AirbusPilot

Well Known Member

Hi Folks,

Yesterday I was flying with a passenger in my 8 who is not a pilot but he has flown with me a few time before, I always let him to fly the plane because he wants to become a pilot (he is rebuilding an ultralight) also he helped me when I was building.

My passenger was flying and I was teaching him how to trim the plane (I have infinity grips with electric flaps and trim), we were flying at 140kt when I felt the plane strange so I said "I have control" and started to trim in again but the plane still feel strange, there were I saw my flaps down about 20 degrees

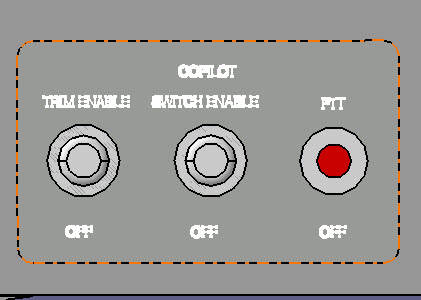

Max speed with flaps down is 87kts and I was flying at 140kts, I have a kill switch for the rear stick button but I leave it on, I checked the flaps after landing and everything looks fine but only thinking about what could happens if he lower all flap down

I feel very bad because what I have done, a big flap failure and I could lost control of my plane with terrible result for me, my family and the entire expirimental group, maybe thinking their is a problem with the plane.

Leasson learned, that switch must be off all time and no more non pilot passenger flying my 8!!!

Yesterday I was flying with a passenger in my 8 who is not a pilot but he has flown with me a few time before, I always let him to fly the plane because he wants to become a pilot (he is rebuilding an ultralight) also he helped me when I was building.

My passenger was flying and I was teaching him how to trim the plane (I have infinity grips with electric flaps and trim), we were flying at 140kt when I felt the plane strange so I said "I have control" and started to trim in again but the plane still feel strange, there were I saw my flaps down about 20 degrees

Max speed with flaps down is 87kts and I was flying at 140kts, I have a kill switch for the rear stick button but I leave it on, I checked the flaps after landing and everything looks fine but only thinking about what could happens if he lower all flap down

I feel very bad because what I have done, a big flap failure and I could lost control of my plane with terrible result for me, my family and the entire expirimental group, maybe thinking their is a problem with the plane.

Leasson learned, that switch must be off all time and no more non pilot passenger flying my 8!!!

Last edited: