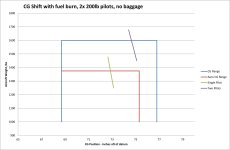

My RV-6 weighed 1127lb when I bought it – rather too much but there were some compelling reasons why that was not a deal breaker such as an angle valve motor. When it was built 20 years ago the choices made were entirely sensible, but the world has moved on. It is now time for a diet. The aim is for an empty weight below 1050lb and to shift the empty cg rearwards, currently it is at 69.2” aft.

This project will take several weeks, some of the parts are still in transit!

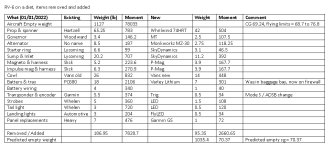

I have made a prediction for the weight that can be saved, current estimate is 1035.4lb empty weight. Yesterday I started by removing many of the engine accessories and weighing them, so I know most of the weights in the attached table are correct. Going to be interesting to see what the eventual result is. I'm not smart enough to format a table here so have attached a picture of what I am planning.

Headline items that save the most weight

Prop, Hartzell removed Whirlwind fitted (-23lb)

Battery, PC680 removed Varley Lithium fitted (-10lb)

Cowling, old uncored version removed new cored cowl fitted (-15lb)

Sump & inlet. Lycoming items removed SkyDynamics Maxisump fitted (-9lb)

Alternator, regular front mount alt removed Monkworkz fitted with light SkyDynamics starter ring (-9lb)

Changes in the panel, including new transponder (-12lb)

Lighting changes, replacing incandescent with LED (-7lb)

Pete

This project will take several weeks, some of the parts are still in transit!

I have made a prediction for the weight that can be saved, current estimate is 1035.4lb empty weight. Yesterday I started by removing many of the engine accessories and weighing them, so I know most of the weights in the attached table are correct. Going to be interesting to see what the eventual result is. I'm not smart enough to format a table here so have attached a picture of what I am planning.

Headline items that save the most weight

Prop, Hartzell removed Whirlwind fitted (-23lb)

Battery, PC680 removed Varley Lithium fitted (-10lb)

Cowling, old uncored version removed new cored cowl fitted (-15lb)

Sump & inlet. Lycoming items removed SkyDynamics Maxisump fitted (-9lb)

Alternator, regular front mount alt removed Monkworkz fitted with light SkyDynamics starter ring (-9lb)

Changes in the panel, including new transponder (-12lb)

Lighting changes, replacing incandescent with LED (-7lb)

Pete