I've gotten a few inquiries on the methods / materials that I used to polish my RV-9A that's currently posted for sale here.

First off, I didn't start out as an expert, nor do I think of myself as one now that I've polished one aircraft. However, I did contact the experts at NuVite, and following their advice and a fair amount of practice I think I've mostly figured it out, and I'm seeing good results. Your milage may vary.

Equipment

Meguiar's Professional DA Polisher 110-127V - ACS P/N 09-04525 - $309.00

Meguiar's DA Backing Plate, 6" - ACS P/N 09-04533 - $21.55

Cyclo Orbital Polisher Model #5 - ACS P/N 09-35715 - $365

Polish

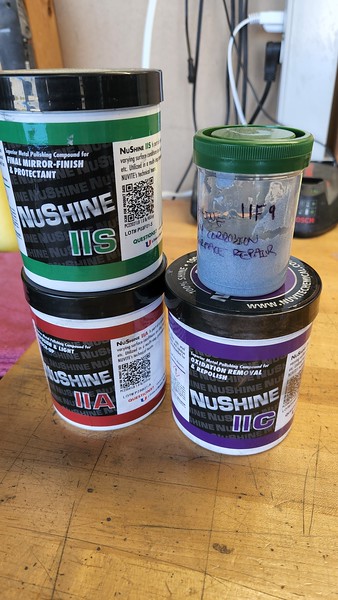

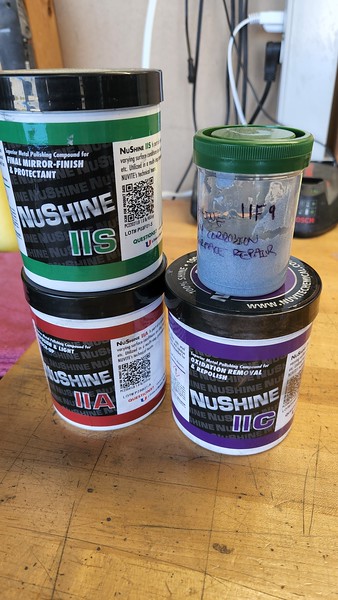

NuVite NuShine IIF9 Heavy Corrosion & Surface Repair - ACS P/N 09-02086 - $47.00

NuVite NuShine IIC Oxidation Removal & Repolish - ACS P/N 09-00587 - $47.00

NuVite NuShine IIA Repolish & Light Touch-Up - ACS P/N 09-02088 - $47.00

NuVite Nushine IIS Final Mirror-Finish & Protectant - ACS P/N 09-00578 - $47.00

Consumables

NuShine Flannel Polishing Cloths, 10-Pak - ACS P/N 09-05346 - $76.75

Meguiar's Rotary Foam Finishing Pad, 7" - ACS P/N 09-04524 - $16.95

Meguiar's Rotary Foam Cutting Pad, 7" - ACS P/N 09-04523 - $17.50

Microfiber Towels - the least expensive source for these is Costco, Sam's, Amazon, etc.

Acetone

Methods

1.) Figure out where you want to begin. I found it easiest to work with one "grit" of polish at a time, working through all areas of the aircraft before moving on to the next stage.

2.) Match the polish and pads as follows:

IIF9 polish and red cutting pad - DA polisher

IIC polish and red cutting pad - DA polisher

IIA polish and black finishing pad - DA polisher

IIS polish and flannel cloth - Cyclo polisher

3.) I found I had best results when I used pads that were dedicated to each of the different polish grits.

4.) Very careful masking is a big part of the job.

5.) Use polish sparingly. Carefully touch the pad of your finger onto the top of the polish (in the can). If the "circle" of polish transferred onto your finger is larger than a 1/4" in diameter you probably have too much. DO NOT wipe or smear the polish onto the aluminum as the grit will leave scratches. Instead, gently dab the polish onto the aluminum with small dots (about 10-12) evenly spaced onto the material.

6.) I always had best luck when bringing the "in-motion" polishing head to the material. To start I somewhat quickly move the polisher pad quickly over the whole section to evenly distribute the polish. Next slowly move the polisher back & forth, or up & down, or both to polish the surface. If you didn't apply too much polish, you'll notice it appears to disperse to the point that you can't really see it any longer after a couple passes. If you have to work the area repeatedly and the polish doesn't disperse quickly you likely used too much polish. When this happens wipe the area down with a microfiber towel soaked with acetone, don't add more polish, and continue to polish using the same pad. Another down side to using too much polish is that the pads get loaded up too quickly and need to be replaced.

7.) Polish in sections of about 2' x 3' (uses rivet lines as boundaries), and when moving to the next section overlap your boundaries by 6" x 12".

8.) Before moving to the next grit thoroughly clean the aluminum with a microfiber cloth soaked with acetone. Pay careful attention to seams, rivet lines, screw heads, etc. You're going to go through a lot of acetone and microfiber towels, don't skimp, you'll notice that dirty towels will leave scratches from the grit embedded in the towel, especially during the final two stages.

9.) I find polishing in general to be a very slippery slope, and a hazardous environment to anyone possessing OCD tendencies. I remember someone on VAF once describing it as more of a way-of-life than simply a method of treating/finishing aluminum, and there's definitely a lot of truth to that!

First off, I didn't start out as an expert, nor do I think of myself as one now that I've polished one aircraft. However, I did contact the experts at NuVite, and following their advice and a fair amount of practice I think I've mostly figured it out, and I'm seeing good results. Your milage may vary.

Equipment

Meguiar's Professional DA Polisher 110-127V - ACS P/N 09-04525 - $309.00

Meguiar's DA Backing Plate, 6" - ACS P/N 09-04533 - $21.55

Cyclo Orbital Polisher Model #5 - ACS P/N 09-35715 - $365

Polish

NuVite NuShine IIF9 Heavy Corrosion & Surface Repair - ACS P/N 09-02086 - $47.00

NuVite NuShine IIC Oxidation Removal & Repolish - ACS P/N 09-00587 - $47.00

NuVite NuShine IIA Repolish & Light Touch-Up - ACS P/N 09-02088 - $47.00

NuVite Nushine IIS Final Mirror-Finish & Protectant - ACS P/N 09-00578 - $47.00

Consumables

NuShine Flannel Polishing Cloths, 10-Pak - ACS P/N 09-05346 - $76.75

Meguiar's Rotary Foam Finishing Pad, 7" - ACS P/N 09-04524 - $16.95

Meguiar's Rotary Foam Cutting Pad, 7" - ACS P/N 09-04523 - $17.50

Microfiber Towels - the least expensive source for these is Costco, Sam's, Amazon, etc.

Acetone

Methods

1.) Figure out where you want to begin. I found it easiest to work with one "grit" of polish at a time, working through all areas of the aircraft before moving on to the next stage.

2.) Match the polish and pads as follows:

IIF9 polish and red cutting pad - DA polisher

IIC polish and red cutting pad - DA polisher

IIA polish and black finishing pad - DA polisher

IIS polish and flannel cloth - Cyclo polisher

3.) I found I had best results when I used pads that were dedicated to each of the different polish grits.

4.) Very careful masking is a big part of the job.

5.) Use polish sparingly. Carefully touch the pad of your finger onto the top of the polish (in the can). If the "circle" of polish transferred onto your finger is larger than a 1/4" in diameter you probably have too much. DO NOT wipe or smear the polish onto the aluminum as the grit will leave scratches. Instead, gently dab the polish onto the aluminum with small dots (about 10-12) evenly spaced onto the material.

6.) I always had best luck when bringing the "in-motion" polishing head to the material. To start I somewhat quickly move the polisher pad quickly over the whole section to evenly distribute the polish. Next slowly move the polisher back & forth, or up & down, or both to polish the surface. If you didn't apply too much polish, you'll notice it appears to disperse to the point that you can't really see it any longer after a couple passes. If you have to work the area repeatedly and the polish doesn't disperse quickly you likely used too much polish. When this happens wipe the area down with a microfiber towel soaked with acetone, don't add more polish, and continue to polish using the same pad. Another down side to using too much polish is that the pads get loaded up too quickly and need to be replaced.

7.) Polish in sections of about 2' x 3' (uses rivet lines as boundaries), and when moving to the next section overlap your boundaries by 6" x 12".

8.) Before moving to the next grit thoroughly clean the aluminum with a microfiber cloth soaked with acetone. Pay careful attention to seams, rivet lines, screw heads, etc. You're going to go through a lot of acetone and microfiber towels, don't skimp, you'll notice that dirty towels will leave scratches from the grit embedded in the towel, especially during the final two stages.

9.) I find polishing in general to be a very slippery slope, and a hazardous environment to anyone possessing OCD tendencies. I remember someone on VAF once describing it as more of a way-of-life than simply a method of treating/finishing aluminum, and there's definitely a lot of truth to that!

Last edited: