"From MIT" sounds impressive, but the referenced document is a grad student paper....

Dan you are dismissive of Grad Students at MIT? Ha ha. One of your questions, ‘what acid’. I explained and overall PH of the stuff coming out of vent is “nasty” and acidic. You apparently disagree with no rebuttle. I win this point and your qualification of source is noted.

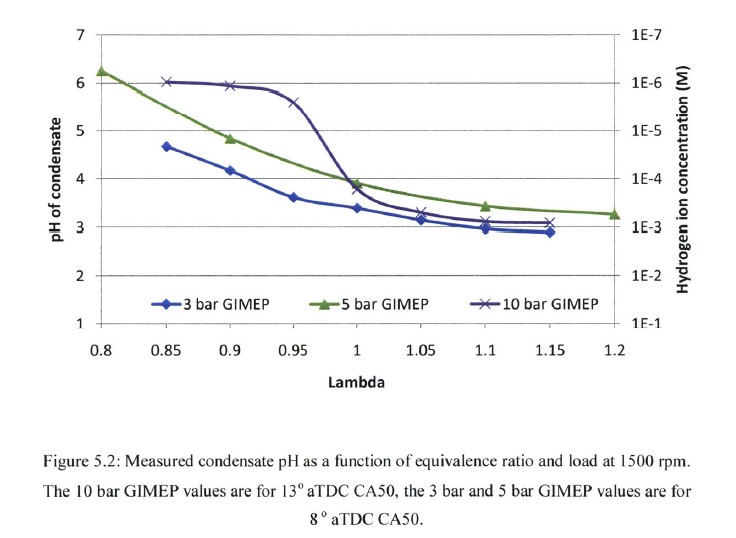

"The student predicted PH of the condensate in an EGR cooler would be 2 to 4. When the student actually measured the PH, it ranged from 3 to 6, with lambda (approximately peak EGT) being about 4.

You are obfuscating. My point is oh so simple. The vaporized, aerosolized stuff that comes out vent is NOT worth collecting, in my opinion. You can’t avoid returning undesirable chemicals and moisture back into engine in solution with oil or emulsified liquids.

You say it will all burn off the bad stuff when HOT. Yes separator or no separator it burns off if you fly often and change oil at 25 hours. It may take longer with an air/oil can draining back into engine. Another part of the vent gases is combustion products due to blow-by, SO2 for example. Aerosolized oil, thrown off internal moving parts, crank, rods, cam, accessory case gears is good. Yes you could collect that. No simple air/oil “can” separates and purifies oil regardless of sales claims in my opinion. The amount of oil saved is small.

My proof comes from experience with air/oil separators. My oil use is nominal. My aircraft belly needs a cleaning every once and awhile. I am good with that. How many planes fly without air/oil separator? Vast numbers. FAR’s require them? No. I avoid weight, clutter under cowl if possible. Air/oil separators can increase vent backpressure. Anything to promote a dryer internal engine environment and reducing contamination of oil is my priority.

"Rich and high IMEP (full throttle) was 6.

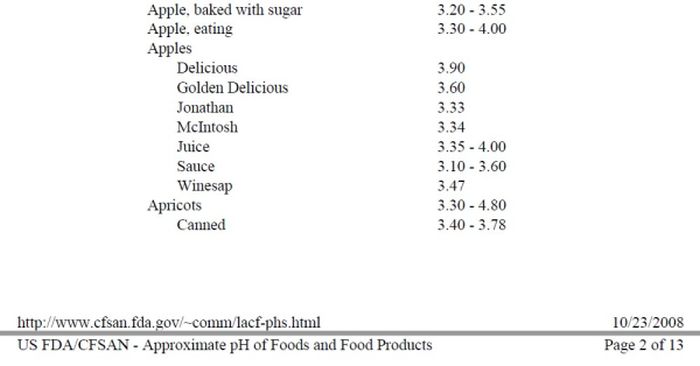

...... Perhaps a wee bit excessive. Not that it matters a whole lot (the above PH values were for water condensed in an exhaust cooler), but a PH of 4 isn't so bad. Apples are in the threes:.

What is your point. "Not that bad". OK. You concede this point the condensate is acidic and gets into crank case. You don’t think this with moisture can increase contamination of engine oil and promote corrosion (especially is disused engines). You can throw all kind of obfuscation at this, but the vented stuff is definitely not neutral or desirable. Why capture anything from vent? Small loss in oil. I just don't think it's worth it. That is my story and sticking to it.

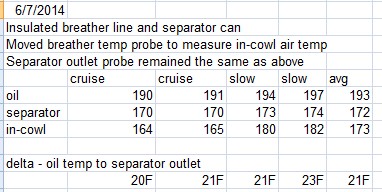

"Sure. The question you were asked was "Do you know why"? Correct. If gas temperature is maintained above the dew point of the vapor content, it remains in vapor phase, and the separator has no effect on that content. It's a gas. The separator can only catch materials in liquid phase. .

Of course correct. You are ignoring the point and mis-quoting me. You feeding condensed crank case gases and droplets back to the engine is dubious. You claim your air/oil separator is special. OK. Prove it.

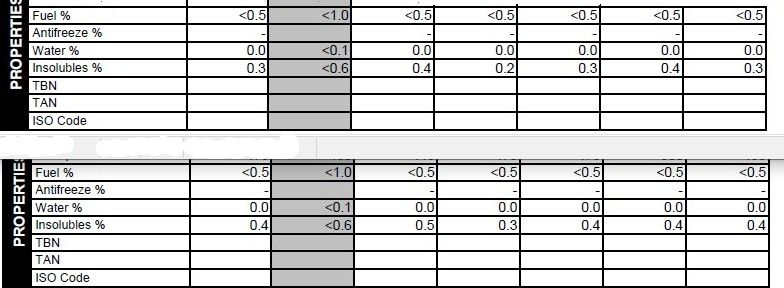

Dan take measurements with and with drain tube off your air/oil separator and collect it in a bottle. Do a before and after. Is belly cleaner? Is oil consumption down? What is the oil analysis of catch bottle? What is crank case oil analysis before and after air/oil separator draining back to crank case. Oil gets BLACK and we change it every 25 hours. In a car by hours, that is an oil change every 3 to 4 weeks. Yes oil will get dirty regardless by why help it get more contaminated, even if just a little.

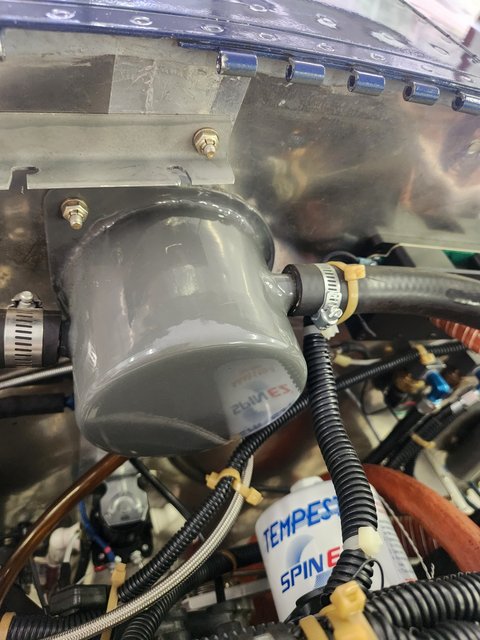

Return to "Do you know why?" The Walker separator, marketed by Airwolf, is a positive pressure system. It's actually connected to a vacuum pump outlet or upper plenum pressure. All the others run at near case pressure, or lower if connected to a pump (common in auto racing) or an exhaust vacuum tap (Cubcrafters, Mooney, Cirrus, TAT, Sky Dynamics, and yes, Horton).

Dan you made a logical fallacy called an appeal to authority, and strawman argument, rebuttal to a point not asked or disputed, meaningless, not addressing my comment. I never said air/oil separators can’t condense the vent tube stuff back into a liquid. Also how many thousands of certified planes and EAB kit planes have been produced and flown happily for countless hours WITH NO AIR OIL SEPERATOR?

Old days GA air/oil separators were for WET Vacuum pumps. My 1958 Piper PA23-160 Apache (twin) older then me I swear ha ha, had wet vacuum pumps and aftermarket oil catchers on the vac pump exits. The engine? Nope. Oil coming out the wet vac pumps had no combustion products and nil water.

Doo-dads, F-arkle (Functional Sparkle), fun things to add, not too expensive, promise a lot, and they are hard for kit builder/owners to resist. They tend to be benign. I'm making a point of moisture and “nasty” acid stuff. The damage if any is nominal. My point is why, weight, cost, clutter, and questionable benefit. People like to customize and accessorize their car, motorcycle and plane. I get it. Fun. Looks cool and PFM. No proof of benefit needed.

I see used Airwolf’s (Walker) for sale. Many people put them on and are unhappy with them not delivering on claims. Beech Bonanza guy installed one due to high oil use on his old Continental, thinking it was a solution, not new rings, cylinders, valve guides. Many Airwolf's (made of steel) RUST OUT… Impressive? No.

Air Wolf has “positive pressure”. So? Does that mean all the many other passive A/O separators are inferior? They all return garbage back to the engine to some degree. Airwolf is tied to vacuum pump. Anyone running a vacuum pump anymore on newer planes Std or EAB Cert? Glass, solid state gyros made wet/dry vacuum pumps go the way of the buggy whips.

BTW: Race cars have oil collection due to racing league rules (track contamination) or to make more HP by evacuating the crank case even if oil consumption goes up.

Very simple:

Pro Air/Oil Separator – May keep belly cleaner? (I never saw a big difference as others also observe.

NOTE Fill engine oil Max oil 5-6 qts. Put 8 qts blow off 2 qts quickly)

Con Air/Oil Separator – Adds weight, cost, clutter, and may cause faster oil contamination and/or increase average internal engine moisture and higher crank case pressures due to flow restriction.

Bottom: Line: Up to the builder/owner to decide if this extra engine accessory is valuable.

DanH;1670937Return I don't...except at cold start said:

or[/I] hot blowby contains oil droplets. Water in liquid phase is indeed separated and returned to the engine...but comes right back out, in vapor phase, when it reaches operating temperature. Without an engine return line, the short cold period is when your catch can collects water. .

Dan 1st class rationalization. You spend time, money to mount that polished beauty on your firewall. Pretty. You are invested emotionally. It is like the Placebo effect in medication. You believe it “works” it does. It is not 100% bad or good. What I know and have observed, seeing dozens of air/oil designs come and go, calming all kinds of things, bashing other brands, has shown me they are NOT A MUST HAVE (for me).

I am NOT saying all Air/Oil separators are bad, just

not value added enough for me to install one and drain the snot back into the engine. Done that been there. Fool me once... I do think some designs are clearly problematic. The ones that can clog for one (like the pot scrubber one in EAA literature, and ASA also has pot scrubber inside in the "can" I recall). Net Negative or Positive for A/O separators? IMHO Nil benefit and possibly (slightly/potentially) detrimental. It's a solution for a problem that does not exist. Take it or leave it. OIL ON BELLY? Stop putting in 8qts in your engine... 5-6qts is all you need. Put more it blows out quickly.

I personally ran many-O-plenty air/oil separators. They do catch water vapor and oil and stuff. Water is oily and the oil has water and combustion products mixed in it. It really looks awful. Left to sit for days it does stratify but not completely. You could put this snot through a processes to separate all the good from bad components, but it takes lab equipment and centrifuge. A HOT metal “can” on the firewall can not do this, at least completely.

You admit two things. It is acidic to a degree. Second A/O Separator adds more moisture to engine after initial start up or taxi back when engine and engine bay are cool. This prevents drying of engine, at least for a period until engine and separator are HOT. Many people take short flights. What about winter and long taxi to and from ramp with cool engine and cool air/oil separator. You shut down after a long taxi back to hanger and send a slug of water into the engine before shutting down. It sits until next flight which could be days, weeks or months. You claim the A/O Sep is so hot water burns off? Nope it is cooling as soon as it leaves engine and mixes with cool air in hoses and can. All this is enough for me to avoid draining condensate back into engine from an air/oil separator.

My observations without air/oil separator was my oil consumption did not change and belly was not that dirty before or after. In fact that is a complaint of many people who install these things. They DO NOT WORK AS PROMISED. Of course the inventor/manufacture says you did not do it right. I reserve the right to be wrong. I see you have conceded my two main points, acidic to some degree and moisture can get regurgitated back into engine. I think we are done.