IowaRV9Dreamer

Well Known Member

I've got the tail mounted to the fuselage and am trying to install the Vans rudder stops. I'm not exactly sure of the travel, but something seems to be wrong:

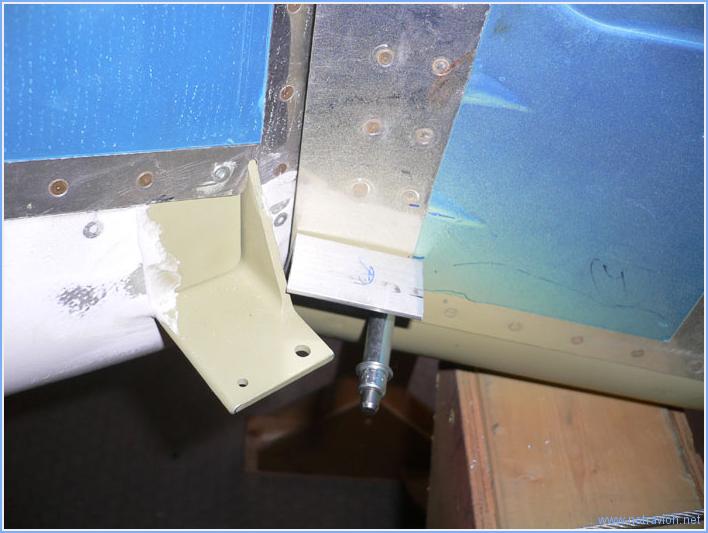

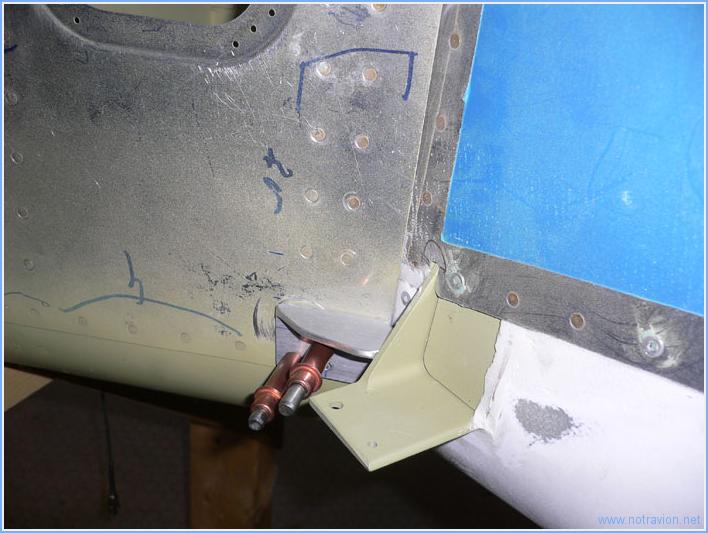

The rudder stop isn't able to hit the arm - it runs into the rudder's spar first. In the picture of the left rudder stop, I have the rudder in the approximate 35 degree position. You can see that the rudder spar (painted grey primer) it touching the stop. If I were to move the stop back to engage the control bar the problem just gets worse.

The rudder stops seem pretty close to the plans drawings. I think the rudder travel is right-ish. If anything it might be too low. I may need to extend the rudder rod end bearings a turn or two, because the rudder is just touching the VS at what I think is 35 degrees.

Someone please tell me what I"m doing wrong! I can't move the rudder stop down under the spar, because then it just barely lines up with the control bar.

At about 35 degrees, there is a bit under an inch of clearance between the rudder and elevator. Can any RV-9A people verify that?

Argh - I'm starting to want one of those delrin stops.

The rudder stop isn't able to hit the arm - it runs into the rudder's spar first. In the picture of the left rudder stop, I have the rudder in the approximate 35 degree position. You can see that the rudder spar (painted grey primer) it touching the stop. If I were to move the stop back to engage the control bar the problem just gets worse.

The rudder stops seem pretty close to the plans drawings. I think the rudder travel is right-ish. If anything it might be too low. I may need to extend the rudder rod end bearings a turn or two, because the rudder is just touching the VS at what I think is 35 degrees.

Someone please tell me what I"m doing wrong! I can't move the rudder stop down under the spar, because then it just barely lines up with the control bar.

At about 35 degrees, there is a bit under an inch of clearance between the rudder and elevator. Can any RV-9A people verify that?

Argh - I'm starting to want one of those delrin stops.