Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tie Down fitting ideas

- Thread starter jcbarker

- Start date

WildThing

Well Known Member

Off the top of my head: the removable 1st iteration will - lose the screw and be a pain to install (how to tighten the screw?) #2: the fairings with screw attach will get lost ASAP

Maybe just polish some standard stainless steel eye bolts and screw 'em out when you don't want them hanging out in the wind? Or maybe a spring loaded "cargo tie-down" plate/ring - it may be a little draggy, but nothing to remove.

Maybe just polish some standard stainless steel eye bolts and screw 'em out when you don't want them hanging out in the wind? Or maybe a spring loaded "cargo tie-down" plate/ring - it may be a little draggy, but nothing to remove.

RV8JD

Well Known Member

If you hangar, leave the tie down rings off and store them in the airplane for when they are needed.

These are nice, but pricey:

https://www.cleavelandtool.com/products/stainless-tie-down-ring?_pos=1&_sid=42fe9dd23&_ss=r

These are nice, but pricey:

https://www.cleavelandtool.com/products/stainless-tie-down-ring?_pos=1&_sid=42fe9dd23&_ss=r

If you hangar, leave the tie down rings off and store them in the airplane for when they are needed.

View attachment 26236

And use something similar to a bumper clip https://www.amazon.com/Fender-Bumper-Shield-Clips-Chrysler/dp/B0040CYSUW/ref=asc_df_B0040CYSUW/?tag=hyprod-20&linkCode=df0&hvadid=312684231807&hvpos=&hvnetw=g&hvrand=3331246816938016809&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9031318&hvtargid=pla-568793615266&psc=1&tag=&ref=&adgrpid=60983009663&hvpone=&hvptwo=&hvadid=312684231807&hvpos=&hvnetw=g&hvrand=3331246816938016809&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9031318&hvtargid=pla-568793615266 when flying

N804RV

Well Known Member

And use something similar to a bumper clip (URL="https://www.amazon.com/Fender-Bumper-Shield-Clips-....) when flying

I have a roll of white 2" wide vinyl tape (the kind used by glider pilots for anchoring gap seals). It's ideal for covering up holes like the ones left when you remove your tiedown rings. It stays on till you remove it. And, 1 roll has lasted me 4+ years and is still not run out.

I'll bet its easier to remove than those plastic clips! ;-)

Pricey but very nice and only 0.001kt TAS penalty

Perhaps not scientifically validated so expect YMETV

If you hangar, leave the tie down rings off and store them in the airplane for when they are needed.

These are nice, but pricey:

https://www.cleavelandtool.com/products/stainless-tie-down-ring?_pos=1&_sid=42fe9dd23&_ss=r

View attachment 26236

Perhaps not scientifically validated so expect YMETV

N804RV

Well Known Member

I know this probably sounds super ignorant on my part. But what is the reason for covering up or filling the holes when the tie down rings are removed?

To reduce drag and help prevent water intrusion. Whether it really makes a difference on your typical RV may be debatable. But hey, every little bit helps, right?

KenB

Active Member

To reduce drag and help prevent water intrusion.

Perhaps. Still I'm not seeing how a hole on the underside (as opposed to the top) of the wings creates any perceptible drag. And water is more likely to drip down than drip up.

Cheers, Ken

fixnflyguy

Well Known Member

Get the Cleveland tool ones..

I have the slick ones from Cleveland tool also, and they are usually stashed in my on board gig bag that also has short loops of robust small gauge rope attached to them. That way, when you end up at an airport with big fat frayed ropes that don't fit through small rings, you can still tie off to the nice small rope loops. If you align these nice fittings with the large diameter holes in line with the airstream, the drag is nill anyway, and they can be left in all the time (Minus the mentioned loops), barely visible to most.

I have the slick ones from Cleveland tool also, and they are usually stashed in my on board gig bag that also has short loops of robust small gauge rope attached to them. That way, when you end up at an airport with big fat frayed ropes that don't fit through small rings, you can still tie off to the nice small rope loops. If you align these nice fittings with the large diameter holes in line with the airstream, the drag is nill anyway, and they can be left in all the time (Minus the mentioned loops), barely visible to most.

Bill Boyd

Well Known Member

Will they double as jack points?

Something to consider.

I have the tall HF bottle jack thingie with a scooped-out ram end, and use acorn nuts on threaded shafts as jack points - these look like they might do double-duty.

I just used my jack last week to perform a pre-paint job W&B, and if paint goes on as hoped this weekend, will be able to answer the age-old question about how much a paint job adds to the empty weight of an RV-10 and how it shifts the empty CG.

Something to consider.

I have the tall HF bottle jack thingie with a scooped-out ram end, and use acorn nuts on threaded shafts as jack points - these look like they might do double-duty.

I just used my jack last week to perform a pre-paint job W&B, and if paint goes on as hoped this weekend, will be able to answer the age-old question about how much a paint job adds to the empty weight of an RV-10 and how it shifts the empty CG.

Ralph Inkster

Well Known Member

Note too that on every RV I've seen, that there is about a 1/8" gap between the bottom skin and the threaded tiedown bracket that's bolted to the spar. If you tighten the tiedown ring under the wing too much, you end up with a large ugly dimple in the skin.

RV8JD

Well Known Member

Hey everyone:

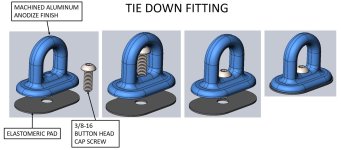

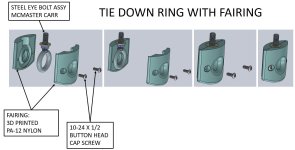

The idea was to have a decent looking tie down fitting that you wouldn't need to remove. Extra drag? Yes. Measurable? Don't think so.

Should have said so in your first post.

Anyway, here is a fairing set designed to be used with the Cleaveland tie down rings I linked in my Post #4. Easy on and off.

https://www.rvplasticparts.com/product-page/tie-down-fairing-set

Last edited:

David Paule

Well Known Member

I'm always bemused when people spend time and money and often add weight redesigning something that works nicely as-is.

The Cleaveland tie down ring is fine if you use a carabiner with it. With rope, the sharp edge will considerably weaken the rope under load. Rope is sensitive to stress concentrations just like aluminum is.

Dave

The Cleaveland tie down ring is fine if you use a carabiner with it. With rope, the sharp edge will considerably weaken the rope under load. Rope is sensitive to stress concentrations just like aluminum is.

Dave

Roadjunkie1

Well Known Member

Tiedown ring drag; hole drag; Whaaaaaaat??

Agreed and agreed. My (stock Van's) tie down rings are in my tool bag along with my control locks (VERY small and simple) and chocks. It takes me probably 10 seconds each to screw the rings in. I would imagine an unfilled hole causes some drag but would likely be measured in picograms of resistance.

I'm always bemused when people spend time and money and often add weight redesigning something that works nicely as-is.

The Cleaveland tie down ring is fine if you use a carabiner with it. With rope, the sharp edge will considerably weaken the rope under load. Rope is sensitive to stress concentrations just like aluminum is.

Dave

Agreed and agreed. My (stock Van's) tie down rings are in my tool bag along with my control locks (VERY small and simple) and chocks. It takes me probably 10 seconds each to screw the rings in. I would imagine an unfilled hole causes some drag but would likely be measured in picograms of resistance.

Scott Hersha

Well Known Member

I know this probably sounds super ignorant on my part. But what is the reason for covering up or filling the holes when the tie down rings are removed?

Mud daubers love it up in there - so go ahead and leave it open. Give a bug(s) a home.

rocketman1988

Well Known Member

Really?

With all the other holes and openings in the airplane, you actually think taping over the tie down holes is going to make a difference?

Mud daubers love it up in there - so go ahead and leave it open. Give a bug(s) a home.

With all the other holes and openings in the airplane, you actually think taping over the tie down holes is going to make a difference?

KenB

Active Member

Mud daubers love it up in there - so go ahead and leave it open. Give a bug(s) a home.

This is the first good reason I've seen so far for covering those holes. Well, unless you're a homeless mud dauber.

Our Airplane

Here’s what I did on the wingtips or our RV-6 after my local RV pals gave me grief for leaving the eyebolts under the wings. Besides, the tiedown rope or chain on the left usually fouls on the pitot tube. If folks really want me to, I’ll remove the wingtip and take a couple more photos.

Here’s what I did on the wingtips or our RV-6 after my local RV pals gave me grief for leaving the eyebolts under the wings. Besides, the tiedown rope or chain on the left usually fouls on the pitot tube. If folks really want me to, I’ll remove the wingtip and take a couple more photos.

Attachments

Last edited:

Here’s what I did on the wingtips or our RV-6 after my local RV pals gave me grief for leaving the eyebolts under the wings. Besides, the tiedown rope or chain on the left usually fouls on the pitot tube. If folks really want me to, I’ll remove the wingtip and take a couple more photos.

That’s slick!! Yeah show some details..

David Paule

Well Known Member

Here’s what I did on the wingtips or our RV-6 after my local RV pals gave me grief for leaving the eyebolts under the wings. Besides, the tiedown rope or chain on the left usually fouls on the pitot tube. If folks really want me to, I’ll remove the wingtip and take a couple more photos.

See post #18 about tight radii on tiedown fittings.

Dave

Scott Hersha

Well Known Member

With all the other holes and openings in the airplane, you actually think taping over the tie down holes is going to make a difference?

Yep…. I do.

rocketman1988

Well Known Member

Dad's RV-10

Well Known Member

There are numerous ties downs mentioned in this thread.I installed two of these and love them. I get many complements on how nice they look and how they don't create much drag. They ate well worth the money in my mind!

Which "these" did you install?

Photos, Phinally

Aw, man. I goofed up the photos… here are the correct ones. Sorry for the mess! So here’s how I did it. I scored a piece of .125” 7075-T6 at the local metal supply for the pivoting ring thingy. I’m sure 2024-T3 would be fine. The rest is simple sheet metal work and mostly AN hardware. There’s a 5/16” OD bushing on the pivot that the bolt tightens down on. I made up a couple of nylon washers to take the side loads. The spring is inelegant and I’d envisioned bending up a clock-type spring to install coaxial with the pivot, but I ran out of time. One of these days I’ll fix that. My CFI wife says it’s her favorite thing about the airplane. BTW, I spent a fair bit of time pondering this and came up with a number of bad ideas. This was finally was inspired by the tiedowns at the upper end of some of the Cessna struts, and locating them on the wingtips copies the Grumman single engine airplanes. They clear the pitot and they’re easier to reach. I just left the existing holes in the bottom of the wing as they are. This airplane is hangared so we don’t have problems with mud daubers, but if I go out of town of course I tape the holes. If I ever do another set, I’ll at least move the bolts a bit further apart so I wouldn’t need to trim those AN960 large area washers. If ya’ll have other ideas or refinements, I’d love to hear about them. Thanks for the interest!

Aw, man. I goofed up the photos… here are the correct ones. Sorry for the mess! So here’s how I did it. I scored a piece of .125” 7075-T6 at the local metal supply for the pivoting ring thingy. I’m sure 2024-T3 would be fine. The rest is simple sheet metal work and mostly AN hardware. There’s a 5/16” OD bushing on the pivot that the bolt tightens down on. I made up a couple of nylon washers to take the side loads. The spring is inelegant and I’d envisioned bending up a clock-type spring to install coaxial with the pivot, but I ran out of time. One of these days I’ll fix that. My CFI wife says it’s her favorite thing about the airplane. BTW, I spent a fair bit of time pondering this and came up with a number of bad ideas. This was finally was inspired by the tiedowns at the upper end of some of the Cessna struts, and locating them on the wingtips copies the Grumman single engine airplanes. They clear the pitot and they’re easier to reach. I just left the existing holes in the bottom of the wing as they are. This airplane is hangared so we don’t have problems with mud daubers, but if I go out of town of course I tape the holes. If I ever do another set, I’ll at least move the bolts a bit further apart so I wouldn’t need to trim those AN960 large area washers. If ya’ll have other ideas or refinements, I’d love to hear about them. Thanks for the interest!

Attachments

Last edited:

Aw, man. I goofed up the photos… here are the correct ones. Sorry for the mess! So here’s how I did it. I scored a piece of .125” 7075-T6 at the local metal supply for the pivoting ring thingy. I’m sure 2024-T3 would be fine. The rest is simple sheet metal work and mostly AN hardware. There’s a 5/16” OD bushing on the pivot that the bolt tightens down on. I made up a couple of nylon washers to take the side loads. The spring is inelegant and I’d envisioned bending up a clock-type spring to install coaxial with the pivot, but I ran out of time. One of these days I’ll fix that. My CFI wife says it’s her favorite thing about the airplane. BTW, I spent a fair bit of time pondering this and came up with a number of bad ideas. This was finally was inspired by the tiedowns at the upper end of some of the Cessna struts, and locating them on the wingtips copies the Grumman single engine airplanes. They clear the pitot and they’re easier to reach. I just left the existing holes in the bottom of the wing as they are. This airplane is hangared so we don’t have problems with mud daubers, but if I go out of town of course I tape the holes. If I ever do another set, I’ll at least move the bolts a bit further apart so I wouldn’t need to trim those AN960 large area washers. If ya’ll have other ideas or refinements, I’d love to hear about them. Thanks for the interest!

Not a structural engineer, but I would be concerned with those alum rings. It looks like 1/8 X 3/16" at the thinnest point. I struggle to see how aluminum of that size could hold up to the loads imparted during a strong blow from a T storm. The plans use 3/8" dia steel, threaded into a .5 X .5 X 6" chunk of alum bolted directly to the thick part of the spar. At least they did on the 6 and the 10; cant speak to the 14. Hard to tell from the pics, but look like it is using thin support material rivetted to a thin wing rib, possibly tied into the thin spar flange. This appears WAY less structurally sound than what Vans designed. Certainly not saying it won't hold, just saying that it seems substantially under engineered comparied to the original design.

I may have not fully understood your intent. Possibly you use the stock tie down rings in strong winds and these are just for burger runs in good wx. In that case, it is a neat approach. I just leave the rings in the tool bag and install them when tying down away from home when chocks alone are inadequate.

Larry

Last edited:

David Paule

Well Known Member

On the RV-3B, which sits very low to the ground, I was concerned about the sharp angle that the tiedown ropes made to the wing. That increases the load on the rope. Being a structural engineer, I looked at the loads if the tiedown points were located at the outboard end of the spar, and found that while the tiedown loads were reduced for the rope, they were too high for the spar; the spar might buckle, in spite of the rope's tension load. Your plane, with different geometry, might not have that problem. But it could still be a concern and you should check that.

It appears as if your tiedown ring is parallel to the airflow. If that's the case, it will be susceptible to the sideload since tie down ropes usually angle outboard to the wing in use. It could have bending loads high enough to cause problems on the ring even if the spar is okay. Another thing that you should check - ideally the ring will be parallel to the spar.

Dave

It appears as if your tiedown ring is parallel to the airflow. If that's the case, it will be susceptible to the sideload since tie down ropes usually angle outboard to the wing in use. It could have bending loads high enough to cause problems on the ring even if the spar is okay. Another thing that you should check - ideally the ring will be parallel to the spar.

Dave

PilotjohnS

Well Known Member

Like it a lot

I like these a lot. I have seen something similar on a sailplane, why back when. We have short wingspans as compared to most other planes. Being at the wing tips seems like it will be easier to tie up. I wish someone would make a retrofit kit.

The 7075 alloy is a good choice; nearly as strong as steel.

I see this being incorporated by the factory into the RV 15, (just saying)

Anyone, anyone, Bueller, anyone?

Edit: See later post by factory; this may be one instance where That Looks About Right engineering may not be the best. I will stick with factory

I like these a lot. I have seen something similar on a sailplane, why back when. We have short wingspans as compared to most other planes. Being at the wing tips seems like it will be easier to tie up. I wish someone would make a retrofit kit.

The 7075 alloy is a good choice; nearly as strong as steel.

I see this being incorporated by the factory into the RV 15, (just saying)

Anyone, anyone, Bueller, anyone?

Edit: See later post by factory; this may be one instance where That Looks About Right engineering may not be the best. I will stick with factory

Last edited:

wirejock

Well Known Member

Tie down thread

That's very odd. Vans has used 3/8 for quite a while.

I wonder why it changed?

Check McMaster

I'm looking at tie-down ring options and I was surprised to find that my -7 QB wings are threaded for 5/16" bolts so the rings from Van's and Cleaveland won't fit.

That's very odd. Vans has used 3/8 for quite a while.

I wonder why it changed?

Check McMaster

This airplane is hangared so we don’t have problems with mud daubers, but if I go out of town of course I tape the holes.

Not sure what kind of Mud Daubers you have in California, but the ones in Texas build inside hangars.

I'm looking at tie-down ring options and I was surprised to find that my -7 QB wings are threaded for 5/16" bolts so the rings from Van's and Cleaveland won't fit.

I wonder if someone tapped them 5/16 and don’t have full thread engagement? Or possibly used Helicoils to bring them down to that size? Either way, that’s odd..

Not a structural engineer, but I would be concerned with those alum rings. It looks like 1/8 X 3/16" at the thinnest point. I struggle to see how aluminum of that size could hold up to the loads imparted during a strong blow from a T storm. The plans use 3/8" dia steel, threaded into a .5 X .5 X 6" chunk of alum bolted directly to the thick part of the spar. At least they did on the 6 and the 10; cant speak to the 14. Hard to tell from the pics, but look like it is using thin support material rivetted to a thin wing rib, possibly tied into the thin spar flange. This appears WAY less structurally sound than what Vans designed. Certainly not saying it won't hold, just saying that it seems substantially under engineered comparied to the original design.

I agree with Larry.

There is a reason that the tie down anchors on RV's are designed the way they are.

The small cross section area of the small rings will be way deficient by comparison.

Keep in mind that when you really need a tie down to work, the load imparted can be quite high.

MacCool

Well Known Member

Should have said so in your first post.

Anyway, here is a fairing set designed to be used with the Cleaveland tie down rings I linked in my Post #4. Easy on and off.

https://www.rvplasticparts.com/product-page/tie-down-fairing-set

View attachment 26256

I have those Cleaveland tie downs and leave them on all the time. If it had been me, I'd have been just as happy with the rings. I did remove the Cleaveland item from the tail and replaced it with a ring in order to mount a Go Pro.

If I ever need to jack up the airplane such as at condition inspection, I replace the wing tie-downs with some grade 5 carriage bolts to use as jack points.

The previous owner of my plane apparently knew Scott Melton here and put on a pair of those, as well as other 3-D printed items. I have similar fairings for the sump drains, and fairings for the flap struts. They're secure, but don't really take paint well and look a little rough.

No clue about the aerodynamic effects of the Cleaveland tie downs and the 3-D fairings. I'm sure that there's no downside, not sure if there's any benefit.

Last edited:

David Paule

Well Known Member

....Keep in mind that when you really need a tie down to work, the load imparted can be quite high.

When I determined that wingtip tiedowns could overload the spar on an RV-3B, I was using 70 mph winds to assess that. Remember, that's based on RV-3B geometry which differs a bit from the other RVs. But the 70 mph is roughly what was encountered at Sun N Fun not that long ago, and LESS than I've personally experienced at Boulder, CO in '81, standing next to my C170, which was tied down.

Loads can indeed be quite high.

Dave

This is the first good reason I've seen so far for covering those holes. Well, unless you're a homeless mud dauber.

One of those little demons got into my house last week. I really don't want one living in my airplane!

Plug that Hole?

I'm thinking, without knowing any better, that when Van's says to remove the eye-bolt tie-downs before flight, that's what it means.

So I'm wondering if these would stay in place when the eye-bolts are not screwed into place, as in when flying?

https://www.widgetco.com/hole-plugs...gz1NTwM5dCMtQy8VmKJleDS2vcSXqqiIaAhUKEALw_wcB

I'm thinking, without knowing any better, that when Van's says to remove the eye-bolt tie-downs before flight, that's what it means.

So I'm wondering if these would stay in place when the eye-bolts are not screwed into place, as in when flying?

https://www.widgetco.com/hole-plugs...gz1NTwM5dCMtQy8VmKJleDS2vcSXqqiIaAhUKEALw_wcB

Why not grind some of the trailing edge off and make it the classic tear drop pressure recovery shape?

As robust as the standard Vans rings are, I think they would still be sufficiently strong enough to do their job.

That’s what my plan is and I plan to leave them in place. I don’t like the idea of wear on the aluminum threads from the steel threads that would occur over time from repeated insertion/removal or an invitation to mud daubers.

As a bonus, if a person could find some type of rubber wheel shaped like a tire rim to leave in place when not in use, it would look and act like wheel pants. Or even two buttons that could be easily separated by using something like magnets. Make each button from 2 hole saw circles. One to cover and one slightly smaller to prevent movement. JB Weld a button magnet on one side and washer stack on the other. When needed, easy to remove.

It would be a 9 to 1 reduction in drag if you use the round to teardrop methodology. Hey, a speed mod!

As robust as the standard Vans rings are, I think they would still be sufficiently strong enough to do their job.

That’s what my plan is and I plan to leave them in place. I don’t like the idea of wear on the aluminum threads from the steel threads that would occur over time from repeated insertion/removal or an invitation to mud daubers.

As a bonus, if a person could find some type of rubber wheel shaped like a tire rim to leave in place when not in use, it would look and act like wheel pants. Or even two buttons that could be easily separated by using something like magnets. Make each button from 2 hole saw circles. One to cover and one slightly smaller to prevent movement. JB Weld a button magnet on one side and washer stack on the other. When needed, easy to remove.

It would be a 9 to 1 reduction in drag if you use the round to teardrop methodology. Hey, a speed mod!

Last edited: