Hi folks,

Am sizing up the conversion of an O-320 with MA4-SPA carb to an ECI IO-340 with hot sump (Updraft). I would like to use the AFP FM150 FI system. I have a few questions:

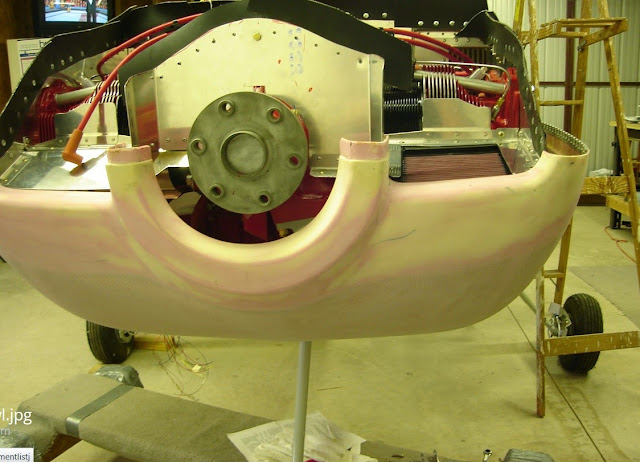

1. Will using FM150 servo require modifying the lower cowling. My MA4-SPA carb measures 4.5 inches. I saw a post on VAF that the FM150 servo is 5.5 inches. Currently, there is less than 1 inch clearance between the FAB and the lower cowling. Has anyone made modifications in this area? Is there a work around? Is modifying the lower cowl required?

2. Will the FM 150 servo connect to the Vans FAB box without modification?

3. How about control cables, brackets? Any changes needed there?

Thanks in advance for your help.

Don

RV9a N754RK flying

RV7A - building...

Am sizing up the conversion of an O-320 with MA4-SPA carb to an ECI IO-340 with hot sump (Updraft). I would like to use the AFP FM150 FI system. I have a few questions:

1. Will using FM150 servo require modifying the lower cowling. My MA4-SPA carb measures 4.5 inches. I saw a post on VAF that the FM150 servo is 5.5 inches. Currently, there is less than 1 inch clearance between the FAB and the lower cowling. Has anyone made modifications in this area? Is there a work around? Is modifying the lower cowl required?

2. Will the FM 150 servo connect to the Vans FAB box without modification?

3. How about control cables, brackets? Any changes needed there?

Thanks in advance for your help.

Don

RV9a N754RK flying

RV7A - building...