplane last month using photos I had taken before it came off. It had run in that orientation for 300+ hours.

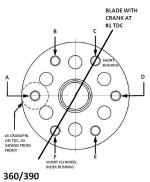

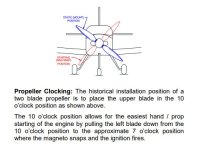

After mounting it hand tight, he told me that the orientation was wrong, as TDC for cyl #1 put the prop about 2/7 o'clock, and he thought it should be 10/5 o'clock, which agrees with what WW says in the manual. We changed it to 10/5 and everything seemed to go on just fine.

On my way home I spoke to another friend of mine who happens to be an A&P, but is a massive "know it all" who regularly speaks as an expert on things he knows nothing about. He was adamant that we had mounted it wrong, and that the mounting flange had 4 drive lugs and 2 flush "indexing" lugs. He's claiming that we had pressed the drive lugs back because of how we mounted it, and the propeller was sure to go into harmonic vibration and fail. He even knew specifically where it would fail, telling me 2" would come off of each tip. Mind you, he has never seen my airplane, or even photos of this setup, and he only works on Mooneys.

So my question: Is there any validity to this, and if so, is there a way I can check on this with the prop mounted? I can provide photos in a couple hours when I get to the hangar.

I'm perfectly willing to pull it back off if I did it wrong.

TIA

Saturday a friend helped me mount the WW RV200 prop back on my RV8 with a Mattituck TMX 300 IO360 engine. I had sent the prop out to WW for an OH, and got it back last week.

The friend who helped me was a very experienced pilot and mechanic, but not an A&P.

When we were setting up, he commented that my mounting flange did not have the larger locating lug to index the prop, and it looked to him like it could be clocked in any orientation. We mounted it the way it was when I purchased the airplane last month using photos I had taken before it came off. It had run in that orientation for 300+ hours.

After mounting it hand tight, he told me that the orientation was wrong, as TDC for cyl #1 put the prop about 2/7 o'clock, and he thought it should be 10/5 o'clock, which agrees with what WW says in the manual. We changed it to 10/5 and everything seemed to go on just fine.

On my way home I spoke to another friend of mine who happens to be an A&P, but is a massive "know it all" who regularly speaks as an expert on things he knows nothing about. He was adamant that we had mounted it wrong, and that the mounting flange had 4 drive lugs and 2 flush "indexing" lugs. He's claiming that we had pressed the drive lugs back because of how we mounted it, and the propeller was sure to go into harmonic vibration and fail. He even knew specifically where it would fail, telling me 2" would come off of each tip. Mind you, he has never seen my airplane, or even photos of this setup, and he only works on Mooneys.

So my question: Is there any validity to this, and if so, is there a way I can check on this with the prop mounted? I can provide photos in a couple hours when I get to the hangar.

I'm perfectly willing to pull it back off if I did it wrong.

TIA

Last edited: