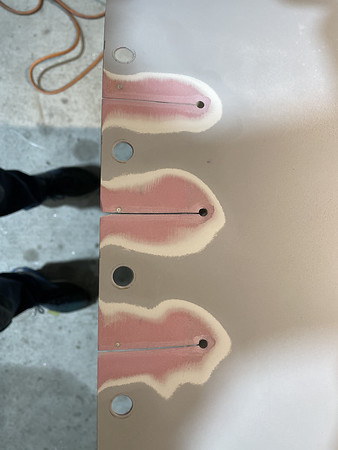

This thread has been most helpful. No scallops for me. Used 0.032 spacer for the carbon fiber stiffeners.

Will be using ~3” spacing. Am I missing anything?

.

View attachment 53866

That looks great Webb, I would hold off on riveting, or even deciding what thickness of shim to put between the Skybolt mounting strip and the inner face of the cowl flange, until after you have done the actual cowl stiffening so you know just how thick it comes out, and adjust the shim strip accordingly. You may have done that, sorry if I missed that. But adding that thought may help others.

To the question of what type of carbon to use, I would use some of both uni and bi-directional. The uni is the most effective at stiffening between the fasteners, minimizing the bulges. Then, I would finish with a ply of bi-directional over the top of that and lapping up onto the existing cowl glass, maybe 2" or 2.5" wide. This will help with stiffening the edge in the direction of edge-flexing when you handle it.

As a rough ballpark, you can count on uni tapes being 0.005"--0.008" thick, and 0.010"--0.012" for the bi-directional cloth, depending on weight of fibers. I'm assuming 3K fibers, which is probably the most common. A fanatic would say to put a ply of fiberglass over the top of all those so that you don't have carbon contact against aluminum, but the aluminum will presumably be primed, the carbon is all epoxy-coated, and this isn't like a structural bond where a little bit of corrosion can destroy the bond. But I do keep a roll of very light weight, fine weave fiberglass tape, 2", for exactly this purpose.

Also when you lay those tapes in, put a strip of peel-ply over them and smooth that out with some pressure. This will work some of the excess resin out, help distribute the resin in case you have any air bubbles or lean spots, and give you a nice smooth surface when it cures and you peel that off.

BTW, I used 3.0" spacing and kind of wished I had used 2.5". Before I reduced my cowl exit area, the cowl layed pretty flat between fasteners in flight. But now, with the higher internal cowl pressure, I see more bulging. Next time, I'll use carbon instead of glass, as I've described here, and may opt for the closer spacing too.