Hi!

Just wondering what sort of gap I should be looking for between the lower empennage gap covers (under the HS). I assume 1/16? would be ok since that?s the minimum gap around the elevator horns?

Also - can anyone recommend any rubber channel etc that would be appropriate here to stop the fairings rubbing / damaging the HS should it flex under G?

Thank you!

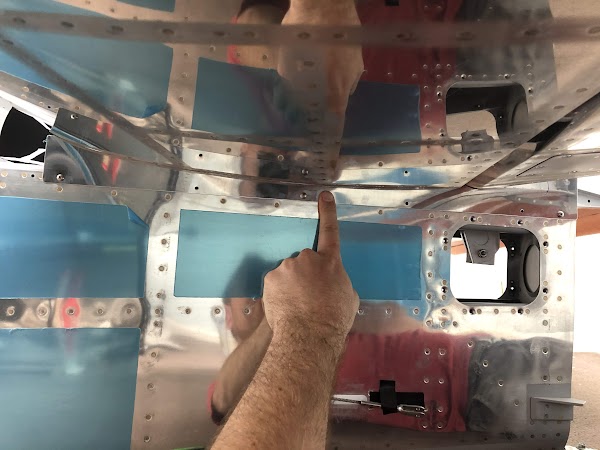

Here is a photo of the fairing I am talking about:

https://photos.app.goo.gl/u8KDznJ8PumWtcy26

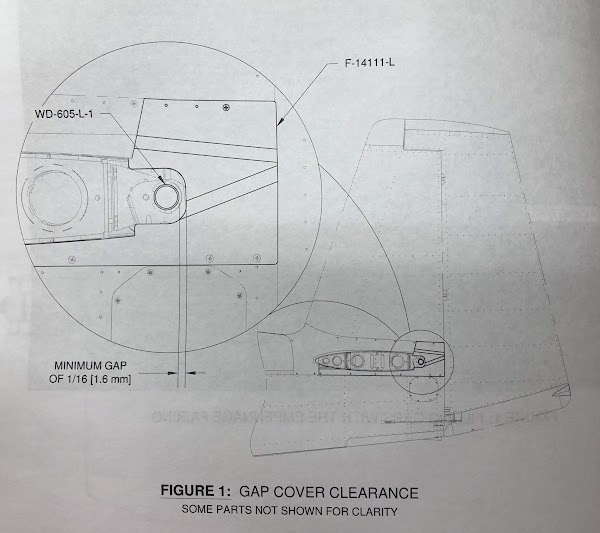

Here is the gap call out:

https://photos.app.goo.gl/UHPeQ5YYBEin525YA

Just wondering what sort of gap I should be looking for between the lower empennage gap covers (under the HS). I assume 1/16? would be ok since that?s the minimum gap around the elevator horns?

Also - can anyone recommend any rubber channel etc that would be appropriate here to stop the fairings rubbing / damaging the HS should it flex under G?

Thank you!

Here is a photo of the fairing I am talking about:

https://photos.app.goo.gl/u8KDznJ8PumWtcy26

Here is the gap call out:

https://photos.app.goo.gl/UHPeQ5YYBEin525YA