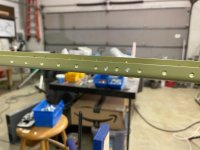

Hi all. I screwed up and put a "figure 8" dimple hole in one of my horizontal stab skins. Fortunately it's on a bottom trailing edge. So my fix is to put two rivets equal distance on either side. I drilled out any raggedness from the male die. I plan on putting some JB Weld in the damaged hole, and rivet all 3. Good plan?

I thought about just using JB Weld and a rivet in the damaged hole, or go up to a 4, but this seems like the approach most recommended?

Let me know if it's going to fall out of the sky.

I thought about just using JB Weld and a rivet in the damaged hole, or go up to a 4, but this seems like the approach most recommended?

Let me know if it's going to fall out of the sky.