I've seen other builders post pictures of the various ways they handled the plumbing connections for their GAP 26 pitot tube / AOA probe, but I've never seen photos of this exact method, so I thought I'd share in case it helps someone else.

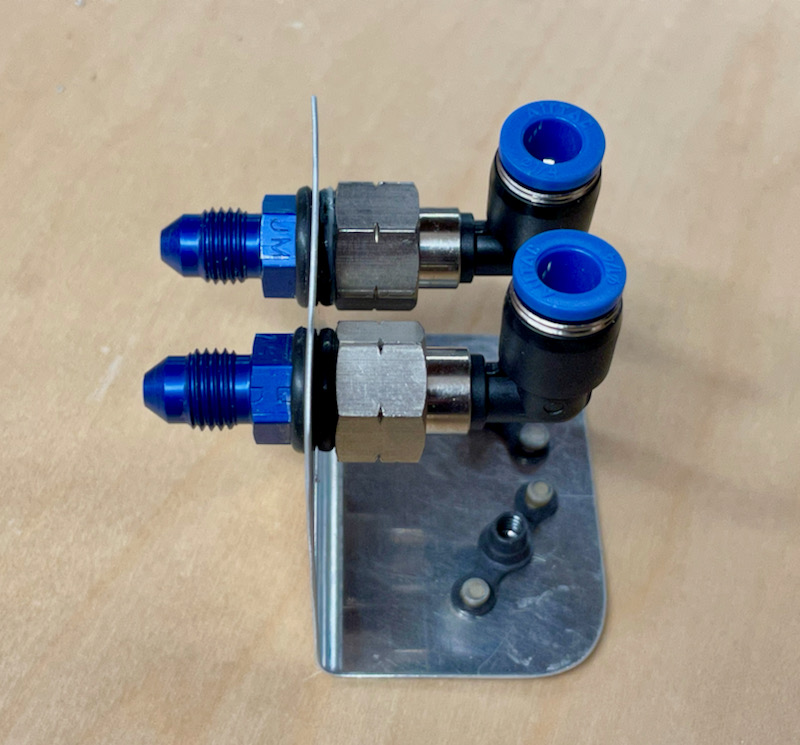

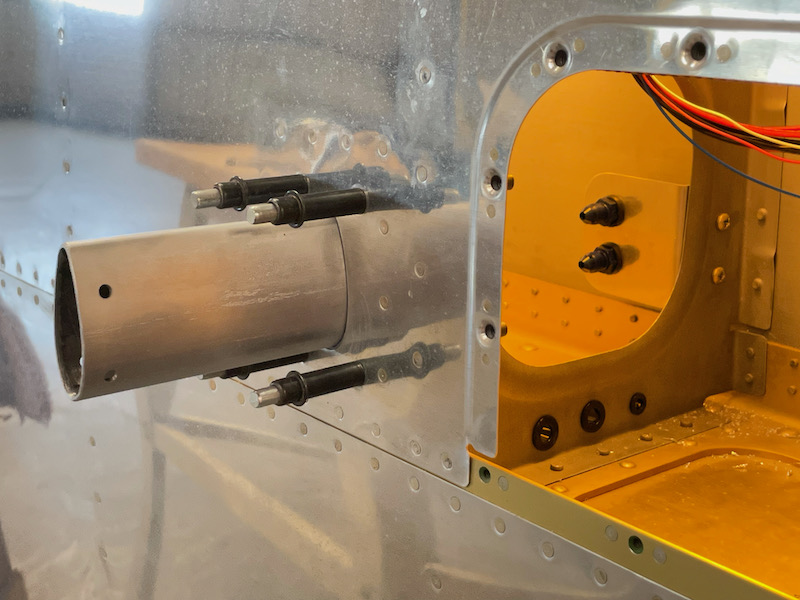

I made this little bracket, which holds a pair of AN816-3D nipples connected to some 90-degree 1/4" push-to-connect air fittings that have female NPT threads:

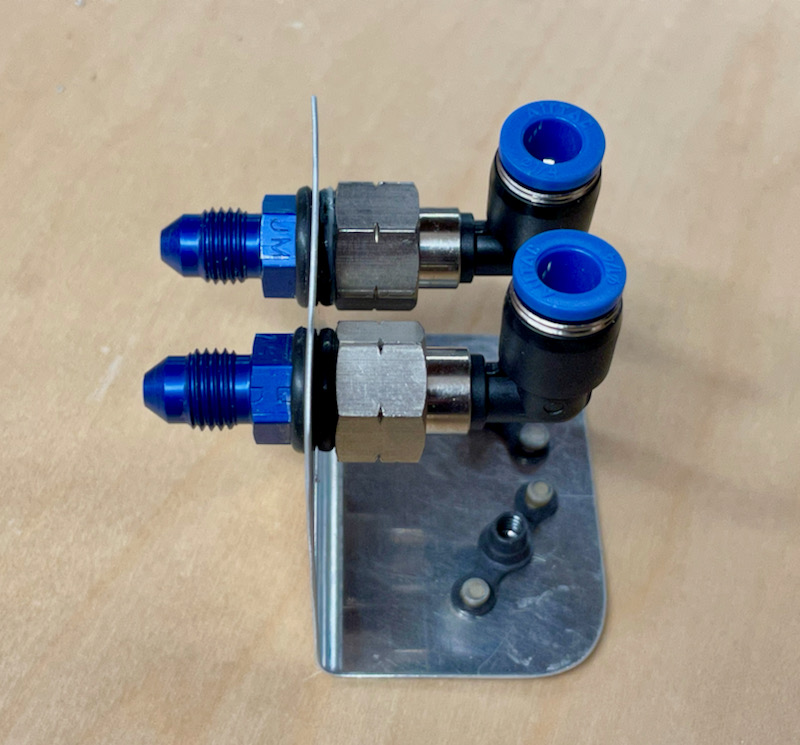

I sandwiched the bracket between the plumbing components using rubber O-rings to create a bulkhead-fitting effect:

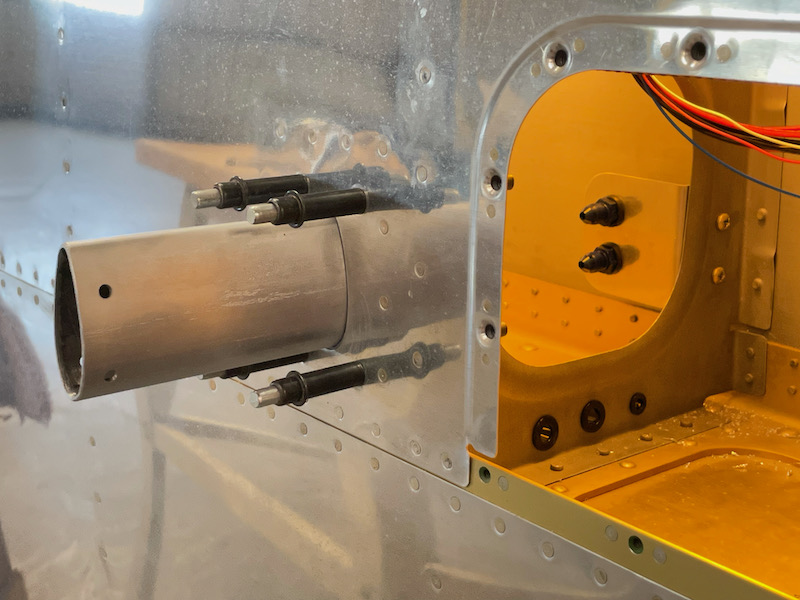

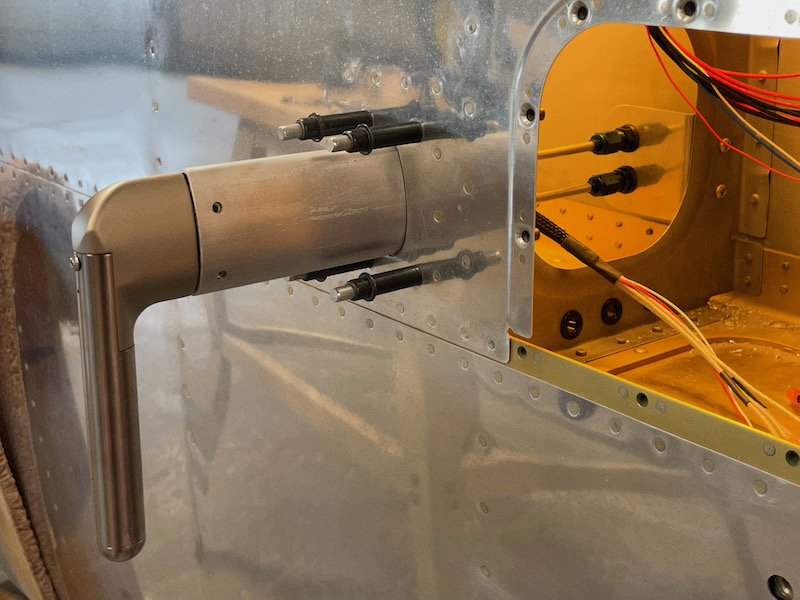

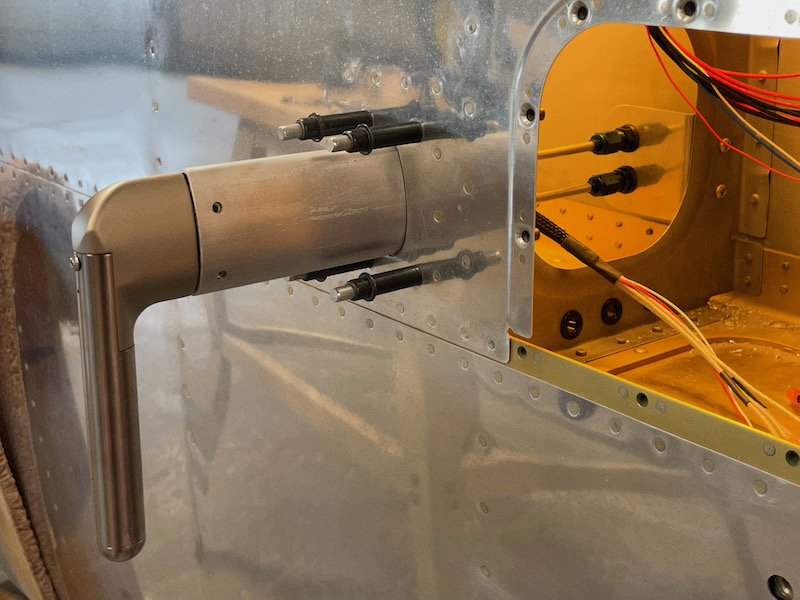

The bracket attaches to the top of a wing rib. The air fittings are on top, with about 1/4" of clearance to the top skin:

The aluminum tubes from the pitot run straight to the bracket fittings, no complicated bending required. The 90-degree fittings face towards the wingtip, and the 1/4" nylon hose will do a gentle 180 from there and then pass through the snap bushings at the front of the rib:

With this method I ended up with almost 9" of tubing coming out of the pitot (8" is the minimum length specified by the manufacturer).

Not sure if this will work in an RV-9 which I think has a skinnier airfoil, but in my RV-7 it worked like a charm and was way easier than trying to bend the tubes but still allow them to pass through the pitot mast.

I made this little bracket, which holds a pair of AN816-3D nipples connected to some 90-degree 1/4" push-to-connect air fittings that have female NPT threads:

I sandwiched the bracket between the plumbing components using rubber O-rings to create a bulkhead-fitting effect:

The bracket attaches to the top of a wing rib. The air fittings are on top, with about 1/4" of clearance to the top skin:

The aluminum tubes from the pitot run straight to the bracket fittings, no complicated bending required. The 90-degree fittings face towards the wingtip, and the 1/4" nylon hose will do a gentle 180 from there and then pass through the snap bushings at the front of the rib:

With this method I ended up with almost 9" of tubing coming out of the pitot (8" is the minimum length specified by the manufacturer).

Not sure if this will work in an RV-9 which I think has a skinnier airfoil, but in my RV-7 it worked like a charm and was way easier than trying to bend the tubes but still allow them to pass through the pitot mast.

Last edited: