Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

high oil pressure during new engine break in

- Thread starter dwranda

- Start date

Depending on what engine you have, the redline oil pressure is probably 90 psi. So, you might be on the high end of allowable. Usually, it’s very easy to adjust the oil pressure down. But let us know what engine you have, or if the engine in question is the one in your signature block, and you will get better advice.

Last edited:

Hard to define normal, as there is an adjustment for the oil pressure. Be advised that the pressure will vary with oil temperature at any given adjustment point. It is normal for Pressure to drop with RPMs, but the point at which it starts dropping is quite variable engine to engine

fl-mike

Well Known Member

Looks like your #2 cyl instrumentation is bad.

Anyway, leave alone for now. You are also getting some blow-by that will affect oil pressure until the rings seat, so you may see some fluctuation with manifold pressure. A bit higher pressure won't hurt anything. The max is 115psi. 80-90 is a good target. Take a look at your data logs. You probably get your max at takeoff.

I'm fighting just the opposite with my new engine. I keep turning in the oil bypass valve spring screw to the point I'm wondering if they put the wrong spring in the valve.

Anyway, leave alone for now. You are also getting some blow-by that will affect oil pressure until the rings seat, so you may see some fluctuation with manifold pressure. A bit higher pressure won't hurt anything. The max is 115psi. 80-90 is a good target. Take a look at your data logs. You probably get your max at takeoff.

I'm fighting just the opposite with my new engine. I keep turning in the oil bypass valve spring screw to the point I'm wondering if they put the wrong spring in the valve.

RV8JD

Well Known Member

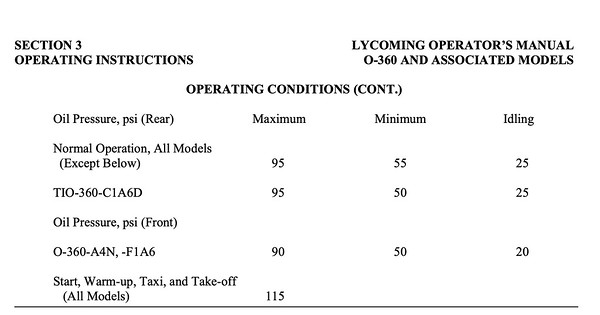

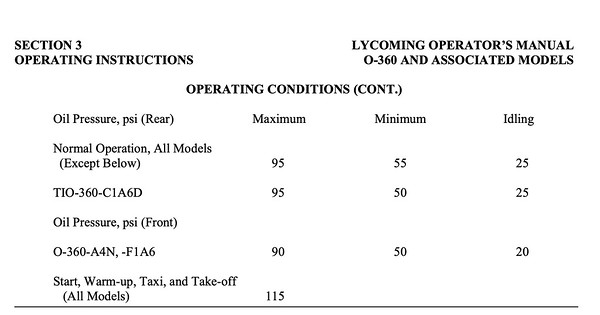

Below is a screenshot from the "O-360, HO-360, IO-360, AIO-360, HIO-360 & TIO-360 Operator's Manual", page 3-12, noting the maximum oil pressures. Not sure about the Mattituck TMX IO-360, but probably similar, if not the same, i.e., 95 psi.

Page 5-5 explains how to adjust the pressure relief valve.

Page 5-5 explains how to adjust the pressure relief valve.

Last edited:

Thanks. I think I have a bad EGT sensor on cylinder 2. Looking at the engine data for the almost 2 hour flight, the oil pressure was 88 in the first hour then at full power in the 2nd hour it was usually 86. Sounds like the consensus is that it is OK at that reading. It's amazing to be able to go back and look at the incredible amount of data provided by the AFS equipment.

fl-mike

Well Known Member

Thanks. I think I have a bad EGT sensor on cylinder 2. Looking at the engine data for the almost 2 hour flight, the oil pressure was 88 in the first hour then at full power in the 2nd hour it was usually 86. Sounds like the consensus is that it is OK at that reading. It's amazing to be able to go back and look at the incredible amount of data provided by the AFS equipment.

Both CHT and EGT look wacky on #2, at least at the moment the photo was taken. Yes, the data logging is a great feature and really offloads you on the test flights.

Both CHT and EGT look wacky on #2, at least at the moment the photo was taken. Yes, the data logging is a great feature and really offloads you on the test flights.

Upon removing the cowl to inspect the engine after the first flight we discovered the CHT probe had fallen out and was just dangling. That was the reason for the wacky reading. Good catch!!

MacCool

Well Known Member

Thanks. I think I have a bad EGT sensor on cylinder 2. Looking at the engine data for the almost 2 hour flight, the oil pressure was 88 in the first hour then at full power in the 2nd hour it was usually 86. Sounds like the consensus is that it is OK at that reading. It's amazing to be able to go back and look at the incredible amount of data provided by the AFS equipment.

In case you’re not aware, you can upload those files to Savvy and they will track that data for you. If you pay them $129/year, they’ll interpret it for you and give their opinion on how your engine is doing, and interpret the trends.

https://www.savvyaviation.com/

tommylewis

Well Known Member

similar

I now have 9 hours on a new Lycoming Thunderbolt IO360M1B and I have very similar oil pressures. Once it warms up, the oil pressure settles to about 82-84. After looking at oil pressures on the test cell data provided by Lycoming, I believe Lycoming set the oil pressure for about 80. I am leaving mine where it is at. Love this new engine.

I now have 9 hours on a new Lycoming Thunderbolt IO360M1B and I have very similar oil pressures. Once it warms up, the oil pressure settles to about 82-84. After looking at oil pressures on the test cell data provided by Lycoming, I believe Lycoming set the oil pressure for about 80. I am leaving mine where it is at. Love this new engine.

We normally set the oil pressure to be 70-80 psi, for cruise RPM, in the test cell. Yours is a bit above that but you are also running at a higher cruise RPM. I would check the integrity of the pressure reading and if accurate I would turn the oil pressure adjustment out 2-3 turns and see what that yields at 1400 rpm with above 120 f oil temp on the ground. When the pressure is set to 60psi, by adjusting the relief valve in or out, at 1400 rpm with the oil above 120F, on the ground, the oil pressure at cruise with 180F oil temp will be 75psi, which is the middle of the green.

Happy New Year,

Mahlon

Happy New Year,

Mahlon

What type of Oil ?

What type of Oil are you using ? 80 or 100.

It is important to use the correct oil for the surrounding air temperature.

https://www.shell.com/business-cust...da955d588ce5/theaeroshellbook-edition2021.pdf

Good luck

What type of Oil are you using ? 80 or 100.

It is important to use the correct oil for the surrounding air temperature.

https://www.shell.com/business-cust...da955d588ce5/theaeroshellbook-edition2021.pdf

Good luck

We normally set the oil pressure to be 70-80 psi, for cruise RPM, in the test cell. Yours is a bit above that but you are also running at a higher cruise RPM. I would check the integrity of the pressure reading and if accurate I would turn the oil pressure adjustment out 2-3 turns and see what that yields at 1400 rpm with above 120 f oil temp on the ground. When the pressure is set to 60psi, by adjusting the relief valve in or out, at 1400 rpm with the oil above 120F, on the ground, the oil pressure at cruise with 180F oil temp will be 75psi, which is the middle of the green.

Happy New Year,

Mahlon

How would I go about checking the integrity of the pressure reading? So good to hear from the Mattituck expert!!! Thanks Mahlon

How to verify pressure

The oil pressure transducer is likely mounted on the firewall, probably in a manifold. If so, there may be an "available port" on the manifold, e.g. one port has an oil line coming in, one has the pressure transducer, and one is plugged. Use an analog gauge on the end of a threaded hose that can be screwed into the available manifold port. Compare the values on your EIS v those of the analog gauge. Remember that the threads are NPT, so thread sealant is necessary when you button everything back up.

I just replaced an oil pressure transducer yesterday, with a test run planned for tomorrow. At "pre-oiler" pressures, the readings were pretty close, but at operating engine pressures (~80 at 1700 rpm with warm oil) they diverged. The EIS was reading 99--which is the highest reading the software will display, so I was somewhat concerned that it could be even higher. Eighty had been the warm oil norm at runup and cruise until just recently, when I began to see higher pressures.

Be careful!!! Obvious precautions are needed if you do this test and the length of the hose is such that someone needs to stand near a moving prop to read the analog gauge.

How would I go about checking the integrity of the pressure reading? So good to hear from the Mattituck expert!!! Thanks Mahlon

The oil pressure transducer is likely mounted on the firewall, probably in a manifold. If so, there may be an "available port" on the manifold, e.g. one port has an oil line coming in, one has the pressure transducer, and one is plugged. Use an analog gauge on the end of a threaded hose that can be screwed into the available manifold port. Compare the values on your EIS v those of the analog gauge. Remember that the threads are NPT, so thread sealant is necessary when you button everything back up.

I just replaced an oil pressure transducer yesterday, with a test run planned for tomorrow. At "pre-oiler" pressures, the readings were pretty close, but at operating engine pressures (~80 at 1700 rpm with warm oil) they diverged. The EIS was reading 99--which is the highest reading the software will display, so I was somewhat concerned that it could be even higher. Eighty had been the warm oil norm at runup and cruise until just recently, when I began to see higher pressures.

Be careful!!! Obvious precautions are needed if you do this test and the length of the hose is such that someone needs to stand near a moving prop to read the analog gauge.