I noticed recently that my right wheel pant had a small amount of fore/aft rotation movement, in disassembling the wheel/brake I found that the brake flange that is bolted to the axle has a very small amount of movement which is amplified by the length of the wheel pant.

It looks like the allen head bolt is moving with the flange suggesting the hole through the axle maybe wallered out (or the bolt is worn).

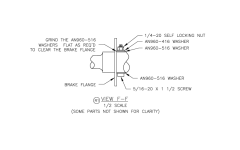

Anyone come across this and have a fix? I plan to fully remove the flange to check and I believe (according to the drawing) the allen bolt is 5/16, is it possible to ream the hole to the next size (3/8) without taking the entire gear leg apart and off the plane (I have a set of chuck reamers).

RV-7 650 hours.

Thanks

Figs

It looks like the allen head bolt is moving with the flange suggesting the hole through the axle maybe wallered out (or the bolt is worn).

Anyone come across this and have a fix? I plan to fully remove the flange to check and I believe (according to the drawing) the allen bolt is 5/16, is it possible to ream the hole to the next size (3/8) without taking the entire gear leg apart and off the plane (I have a set of chuck reamers).

RV-7 650 hours.

Thanks

Figs