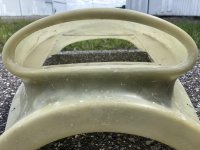

Novel approach or doomed to failure? The scoop to air box I/F is less than aerodynamically smooth. I’ve got one of the older legacy designs. Didn’t want to fill with that much dry micro. Trying to fill with foam wasn’t going well. After looking for a dissolvable mold core material, I experimented with cheap-a$$ drywall joint compound.

Known bad = Yes it shrinks. Yes it takes time to dry thick fills. Yes it cracks.

Potential good =. It’s cheap. Available most anywhere. Cleans/dissolves with water. Sand-able or smooths with water and sponge, finger, etc.

I filled a 1” pipe and let it dry. It “hydroblasted” out with a siphon gun and water. An occasional gouged hole speeds things up as you’d imagine. Have the deep parts rough filled and will soon smooth and glass it in. Hopefully it works or it may be a complete waste of time. I’ll pass along. Hopefully another cheap method for dealing with similar issues in the future.

Known bad = Yes it shrinks. Yes it takes time to dry thick fills. Yes it cracks.

Potential good =. It’s cheap. Available most anywhere. Cleans/dissolves with water. Sand-able or smooths with water and sponge, finger, etc.

I filled a 1” pipe and let it dry. It “hydroblasted” out with a siphon gun and water. An occasional gouged hole speeds things up as you’d imagine. Have the deep parts rough filled and will soon smooth and glass it in. Hopefully it works or it may be a complete waste of time. I’ll pass along. Hopefully another cheap method for dealing with similar issues in the future.