Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RTV Fiberglass

- Thread starter wirejock

- Start date

Kyle Boatright

Well Known Member

I remember reading someone using RTV sarurated fiberglass to seal baffle gaps. Seems like they squeegee it between plastic and allow it to cure.

Any tips?

Which RTV? Red High Temp?

I used the black high temp RTV and ~3 layers of glass, squeegeeing the RTV into the layers between layers of wax paper. Then I cut the wax paper and fiberglass layup to shape (the pieces should match the contact patches of your aluminum baffles), peeled the wax paper off one side of the layup, and applied it to the baffles so the wet RTV made it stick. Installed the baffles over the fiberglass/RTV as a backside support to make sure the layup didn't suffer a blowout, and all was good. I did apply a stripe of RTV at the "exit" end of the gap seals to glue them to the fins and the aluminum baffles.

3 years in with this on one side of the engine, and all is well. The temperatures on that side are several degrees (like 5 or 10) cooler than the other side. They were equal before.

You ask why I only did one side? I saw some baffle wear on one side, pulled the baffles on that side to make repairs, and added the RTV/Glass before I reinstalled the aluminum baffles on those 2 cylinders.

I'll probably do the other side one of these days.

pazmanyflyer

Well Known Member

I remember reading someone using RTV sarurated fiberglass to seal baffle gaps. Seems like they squeegee it between plastic and allow it to cure.

Any tips?

Which RTV? Red High Temp?

The infamous Dan Horton. Page 4 - Post #38

https://vansairforce.net/community/showthread.php?t=37835&page=4

Kyle Boatright

Well Known Member

I read RTV cures in humidity. That's a problem up here.

Our humidity is really low.

I'm sure it'll cure no problem, but if it is a concern, a trial tube of RTV is like $5.

Larry, use Permatex Ultra Black, available at almost any auto parts store. Also known as Loctite 598, same thing. Highly oil resistant, same temp rating as the ugly orange stuff, nice charcoal color.

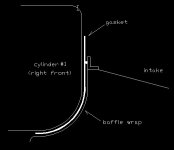

Be sure to run a small bead across the aluminum wrap near the entrance end before placing it over the RTV/glass gasket. Allowing an air leak between the gasket and the aluminum wrap would defeat the purpose. It's the little dot below.

I like 4 mil plastic for working the RTV into the glass. Clean the ends of the fins before you stick the patch into place. Leave the plastic on the exposed side. After cure, peel the plastic to expose a nice smooth surface.

.

Be sure to run a small bead across the aluminum wrap near the entrance end before placing it over the RTV/glass gasket. Allowing an air leak between the gasket and the aluminum wrap would defeat the purpose. It's the little dot below.

I like 4 mil plastic for working the RTV into the glass. Clean the ends of the fins before you stick the patch into place. Leave the plastic on the exposed side. After cure, peel the plastic to expose a nice smooth surface.

.

Attachments

Last edited:

BillL

Well Known Member

You can read between Dan's lines here, but to be clear - peel one side off before it cures and apply that to the fins. The adhesion is quite good. Remember, the tips of the fins are the coolest.Larry, use Permatex Ultra Black, available at almost any auto parts store. Also known as Loctite 598, same thing. Highly oil resistant, same temp rating as the ugly orange stuff, nice charcoal color.

Be sure to run a small bead across the aluminum wrap near the entrance end before placing it over the RTV/glass gasket. Allowing an air leak between the gasket and the aluminum wrap would defeat the purpose. It's the little dot below.

I like 4 mil plastic for working the RTV into the glass. Clean the ends of the fins before you stick the patch into place. Leave the plastic on the exposed side. After cure, peel the plastic to expose a nice smooth surface.

.

wirejock

Well Known Member

Larry, use Permatex Ultra Black, available at almost any auto parts store. Also known as Loctite 598, same thing. Highly oil resistant, same temp rating as the ugly orange stuff, nice charcoal color.

Be sure to run a small bead across the aluminum wrap near the entrance end before placing it over the RTV/glass gasket. Allowing an air leak between the gasket and the aluminum wrap would defeat the purpose. It's the little dot below.

I like 4 mil plastic for working the RTV into the glass. Clean the ends of the fins before you stick the patch into place. Leave the plastic on the exposed side. After cure, peel the plastic to expose a nice smooth surface.

.

Thanks Dan

I also want some pieces to seal obvious leakage gaps before some baffle parts are riveted together. I'll make some test pieces.

PilotjohnS

Well Known Member

wear

OK so help me understand if this is correct:

1) Normally the baffles sit directly against the cylinders? Is this correct, but isn't there chaffing wear there?

2) You saw some wear on the baffles, so you added the RTV fabric stuff to seal the gap between the baffle and the cylinders and also prevent the chaffing wear?

You ask why I only did one side? I saw some baffle wear on one side, pulled the baffles on that side to make repairs, and added the RTV/Glass before I reinstalled the aluminum baffles on those 2 cylinders.

I'll probably do the other side one of these days.

OK so help me understand if this is correct:

1) Normally the baffles sit directly against the cylinders? Is this correct, but isn't there chaffing wear there?

2) You saw some wear on the baffles, so you added the RTV fabric stuff to seal the gap between the baffle and the cylinders and also prevent the chaffing wear?

wirejock

Well Known Member

Application

Is there any problem with applying the un-cured fabric to the baffle and allowing it to cure before installation?

You can read between Dan's lines here, but to be clear - peel one side off before it cures and apply that to the fins. The adhesion is quite good. Remember, the tips of the fins are the coolest.

Is there any problem with applying the un-cured fabric to the baffle and allowing it to cure before installation?

David Paule

Well Known Member

Fewer plies of glass makes it weaker but more flexible. How much strength do you need? It's a gasket.

To some extent, a 45 degree fiber orientation will be more flexible than a 0/90 degree orientation.

Dave

To some extent, a 45 degree fiber orientation will be more flexible than a 0/90 degree orientation.

Dave

There is no flexibility issue.

My wraps are one ply of 9oz, but I really like Kyle's suggestion of three plies.

Larry, stick it to the fins. See below.

The glass gasket wrap does help with chafing wear, but the real goal is to make sure the air stays between the fins all the way to an exit near the spark plug and CHT probe. Plain aluminum wraps tend to leak a lot of air out the sides, meaning it doesn't pick up as much heat as it could have.

.

My wraps are one ply of 9oz, but I really like Kyle's suggestion of three plies.

Larry, stick it to the fins. See below.

The glass gasket wrap does help with chafing wear, but the real goal is to make sure the air stays between the fins all the way to an exit near the spark plug and CHT probe. Plain aluminum wraps tend to leak a lot of air out the sides, meaning it doesn't pick up as much heat as it could have.

.

Attachments

Kyle Boatright

Well Known Member

OK so help me understand if this is correct:

1) Normally the baffles sit directly against the cylinders? Is this correct, but isn't there chaffing wear there?

2) You saw some wear on the baffles, so you added the RTV fabric stuff to seal the gap between the baffle and the cylinders and also prevent the chaffing wear?

Yes. I noticed the cylinder fins about to wear through a portion of the baffles. So I repaired the baffles and added the RTV/fiberglass as a performance enhancement and wear preventative.

wirejock

Well Known Member

RTV cure

Apparently RTV needs humidity to cure. That's what I've read.

We live at 7500'. Humidity is 20% in my shop. The RTV in between plastic didn't cure at all in 24 hours in the furnace room. Probably 90 degrees. One side was peeled open today and it sort of cured in the furnace room. It's still kinda sticky. This is why I posted.

There's no way to put the engine in a warm humid environment to cure RTV/fiberglass sheets applied to the cylinders. I don't want a gooey mess waiting to cure. I could run a heater, but don't like to leave one running when I'm not present. I doubt a humidifier will make much difference in the shop. Even with a propane heater, humidity never rises above 25%. Way under the recommended humidity.

Another sample is curing in the shop to see how long it takes.

I may set up a box with a humidifier to cure sheets and use them after they cure. I can apply it to the baffle and cure in the box. Probably not as efficient as sealing the cylinder fins, but it won't make a mess.

Apparently RTV needs humidity to cure. That's what I've read.

We live at 7500'. Humidity is 20% in my shop. The RTV in between plastic didn't cure at all in 24 hours in the furnace room. Probably 90 degrees. One side was peeled open today and it sort of cured in the furnace room. It's still kinda sticky. This is why I posted.

There's no way to put the engine in a warm humid environment to cure RTV/fiberglass sheets applied to the cylinders. I don't want a gooey mess waiting to cure. I could run a heater, but don't like to leave one running when I'm not present. I doubt a humidifier will make much difference in the shop. Even with a propane heater, humidity never rises above 25%. Way under the recommended humidity.

Another sample is curing in the shop to see how long it takes.

I may set up a box with a humidifier to cure sheets and use them after they cure. I can apply it to the baffle and cure in the box. Probably not as efficient as sealing the cylinder fins, but it won't make a mess.

PaulvS

Well Known Member

Silicone rubber?

There is 2-part silicone molding rubber available, it cures by chemical reaction and does not need humidity.

Here is an example that has high temp rating. I have not tested it.

https://www.smooth-on.com/products/mold-max-60/

There is 2-part silicone molding rubber available, it cures by chemical reaction and does not need humidity.

Here is an example that has high temp rating. I have not tested it.

https://www.smooth-on.com/products/mold-max-60/

Last edited:

Kyle Boatright

Well Known Member

Apparently RTV needs humidity to cure. That's what I've read.

The layup wasn't going to cure trapped between 2 layers of plastic -moisture couldn't get to it. That said, I believe you're over-thinking it. With one side exposed to the atmosphere, it'll eventually cure. Might take a day, might take two, might take 3, but it is gonna cure.

I may set up a box with a humidifier to cure sheets and use them after they cure. I can apply it to the baffle and cure in the box. Probably not as efficient as sealing the cylinder fins, but it won't make a mess.

You realize the plan is to peel the plastic from one side, stick that side to the tips of the fins, allow cure, then peel the exposed side?

wirejock

Well Known Member

You realize the plan is to peel the plastic from one side, stick that side to the tips of the fins, allow cure, then peel the exposed side?

Yes. The tests were intended to check cure rate. I didn't want something gooey on the engine waiting days to cure and becoming a mess.

Thanks. Correct. The RTV will cure. Temp doesn't seem to matter.The layup wasn't going to cure trapped between 2 layers of plastic -moisture couldn't get to it. That said, I believe you're over-thinking it. With one side exposed to the atmosphere, it'll eventually cure. Might take a day, might take two, might take 3, but it is gonna cure.

One sample was in the furnace room @ 90

One sample was in the shop @ 60.

Both cured in 24 hours to tacky. Fully cured in 48. Tacky but the black doesn't transfer to my fingers.

At least I know how long they need to stay on the engine before pulling the exposed side plastic.

I can also make some pieces to use as gaskets in other areas.

Last edited: