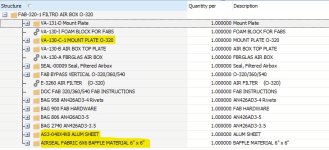

A new version of the Filtered Air Box (FAB) kits will be available to order starting this Thursday on the Van's web store. The FAB kits have now been reduced to two available kits. The carb mount plates were the main difference between the original versions of these kits, and we are now producing the two most common plates. For all others, we are supplying a blank mount plate and the cutout templates are at the back of the instructions.

REASON FOR REVISION:

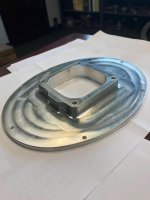

The carburetor is not located on the centerline of the aircraft and so the Filtered Air Box (FAB) must be offset to line up with the lower inlet and not rub against the cowling. The available movement on the original kits was small and to correct this, the mounting plate for the FAB that attaches to the carburetor has been modified to shift the internal cutout to increase the available movement of the FAB.

Additionally, the carb heat door causes wear since there is metal-to-metal contact between the door and the “banjo” of the FAB. The hinge for the carb heat door can wear and become loose or fail. To correct this, the hinge has been replaced with baffle material that is then sandwiched by the carb heat door. The hinge is now made from a flexible material that is less prone to wear and provides a stiffer connection. This baffle material is also now the part of the carb heat door resting against the “banjo” of the FAB, which reduces wear since there is no longer metal-to-metal contact.

REVISION DESCRIPTION / NEW DOCUMENTATION:

FAB 320-360-540 Air Box Rev 0: Document updated to include shifted carb mount plate, updated seal material, and updated carb heat door. Document reformatted and instructions added or rephrased to be clearer and more complete.

The carburetor is not located on the centerline of the aircraft and so the Filtered Air Box (FAB) must be offset to line up with the lower inlet and not rub against the cowling. The available movement on the original kits was small and to correct this, the mounting plate for the FAB that attaches to the carburetor has been modified to shift the internal cutout to increase the available movement of the FAB.

Additionally, the carb heat door causes wear since there is metal-to-metal contact between the door and the “banjo” of the FAB. The hinge for the carb heat door can wear and become loose or fail. To correct this, the hinge has been replaced with baffle material that is then sandwiched by the carb heat door. The hinge is now made from a flexible material that is less prone to wear and provides a stiffer connection. This baffle material is also now the part of the carb heat door resting against the “banjo” of the FAB, which reduces wear since there is no longer metal-to-metal contact.

REVISION DESCRIPTION / NEW DOCUMENTATION:

FAB 320-360-540 Air Box Rev 0: Document updated to include shifted carb mount plate, updated seal material, and updated carb heat door. Document reformatted and instructions added or rephrased to be clearer and more complete.